HXM is one of the 7050 aluminum strip suppliers and manufacturers in China and provides high-quality 7050 aluminum strips for applications with strict requirements for high strength and corrosion resistance. Our 7050 aluminum strips are in sufficient stock and complete in specifications. We can provide a variety of size options according to customer needs to ensure fast delivery. We offer competitive 7050 aluminum strip prices to ensure the high cost-effectiveness of the products.

Whether you need to purchase in large quantities or customize in small quantities, we can meet your needs. Please feel free to contact us for consultation and purchase.

7050 Aluminium Strip Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

7050 Aluminum Strip Data Sheet

Equivalent Grades Of Aluminum 7050 Strip

| Standard | 7050 Aluminum | Equivalent Grades | Notes |

|---|---|---|---|

| Aluminum Association (AA) | 7050 | – | Standard aluminum alloy designation |

| International Organization for Standardization (ISO) | 7050 | 3.4164 | Comparable performance to 7050 |

| Deutsches Institut für Normung (DIN) | – | EN AW-7050 | Standard corresponding designation |

| British Standards (BS) | – | 7075-T6 | 7075-T6 is often used interchangeably with 7050 in UK standards |

| Japanese Industrial Standards (JIS) | – | A7075-T6 | A7075-T6 is similar to 7050 under JIS standards |

| Chinese National Standards (GB) | – | 7075-T6 | 7075-T6 is commonly used as an equivalent in China |

Chemical Composition of 7050 Aluminum Strip

Below is a typical chemical composition for 7050 aluminum strip:

| Element | Chemical Composition (%) |

|---|---|

| Al | Balance (approximately 90.7 – 94.7%) |

| Zn | 5.7 – 6.7% |

| Cu | 2.0 – 2.6% |

| Mg | 2.2 – 2.8% |

| Mn | 0.1 – 0.3% |

| Cr | 0.04 – 0.35% |

| Si | 0.1% max |

| Fe | 0.2% max |

| Ti | 0.05 – 0.15% |

| Other Elements | Each 0.05% max, Total 0.15% max |

Mechanical Properties and Tempers of 7050 Aluminium Strip

| Property | 7050-T6 | 7050-T7451 | 7050-T651 | 7050-T76 |

|---|---|---|---|---|

| Yield Strength (MPa) | 503 – 572 | 483 – 540 | 483 – 552 | 483 – 552 |

| Ultimate Tensile Strength (MPa) | 572 – 641 | 552 – 620 | 552 – 621 | 552 – 621 |

| Elongation (%) | 8 – 10 | 10 – 12 | 10 – 12 | 10 – 12 |

| Shear Strength (MPa) | 431 – 517 | 414 – 482 | 414 – 482 | 414 – 482 |

| Hardness (Brinell) | 150 – 180 | 145 – 175 | 145 – 175 | 145 – 175 |

For high-quality 7050 aluminum strip and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7050 Aluminum Strips Metal

7050 aluminum alloy is a high-strength aluminum alloy widely used in aerospace and other applications requiring high strength and corrosion resistance. 7050 aluminum strip can have a variety of different states according to its heat treatment process, and each state has its specific performance and applicable scenarios. The following are several common states (Tempers) of 7050 aluminum strip and their characteristics:

7050-T6

Features: the 7050-T6 state is the most commonly used heat treatment state in 7050 aluminum alloy. After T6 treatment, the 7050 aluminum strip has excellent strength, hardness, and corrosion resistance after dissolution treatment and artificial aging.

Application: Mainly used in structural parts, aircraft wings, and fuselage parts in the aerospace field.

7050-T7451

Features: The 7050-T7451 state has a higher resistance to stress corrosion cracking than the T6 state. Through a special heat treatment process and stabilization treatment, the T7451 state provides better comprehensive performance, especially tolerance to the environment.

Application: Suitable for applications with higher requirements for stress corrosion cracking resistance, such as aircraft structural parts and high-load components.

