At HXM, we offer premium 3005 aluminum wire, known for its superior strength, corrosion resistance, and versatility. As an upgrade from the 3003 alloy, 3005 aluminum wire offers enhanced durability, making it ideal for industrial and commercial applications.

Whether you are looking for a 3005 aluminum wire supplier, exploring 3005 aluminum wire prices, or need bulk stock for a large project, we are your trusted partner.

3005 Aluminum WireSpecifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: O,H12,H14,H16,H18,H19,H22,H24,H26,H28, ect.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: ISO9001, CE, SGS, etc

Delivery Time: 7-20 days.

3005 Aluminum Wire Data Sheet

Equivalent Of Aluminum 3005 Wire

| Country/Region | Standards Organization | Standard | Description |

|---|---|---|---|

| USA | ASTM | ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| Europe | EN | EN 485-2 | Aluminum and Aluminum Alloys – Sheet, Strip and Plate – Mechanical Properties |

| Japan | JIS | JIS H4000 | Aluminum and Aluminum Alloy Sheets and Plates |

| China | GB | GB/T 3880 | Aluminum and Aluminum Alloy Plates, Sheets, and Strips |

| Germany | DIN | DIN 1725 | Aluminum and Aluminum Alloys – Sheets and Plates |

| International | ISO | ISO 6361-2 | Wrought Aluminum and Aluminum Alloy Sheets, Strips, and Plates – Mechanical Properties |

Chemical Composition of 3005 Aluminum Wire

| Element | Al | Mn | Mg | Cu | Fe | Si | Zn | Cr | Other, each | Other, total |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 96.8 – 98.6 | 1.0 – 1.5 | 0.2 – 0.6 | ≤ 0.30 | ≤ 0.7 | ≤ 0.6 | ≤ 0.25 | ≤ 0.1 | ≤ 0.05 | ≤ 0.15 |

Notes:

Al: The remainder of the composition is aluminum.

Mn: Added to increase strength and hardness.

Mg: Improves the strength and workability.

Cu, Fe, Si, Zn, Cr: Present in controlled amounts to enhance specific properties and performance characteristics.

Other elements: Trace amounts of other elements are present, each limited to 0.05%, and the total cannot exceed 0.15%.

Mechanical Properties and Tempers of 3005 Aluminium Wire

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

| H12 | 130 – 170 | 90 – 110 | 12 – 14 | ~45 HB |

| H14 | 140 – 185 | 100 – 125 | 10 – 12 | ~46 HB |

| H16 | 150 – 195 | 110 – 135 | 8 – 10 | ~47 HB |

| H18 | 160 – 205 | 120 – 145 | 8 – 9 | ~48 HB |

| H22 | 130 – 175 | 95 – 115 | 12 – 14 | ~45 HB |

| H24 | 140 – 185 | 105 – 130 | 10 – 12 | ~46 HB |

| H26 | 150 – 195 | 115 – 140 | 8 – 10 | ~47 HB |

| H28 | 160 – 205 | 125 – 150 | 8 – 9 | ~48 HB |

| H32 | 130 – 170 | 90 – 115 | 12 – 14 | ~45 HB |

| H34 | 140 – 185 | 100 – 125 | 10 – 12 | ~46 HB |

| H36 | 150 – 195 | 110 – 135 | 8 – 10 | ~47 HB |

| H38 | 160 – 205 | 120 – 145 | 8 – 9 | ~48 HB |

For high-quality 3005 aluminum Wire and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 3005 Aluminum Wires

Strain-Hardened (H12, H14, H16, H18): These tempers involve increasing hardness through cold working. The numbers indicate the degree of strain hardening, with H18 being the hardest.

Strain-Hardened and Partially Annealed (H22, H24, H26, H28): These tempers involve a combination of strain hardening and partial annealing to improve formability while retaining some hardness.

Strain-Hardened and Stabilized (H32, H34, H36, H38): These tempers provide stability in mechanical properties, combining strain hardening with stabilization treatments to enhance strength and durability.

Looking for competitive 3005 Aluminum Wire prices? At HXM, we offer transparent pricing and flexible order quantities to meet your specific needs.

