5356 aluminum wire is a high-magnesium alloy known for its strength, corrosion resistance, and excellent welding properties. This alloy is widely used in applications where durability is required, especially in marine and structural environments.

For pricing, availability, and additional support for 5356 aluminum wire, contact our team today for a free quote, assistance, and more.

5356 Aluminum WireSpecifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: O, H32, H34, H36, H38, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: ISO9001, CE, SGS, etc

Delivery Time: 7-20 days.

5356 Aluminum Wire Data Sheet

Chemical Composition of 5356 Aluminum Alloy Wire

| Element | Percentage (%) |

|---|---|

| Al | Balance |

| Mg | 4.5–5.5 |

| Mn | 0.05–0.20 |

| Cr | 0.05–0.20 |

| Si | ≤ 0.25 |

| Fe | ≤ 0.40 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.06 |

Mechanical Properties of 5356 Aluminum Alloy Wire

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| O (Annealed) | 210–240 | 95–120 | ≥ 14 |

| H32 | 270–310 | 200–240 | ≥ 10 |

| H34 | 290–330 | 230–270 | ≥ 8 |

| H36 | 310–350 | 260–300 | ≥ 7 |

| H38 | 330–370 | 280–320 | ≥ 6 |

Physical Properties of 5356 Aluminum Wire

| Property | Value |

|---|---|

| Density | 2.66 g/cm³ |

| Melting Point | 607–645°C |

| Electrical Conductivity | 30% IACS |

| Thermal Conductivity | 121 W/m·K |

Equivalent Grades for 5356 Aluminum Wire

| Standard | Equivalent Grade |

|---|---|

| AWS | A5.10 ER5356 |

| UNS | A95356 |

| ISO | ISO AlMg5 |

| EN | AW 5356 |

There are some differences in the chemical composition of aluminum products from different aluminum manufacturers, but they are all within a certain range. If you want to know more, please contact us directly!

Applications of 5356 Aluminum Wires Metal

Welding Applications: Widely used as a filler material for aluminum-magnesium alloys in MIG and TIG welding.

Marine Industry: Ideal for shipbuilding, boat hulls, and components exposed to saltwater.

Automotive Sector: Used in structural reinforcements and lightweight components.

Industrial Manufacturing: Applied in the production of rivets, fasteners, and electrical wires.

Architectural Projects: Perfect for decorative panels, railings, and other corrosion-resistant installations.

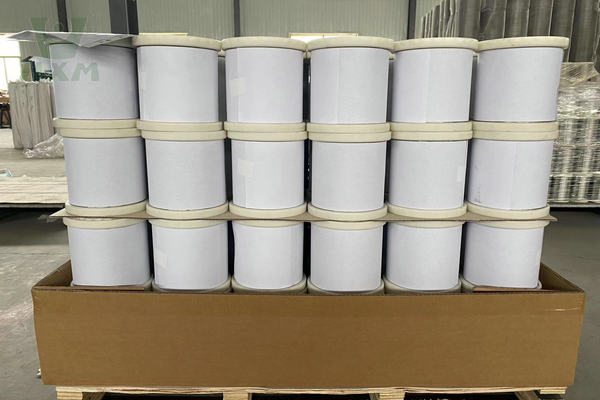

5356 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

Is 5356 Aluminum Wire Weldable?

Yes, 5356 aluminum wire is highly weldable and is widely used in MIG and TIG welding for joining aluminum-magnesium alloys.

Features of 5356 Aluminum Wire

Superior Corrosion Resistance: Withstands harsh marine environments and chemical exposure.

High Strength: Delivers excellent mechanical performance, even in demanding applications.

Excellent Weldability: Compatible with MIG and TIG welding processes.

Wide Range of Applications: Suitable for industries including marine, construction, and automotive.

What Industries Use 5356 Aluminum Wire?

It is commonly used in the marine, automotive, aerospace, and construction industries due to its excellent corrosion resistance and strength.

Why Choose Us As Your 5356 Aluminum Wire Supplier?

Reliable Performance: Offers excellent corrosion resistance and strength in various applications.

Custom Sizes Available: We provide wire in different diameters and packaging options.

Global Export Expertise: Trusted by customers worldwide with a proven track record of timely delivery.

Competitive Pricing: Affordable rates for bulk orders with guaranteed quality.

What is the difference between 4043 and 5356 aluminum wire?

Composition:

- 4043 Aluminum Wire: Contains a higher percentage of silicon (~5%), making it ideal for joining aluminum alloys with a low magnesium content.

- 5356 Aluminum Wire: Contains a higher magnesium content (~5%), providing better corrosion resistance, especially in marine environments.

Strength:

- 4043: Offers moderate strength and is often used for non-structural applications.

- 5356: Has higher tensile strength, suitable for structural and load-bearing applications.

Corrosion Resistance:

- 4043: Moderate corrosion resistance, primarily for indoor or less harsh environments.

- 5356: Superior corrosion resistance, especially effective against saltwater and marine exposure.

Weldability:

- 4043: Provides smoother welding with reduced cracking but is less suitable for high-stress applications.

- 5356: Excellent for MIG/TIG welding in structural and outdoor applications.

Applications:

- 4043: Commonly used in automotive, general repairs, and casting applications.

- 5356: Preferred for marine, aerospace, and structural components.

Choose 4043 for smoother welds and moderate environments, and 5356 for strength and corrosion resistance in harsher settings.

4043 Aluminum Wires