China 7075 Aluminum Wires Suppliers & Manufacturers

If you are looking for high-quality 7075 aluminum wire, our team of suppliers and manufacturers provide you with quality products. Known for its high strength, corrosion resistance, and lightweight properties, 7075 aluminum wire is widely used in aerospace, automotive manufacturing, and industrial fields. We have sufficient inventory to ensure fast delivery to meet your urgent needs.

7075 aluminum wire is one of the strongest aluminum alloys available, known for its excellent strength-to-weight ratio, outstanding fatigue resistance, and good machinability. It is widely used in aerospace, automotive, military, and other industries where reliability and performance are critical.

If you are looking for a reliable 7075 aluminum wire supplier, comprehensive pricing information, or questions about its applications and benefits, please contact us directly!

(A97075) 7075 Aluminum Wire Specifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: O, T651, T3, T451, T4,T6, T76, T73, T7351, F, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: AMS 4122 7075-T6、AMS 4124 7075-T7351、AMS 4186 7075-TF、AMS 4187 7075-0, etc.

Delivery Time: 7-20 days.

7075 Aluminum Wire Data Sheet

Equivalent Grades Of Aluminum 7075 Wire

| Standard | 7075 Aluminum | Equivalent Grades | Notes |

|---|---|---|---|

| Aluminum Association (AA) | 7075 | – | Standard aluminum alloy designation |

| International Organization for Standardization (ISO) | 7075 | 3.4365 | Comparable performance to 7075 |

| Deutsches Institut für Normung (DIN) | – | EN AW-7075 | Standard corresponding designation |

| British Standards (BS) | – | 7075-T6 | 7075-T6 is commonly used interchangeably |

| Japanese Industrial Standards (JIS) | – | A7075-T6 | A7075-T6 is similar under JIS standards |

| Chinese National Standards (GB) | – | 7075-T6 | 7075-T6 is often used as an equivalent |

Chemical Composition of 7075 Aluminum Wire

| Element | Chemical Composition (%) |

|---|---|

| Al | Balance (approximately 87.1 – 91.4%) |

| Zn | 5.1 – 6.1% |

| Cu | 1.2 – 2.0% |

| Mg | 2.1 – 2.9% |

| Mn | 0.3% max |

| Cr | 0.18 – 0.28% |

| Si | 0.4% max |

| Fe | 0.5% max |

| Ti | 0.2% max |

| Other Elements | Each 0.05% max, Total 0.15% max |

Mechanical Properties and Tempers of 7075 Aluminium Wire

| Property | 7075-T6 | 7075-T651 | 7075-T7 | 7075-T76 |

|---|---|---|---|---|

| Yield Strength (MPa) | 503 – 572 | 483 – 552 | 414 – 482 | 483 – 552 |

| Ultimate Tensile Strength (MPa) | 572 – 641 | 552 – 621 | 483 – 552 | 552 – 621 |

| Elongation (%) | 8 – 10 | 10 – 12 | 8 – 10 | 10 – 12 |

| Shear Strength (MPa) | 414 – 517 | 414 – 482 | 414 – 482 | 414 – 482 |

| Hardness (Brinell) | 150 – 180 | 145 – 175 | 150 – 180 | 145 – 175 |

For high-quality 7075 aluminum wire and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7075 Aluminum Wires Metal

7075 aluminum wire metal is renowned for its high strength and versatility, making it suitable for various demanding applications. The properties of 7075 aluminum can vary significantly depending on its temper, which refers to the heat treatment and aging process it undergoes. Here’s a breakdown of the most common tempers for 7075 aluminum wire metal:

7075-T6

- Properties: This is one of the most widely used tempers for 7075 aluminum. It offers the highest strength and is known for its excellent mechanical properties. It has good resistance to stress corrosion cracking and is often used in aerospace and structural applications.

- Applications: Aircraft structures, marine components, and high-stress components.

7075-T651

- Properties: Similar to T6 but with a slightly different processing method that reduces internal stresses. It has the same high strength as T6 but with improved machinability.

- Applications: Aerospace components, high-strength structural parts, and tooling.

7075-T73

- Properties: This temper is an alternative to T6, with similar strength but enhanced stress corrosion resistance and improved toughness. It undergoes a solution heat treatment followed by aging at a lower temperature.

- Applications: Aerospace parts requiring good corrosion resistance and strength, such as fuselage frames and wing skins.

7075-T76

- Properties: This is an alternative to T73 with similar mechanical properties but offers improved resistance to localized corrosion.

- Applications: Specialized aerospace components and high-performance marine applications.