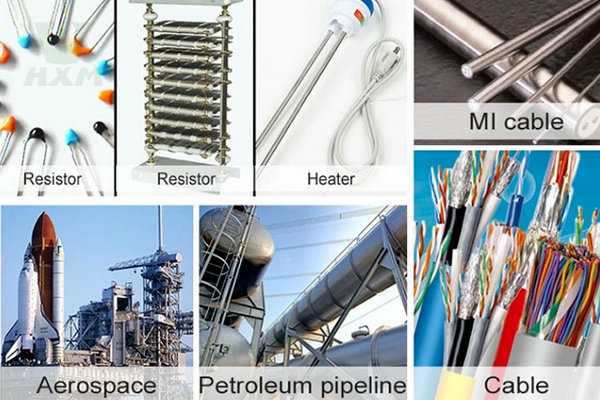

Applications of 3005 Aluminum Wire Metal

Electrical Industry: Reliable for wiring, cables, and conductors.

Construction: Ideal for roofing, siding, and architectural components.

Transportation: Lightweight and durable for use in vehicles, trains, and ships.

Packaging: Commonly used in producing closures, lids, and other packaging solutions.

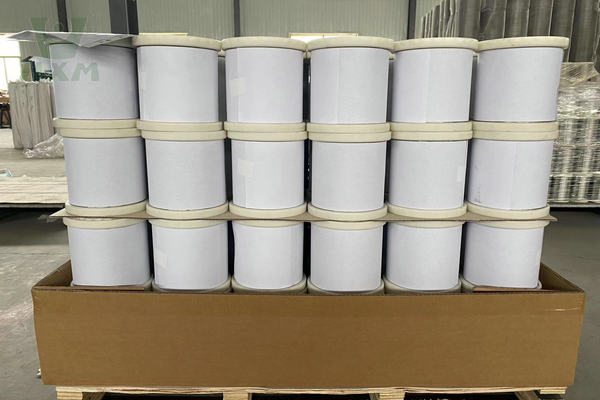

3005 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What is 3005 Aluminum Wire?

3005 aluminum wire is a high-strength alloy wire made of aluminum and a small amount of manganese. 3005 aluminum wire is known for its durability, corrosion resistance, and electrical conductivity and is used in a wide variety of industries. It belongs to the 3000 series of aluminum alloys, which are known for their excellent formability and corrosion resistance, making them suitable for both indoor and outdoor applications.

Looking for a reliable 3005 aluminum wire supplier? Huaxiao Metal offers high-quality 3005 aluminum wire with excellent conductivity and corrosion resistance. Our aluminum wire is ideal for a variety of applications, including electrical wires, industrial uses, and automotive parts. Contact us today for bulk orders and competitive pricing!

Features of 3005 Aluminum Wire

Superior Corrosion Resistance: Excellent performance in humid or chemically aggressive environments.

High Strength: Greater tensile strength compared to 3003, suitable for structural and heavy-duty applications.

Lightweight: Provides strength without adding unnecessary weight to your projects.

Good Workability: Easy to process, bend, and shape for various uses.

Comparison Between 3005 Aluminum Wire and 3003 Aluminum Wire

3005 Aluminum Wire offers higher strength and better corrosion resistance, making it more suitable for structural and heavy-duty applications.

Why Choose Us As Your 3005 Aluminum Wire Supplier?

Certified Quality: All products comply with international standards, ensuring consistent performance.

Affordable Pricing: Competitive rates for both small and bulk orders.

Wide Inventory: Ample stock to meet immediate and large-scale requirements.

Global Shipping: Fast, safe, and reliable delivery worldwide.

Expert Support: A dedicated team to assist with product selection and technical inquiries.

Huaxiao Metal has years of experience in providing high-quality aluminum products, including 3005 aluminum wire, to customers in North America, South America, and Europe. Our strong supply chain, attention to quality, and commitment to customer satisfaction make us the preferred choice for all your aluminum wire needs.

Whether you are an industrial client or a distributor, we are ready to assist you with any questions regarding 3005 aluminum wire pricing or bulk orders. Let us be your trusted partner for all aluminum wire requirements.