5154 aluminum wire is an aluminum-magnesium alloy that is widely acclaimed for its high strength, excellent corrosion resistance, and outstanding weldability. It is ideal for applications requiring reliability in marine, structural, and industrial environments.

Looking for a reliable 5154 aluminum wire supplier? Contact Huaxiao Metal today:

- Customized quote based on your requirements.

- Detailed information on stock availability and shipping options.

- Expert advice on the best alloy for your application.

5154 Aluminum Wire Specifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: O, H12, H22, H32, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: ISO9001, CE, SGS, etc

Delivery Time: 7-20 days.

5154 Aluminum Wire Data Sheet

Equivalent Grades Of 5154 Aluminum Wire

| Standard/Organization | 5154 Aluminum Alloy | Equivalent Grade |

|---|---|---|

| ISO Standard | ISO 6362-3 | AlMg3 |

| European Standard | EN AW-5154 | EN AW-5154 |

| British Standard | BS 1470 | L3 |

| ASTM Standard | ASTM B209 | – |

| JIS Standard | JIS H 4000 | A5052 |

| DIN Standard | DIN 3.3523 | – |

Chemical Composition of 5154 Aluminum Wire

| Element | Percentage Range |

|---|---|

| Al | Balance |

| Mg | 2.4% – 3.0% |

| Mn | 0.40% – 0.80% |

| Cr | 0.05% – 0.25% |

| Si | 0.10% max |

| Cu | 0.10% max |

| Zn | 0.10% max |

| Fe | 0.40% max |

| Other Elements | 0.15% max each, 0.30% total |

Mechanical Properties of 5154 Aluminium Wire with Different Tempers

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| 5154 O (Annealed) | 120 – 175 | 45 – 75 | 30 – 50 | 40 – 60 |

| 5154-H12 (Work Hardened) | 185 – 235 | 105 – 145 | 20 – 30 | 60 – 75 |

| 5154-H22 (Work Hardened & Partially Annealed) | 185 – 235 | 105 – 145 | 20 – 30 | 60 – 75 |

| 5154-H32 (Work Hardened & Solution Heat Treated) | 200 – 250 | 140 – 180 | 15 – 25 | 70 – 85 |

For high-quality 5154 aluminum wire and professional assistance, contact HXM, your reliable supplier of aluminum products.

Physical Properties of 5154 Aluminum Wire Metal

| Property | Value | Units |

|---|---|---|

| Density | 2.68 – 2.72 | g/cm³ |

| Melting Point | 605 – 650 | °C |

| Thermal Conductivity | 120 – 140 | W/m·K |

| Electrical Conductivity | 30 – 40 | % IACS* |

| Specific Heat Capacity | 0.897 | J/g·K |

| Modulus of Elasticity | 69 – 71 | GPa |

| Poisson’s Ratio | 0.33 | – |

| Thermal Expansion Coefficient | 22.7 x 10^-6 | /°C |

| Surface Finish | Smooth, can be anodized or coated | – |

Different Tempers of 5154 Aluminum Wires Metal

O (Annealed): This temper involves heating the aluminum to a high temperature and then slowly cooling it to relieve internal stresses and soften the material. It is suitable for applications requiring high formability and ease of machining.

H12 (Work Hardened): This temper is achieved by cold working the aluminum, which increases its strength and hardness. It is commonly used in applications where moderate strength and good workability are needed.

H22 (Work Hardened & Partially Annealed): This temper combines work hardening with partial annealing. The partial annealing reduces some of the hardness and brittleness, offering a balance between strength and ductility.

H32 (Work Hardened & Solution Heat Treated): This temper involves solution heat treatment followed by work hardening. It provides higher strength and improved mechanical properties compared to the O and H12 tempers while retaining good ductility.

Applications of 5154 Aluminum Sheet Metal

Marine Applications

Cabling, rigging, and components exposed to saltwater.

Automotive Industry

Lightweight structural parts and electrical systems.

Construction Sector

Structural reinforcements and frameworks.

Industrial Uses

Chemical processing equipment and storage tanks.

Aerospace Industry

Parts where lightweight and corrosion-resistant are critical.

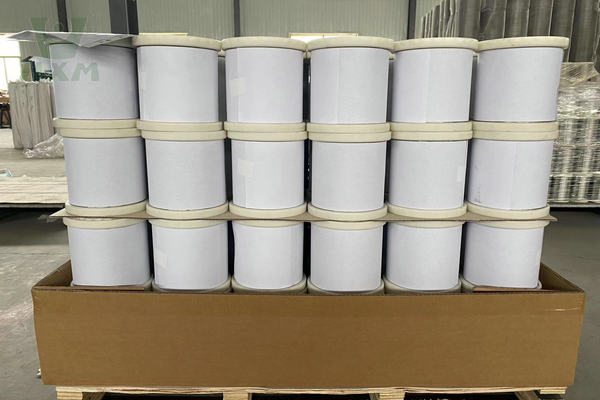

5154 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 5154 Aluminum Wire?

5154 aluminum wire belongs to the 5000 series aluminum alloys, known for its high magnesium content and excellent performance in harsh environments. The alloy is particularly suitable for marine applications because it resists corrosion from salt water.

Features of 5154 Aluminum Wire:

Excellent Corrosion Resistance

- Ideal for marine and chemical-exposed environments.

High Tensile Strength

- Ensures durability and performance in heavy-duty applications.

Good Weldability

- Compatible with most welding techniques, maintaining strength after welding.

Lightweight and Flexible

- Combines strength and lightness, making it easy to handle and install.

Eco-Friendly

- Fully recyclable, supporting sustainable practices.

5154 Aluminum Wire vs Other Alloys:

| Property | 5154 Aluminum Wire | 5052 Aluminum Wire | 5083 Aluminum Wire |

|---|---|---|---|

| Corrosion Resistance | Excellent | Excellent | Excellent |

| Strength | High | Moderate | Very High |

| Weldability | Good | Excellent | Excellent |

Why Choose Us As Your 5154 Aluminum Wire Supplier?

At HXM, we are a leading supplier and manufacturer of 5154 Aluminum Wire, offering:

Competitive Prices: Affordable solutions for both large and small orders.

Quick Availability: Ready-to-ship inventory for your immediate needs.

Customization Services: Tailored specifications to suit diverse applications.

Durability for Tough Environments: Performs reliably in saltwater and industrial conditions.

Cost-Effective: Long-lasting performance reduces maintenance costs.

Customizable Options: Available in various sizes, tempers, and finishes.