5083 Aluminum Wire is a premium aluminum alloy known for its superior strength, corrosion resistance, and versatility. This alloy is widely used in marine, automotive, and industrial applications where durability and reliability are critical.

If you are looking for 5083 Aluminum Wire suppliers, manufacturers, or their price information, please contact us directly!

5083 Aluminum Wire Specifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: O, H111, H112, H116, H321, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: ISO9001, CE, SGS, etc

Delivery Time: 7-20 days.

5083 Aluminum Wire Data Sheet

Equivalent Grades Of Aluminum Wire 5083

| Standard | Equivalent Grade |

|---|---|

| ASTM (American) | ASTM B209 5083 |

| EN (European) | EN AW-5083 |

| DIN (German) | DIN 3.3547 |

| JIS (Japanese) | JIS A5052 (similar) |

| ISO (International) | ISO 209-1 (similar) |

Chemical Composition of Aluminum Wire 5083

| Al | Mg | Mn | Cr | Cu | Zn | Si | Fe |

|---|---|---|---|---|---|---|---|

| Balance | 4.0% – 4.9% | 0.40% – 0.70% | 0.05% – 0.25% | ≤ 0.10% | ≤ 0.10% | ≤ 0.10% | ≤ 0.40% |

Mechanical Properties of 5083 Aluminium Wires with Different Tempers

| Temper | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

5083 O (Soft) | 110 – 140 | 250 – 290 | 18 – 25 | 60 – 80 |

| 5083-H111 (H1) | 140 – 180 | 290 – 320 | 15 – 20 | 80 – 100 |

| 5083-H112 (H2) | 150 – 190 | 320 – 350 | 15 – 20 | 80 – 100 |

| 5083-H116 | 170 – 220 | 330 – 350 | 12 – 15 | 90 – 110 |

| 5083-H321 | 170 – 220 | 330 – 350 | 12 – 15 | 90 – 110 |

For high-quality 5083 aluminum wire and professional assistance, contact HXM, your reliable supplier of aluminum products.

Physical Properties of 5083 Aluminum Wire Metal

| Property | Value |

|---|---|

| Density | Approximately 2.66 g/cm³ (2660 kg/m³) |

| Melting Point | 650 – 660°C (1202 – 1220°F) |

| Thermal Conductivity | About 120 W/m·K |

| Electrical Conductivity | Approximately 30% IACS (International Annealed Copper Standard) |

| Specific Heat Capacity | About 900 J/kg·K (0.215 BTU/lb·°F) |

| Young’s Modulus | 70 – 72 GPa (10,000 – 10,500 ksi) |

| Thermal Expansion Coefficient | Approximately 23 x 10⁻⁶ /K |

| Sound Velocity | Approximately 6400 m/s (21,000 ft/s) |

Different Tempers of 5083 Aluminum Wires Metal

O Temper (Soft): Offers maximum ductility and formability but with lower strength. Ideal for applications where the metal needs to be easily shaped.

H111: Provides moderate strength and improved machinability compared to the O temper.

H112: Offers a good balance of strength and workability, suitable for many structural applications.

H116: Specifically designed for marine applications due to its high resistance to corrosion and stress corrosion cracking.

H321: Provides enhanced stress corrosion resistance compared to H116, often used in more demanding marine or industrial environments.

Applications of 5083 Aluminum Wire Metal

Marine Industry

Used in rigging, cabling, and components exposed to saltwater.

Automotive Industry

Suitable for structural parts and electrical wiring in lightweight vehicles.

Industrial Manufacturing

Ideal for machinery requiring both strength and corrosion resistance.

Aerospace Industry

Applied in components where lightweight and durability are essential.

Construction

Used in architectural frameworks and load-bearing applications.

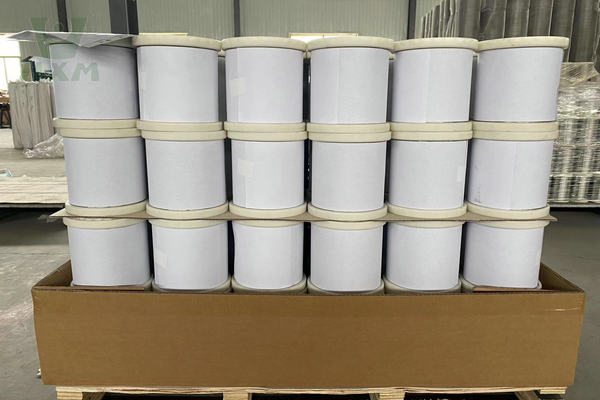

5083 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 5083 Aluminum Wire?

5083 aluminum wire is an alloy that is primarily aluminum, with a high amount of magnesium and trace amounts of manganese and chromium. This composition gives it excellent corrosion resistance, especially in marine environments. Its high strength and excellent weldability make it ideal for demanding applications.

Features of 5083 Aluminum Wire

Exceptional Corrosion Resistance

Performs exceptionally in saltwater and chemical-rich environments.

High Strength

Offers excellent mechanical properties, suitable for heavy-duty applications.

Outstanding Weldability

Compatible with most welding techniques without compromising performance.

Superior Formability

Can be shaped into complex structures while maintaining its strength.

Lightweight and Durable

Provides high performance with reduced weight, ideal for transportation and structural applications.

5083 Aluminum Wire vs Other Alloys

| Property | 5083 Aluminum Wire | 5052 Aluminum Wire | 6061 Aluminum Wire |

|---|---|---|---|

| Corrosion Resistance | Excellent | Excellent | Good |

| Strength | Very High | High | Very High |

| Weldability | Excellent | Excellent | Good |

Why Choose Us As Your 5083 Aluminum Wire Supplier?

At HXM, we are dedicated to providing high-quality 5083 Aluminum Wire. As trusted manufacturers and suppliers, we offer:

Durability in Harsh Environments

- Perfect for marine, industrial, and chemical exposure.

Cost-Efficient Material

- Long-lasting performance minimizes maintenance and replacement costs.

Sustainable Choice

- Fully recyclable, supporting eco-friendly practices.

Looking for reliable 5083 aluminum wire suppliers? Contact us today to receive the best pricing and discover how our 5083 Aluminum Wire can elevate your projects.