7050-T651

Features: The 7050-T651 state is a modified version of the T6 state with higher processability. By performing tensile stress release treatment after heat treatment, the internal stress is reduced, thereby improving the mechanical properties and processing performance.

Application: Widely used in aluminum alloy parts with complex structures, such as aircraft fuselage structural parts.

7050-T76

Features: The 7050-T76 state is an aged state that provides good mechanical properties and higher stress corrosion resistance. It is mainly solution treated and naturally aged to provide balanced performance characteristics.

Application: Suitable for structural parts and aviation components that require higher corrosion resistance and stability.

Applications of 7050 Aluminum Strip Metal

Aerospace: 7050 is widely used in the aerospace industry for structural components, including aircraft wings and fuselage parts, due to its high strength and fatigue resistance.

Military: It is used in military applications for parts that require high strength and durability under stress.

Automotive: Used in high-performance automotive components where strength and lightweight properties are important.

Marine: It can be used in marine environments where moderate corrosion resistance is acceptable and high strength is necessary.

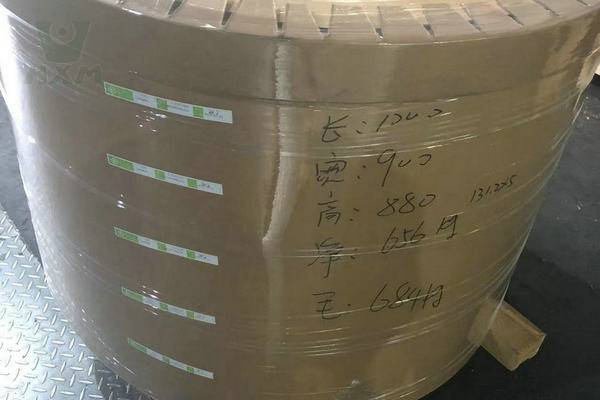

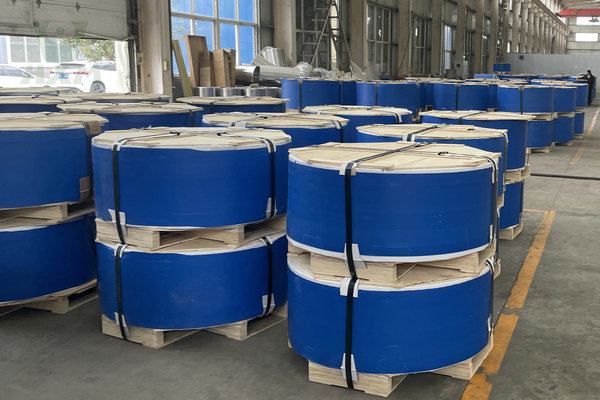

7050 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 7050 Aluminum Strip?

7050 aluminum strip is a type of flat, thin aluminum sheet made from the 7050 alloy, which is known for its high strength, excellent fatigue resistance, and good corrosion resistance. The 7050 alloy belongs to the 7000 series of aluminum alloys, which are primarily alloyed with zinc, and sometimes contain other elements like magnesium and copper.

7000 Series Aluminum

7050 Aluminum Strip Compare To Other Aluminum Strip

1. 7050 vs. 6061 Aluminum Strip

Strength: 7050 is stronger than 6061, making it more suitable for high-strength applications where load-bearing capacity is critical.

Fatigue Resistance: 7050 excels in fatigue resistance, which is important for applications that experience cyclic loading, such as aerospace structures. 6061, while strong, does not match 7050 in this respect.

Corrosion Resistance: 6061 has better general corrosion resistance compared to 7050, which is more susceptible to stress corrosion cracking.

Weldability: 6061 is more easily weldable than 7050, which can be challenging to weld and requires careful handling.

Applications: 6061 is more versatile and used in a variety of applications, including construction and automotive parts, while 7050 is specialized for aerospace and high-stress applications.

2. 7050 vs. 7075 Aluminum Strip

Strength: 7075 is often stronger than 7050, especially in its T6 heat-treated condition, making it suitable for extremely high-strength applications.

Fatigue Resistance: 7050 generally offers better fatigue resistance than 7075, making it more suitable for components that undergo repeated stress.