7075-O

- Properties: The ‘O’ temper denotes that the aluminum is in its soft, annealed state. This temper is not as strong as T6 but provides the maximum ductility and is easier to form and machine.

- Applications: Pre-machining or forming, and applications requiring extensive shaping.

7075-T3 and 7075-T4

- Properties: These are less commonly used but are still relevant. T3 is a solution heat-treated and cold-worked, offering good strength and formability. T4 is similar but requires additional aging for increased strength.

- Applications: Aerospace and military applications, where high strength and corrosion resistance are necessary.

If you’re unsure which temper is best for your needs, consult us, we are an aluminum metal supplier or manufacturer to ensure the right material is selected for your project.

Applications of 7075 Aluminum Wire Alloy

Aerospace

For aircraft frames, structural components, and landing gear.

Automotive

Key components for high-performance and racing vehicles, such as suspension components and engine parts.

Defense and Military

For ballistic applications, firearms, and military-grade equipment.

Industrial Uses

Equipment requiring high strength and wear resistance, such as hydraulic systems and robotic arms.

Sports and Leisure Equipment

For high-end bicycles, climbing equipment, and golf clubs.

As a leading 7075 aluminum wire manufacturer, we use advanced production technology and a strict quality control system to ensure that each batch of products meets international standards. Our supplier network covers the world and can provide you with a variety of specifications and customized services. Whether it is a small batch purchase or a large-scale order, we can meet your needs with reasonable 7075 aluminum wire prices and fast delivery capabilities. Contact us now to get our aluminum wire inventory, their prices, etc.!

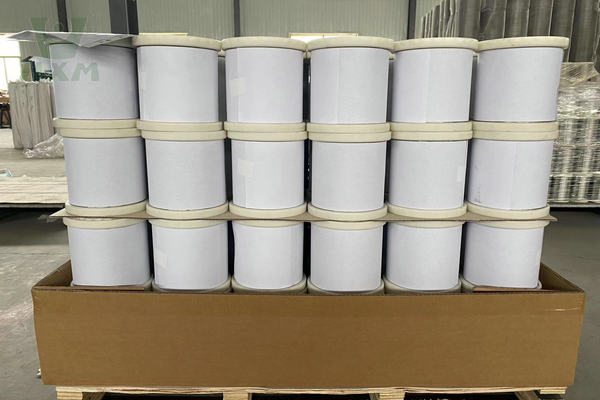

7075 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 7075 Aluminum Wire?

7075 aluminum wire belongs to the 7000 series aluminum alloy, which is mainly composed of zinc and small amounts of magnesium, copper and chromium. This alloy was developed specifically for aerospace applications, and its unique combination of properties makes it an indispensable material in high-performance engineering. If you need to know other questions, you can contact us directly!

Features of 7075 Aluminum Wire:

Exceptional Strength

Boasts one of the highest strength levels among aluminum alloys, comparable to some steels.

Outstanding Fatigue Resistance

Performs reliably in cyclic loading conditions, making it ideal for dynamic applications.

Lightweight

Provides excellent strength without adding unnecessary weight, making it a preferred choice for aerospace and automotive designs.

Corrosion Resistance

Good corrosion resistance when properly coated or anodized.

Good Machinability

Easy to work with despite its high strength, supporting precision engineering needs.

Advantages of 7075 Aluminum Wire:

Performance Under Pressure

Handles high-stress environments with ease, ensuring safety and reliability.

Weight Savings

It reduces overall weight without compromising strength, a critical factor for the aerospace and automotive industries.

Customizable Tempers

Available in various tempers, such as T6 and T73, tailored to meet specific needs.

Eco-Friendly Solution

Fully recyclable, supporting sustainability initiatives.

Is 7075 Aluminum Wire suitable for welding?

7075 Aluminum Wire is not as weldable as some other alloys due to its high zinc content. Specialized welding techniques are required for best results.

Why Choose Us As Your 7075 Aluminum Wire Supplier?

At HXM, we offer:

Competitive Prices: Cost-effective solutions for bulk orders.

Custom Sizes and Tempers: Tailored products to meet your specifications.

Fast Shipping: Global delivery with quick turnaround times.

HXM is a trusted name in aluminum products, offering 7075 Aluminum Wire with guaranteed quality and competitive prices. Contact us for a free quote or detailed pricing information today!

What tempers are available for 7075 Aluminum Wire?

Common tempers include T6 (optimized for strength) and T73 (enhanced corrosion resistance).

How does 7075 Aluminum Wire compare to stainless steel?

While 7075 Aluminum Wire is significantly lighter than stainless steel, it offers comparable strength in many applications, making it a preferred choice for weight-sensitive projects.