Corrosion Resistance: 7050 has better corrosion resistance compared to 7075, which is more prone to corrosion, particularly in humid environments.

Weldability: 7050 is generally more weldable than 7075, which is difficult to weld and prone to cracking.

Applications: 7075 is used in aerospace and military applications where extreme strength is needed, while 7050 is used where a balance of strength and fatigue resistance is crucial.

3. 7050 vs. 2024 Aluminum Strip

Strength: Both 7050 and 2024 are high-strength alloys, but 2024 can have superior tensile strength and fatigue resistance in certain conditions.

Fatigue Resistance: 2024 has excellent fatigue resistance, but 7050 is specifically designed for better fatigue performance under cyclic loading.

Corrosion Resistance: 7050 offers better corrosion resistance compared to 2024, which is more susceptible to corrosion and often requires protective coatings.

Weldability: 7050 is more weldable than 2024, which is challenging to weld and can suffer from stress corrosion cracking.

Applications: 2024 is widely used in aerospace applications where high strength and fatigue resistance are critical, but 7050 is chosen when improved corrosion resistance is needed alongside high strength.

4. 7050 vs. 5052 Aluminum Strip

Strength: 7050 is significantly stronger than 5052, making it suitable for structural and load-bearing applications.

Corrosion Resistance: 5052 has superior corrosion resistance compared to 7050, particularly in marine and chemical environments.

Formability: 5052 is more formable and easier to work with, making it ideal for applications requiring extensive bending and shaping.

Weldability: Both alloys are weldable, but 5052 is easier to weld and more forgiving in various fabrication processes.

Applications: 5052 is used in marine environments and applications requiring high corrosion resistance and formability, while 7050 is used where high strength and fatigue resistance are more critical.

Characteristics of 7050 Aluminum Strip

High Strength: The 7050 aluminum strip is known for its superior strength compared to many other aluminum alloys. It is often used in applications where structural strength and load-bearing capacity are critical.

Fatigue Resistance: One of the standout properties of 7050 is its excellent fatigue resistance, which makes it ideal for applications that experience cyclic loading or repeated stress.

Corrosion Resistance: While not as corrosion-resistant as alloys like 5052, 7050 still offers good resistance to corrosion, especially when used in treated or coated forms. It performs well in environments that are not excessively harsh.

Weldability: 7050 aluminum is somewhat less weldable compared to other high-strength aluminum alloys like 6061. It requires careful welding techniques and is often used in applications where welding is minimal or where pre-weld heat treatment is applied.

Heat Treatability: 7050 aluminum can be heat-treated to enhance its mechanical properties, including strength and hardness. This makes it suitable for applications where precise control of material properties is required.

Machinability: It has good machinability, allowing for the creation of detailed and complex parts with high precision.

How Can I Get A Sample Of 7050 Aluminum Strips?

Yes, we can provide samples of 7050 aluminum strips for your testing. We can also provide samples of other materials. If you are unsure whether 7050 or other materials of aluminum strips meet your project requirements, you can contact us to get a sample.

Why Choose Us As Your 7050 Aluminum Strip Supplier?

If you are looking for a manufacturer and exporter of 7050 Aluminum Strips, I think we can be one of your Aluminum Strip Suppliers! Here are some reasons why we think you can choose us:

Industry Time: We have been engaged in the metal industry for more than 10 years, with a professional manufacturing and export service team, advanced machinery and equipment, etc.

Competitive Product Prices: Due to our long history in this industry, we have long-term cooperation projects with many steel mills, so the quality and price of our products can be guaranteed. Our internal manufacturing efficiency has been improved, and we can produce more and better aluminum products in the same amount of time, thereby reducing our cost prices.

Excellent Customer Service: For first-time customers, we provide videos and on-site factory visits to increase customer trust. We accept payment methods such as TT, L/C, etc. The product warranty period is 5 years, etc.

Why not give us a chance to serve your project? I believe we can become one of your best and most trusted aluminum strip suppliers!