7005 aluminum strip is a high-strength aluminum alloy material, widely used in engineering projects that require light weight and high strength. As a professional 7005 aluminum strip supplier, we provide 7005 aluminum strips in various specifications and sizes, with sufficient inventory and timely delivery. We always adhere to providing customers with high-quality products at reasonable prices to ensure that the needs of different projects are met.

Whether it is a large-scale industrial purchase or a small-volume custom order, we can provide flexible services and support. Welcome to contact us for more information and quotes on the 7005 aluminum strip.

7005 Aluminium Strip Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

7005 Aluminum Strip Data Sheet

Equivalent Grades Of Aluminum 7005 Strip

| Standard | Equivalent Grade | Description |

|---|---|---|

| International Standards | ||

| DIN | DIN 3.4365 | Similar properties but not a direct match |

| BS | BS L109 | Close equivalent in terms of properties |

| AFNOR | AFNOR 7020 T6 | 7020 alloy, though different, shares some characteristics with 7005 |

| U.S. Military Standards | ||

| MIL-DTL-5005 | MIL-DTL-5005 | Includes several alloys similar to 7005, used in military and aerospace applications |

| Chinese Standards | ||

| GB/T 3190-2008 | GB/T 3190-2008 | Includes equivalent grades for 7000 series alloys; specific equivalents may vary |

| Japanese Standards | ||

| JIS | JIS A7075 | Not a direct equivalent but similar in strength and applications |

| International Standards | ||

| ISO | ISO 209 | General specification for aluminum and its alloys; specific equivalents may be found based on alloy composition and mechanical properties |

Chemical Composition of 7005 Aluminum Strip

| Element | Typical Range (%) |

|---|---|

| Al | 90.7 – 94.7 |

| Zn | 4.2 – 4.7 |

| Mg | 1.2 – 1.8 |

| Cu | 0.7 – 1.0 |

| Mn | 0.3 – 0.6 |

| Cr | 0.18 – 0.28 |

| Si | 0.10 – 0.25 |

| Fe | 0.15 – 0.40 |

| Ti | 0.05 – 0.15 |

| Other Elements | Each ≤ 0.05 |

Mechanical Properties and Tempers of 7005 Aluminium Strip

| Temper | Ultimate Tensile Strength (UTS) | Yield Strength (YS) | Elongation | Hardness (HB) | Description |

|---|---|---|---|---|---|

| T6 | ~310 – 450 MPa (45 – 65 ksi) | ~250 – 380 MPa (36 – 55 ksi) | 8% – 12% | 85 – 95 HB | High strength and fatigue resistance, heat-treated for maximum hardness. |

| T651 | ~310 – 450 MPa (45 – 65 ksi) | ~250 – 380 MPa (36 – 55 ksi) | 8% – 12% | 85 – 95 HB | Similar to T6, but relieved by stretching for improved dimensional stability. |

| T73 | ~310 – 450 MPa (45 – 65 ksi) | ~250 – 380 MPa (36 – 55 ksi) | 8% – 12% | 85 – 95 HB | Good strength with enhanced resistance to stress-corrosion cracking, aged to stable condition. |

| T74 | ~310 – 450 MPa (45 – 65 ksi) | ~250 – 380 MPa (36 – 55 ksi) | 8% – 12% | 85 – 95 HB | Aged to a specific strength level for precise performance requirements. |

| O | ~150 – 250 MPa (22 – 36 ksi) | ~80 – 150 MPa (11 – 22 ksi) | 15% – 20% | 60 – 80 HB | Fully annealed with lower strength, offering enhanced formability and ductility. |

For high-quality 7005 aluminum strip and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7005 Aluminum Strips Metal

-

Strain-Hardened (H12, H14, H16, H18): These tempers involve increasing hardness through cold working. The numbers indicate the degree of strain hardening, with H18 being the hardest.

-

Strain-Hardened and Partially Annealed (H22, H24, H26, H28): These tempers involve a combination of strain hardening and partial annealing to improve formability while retaining some hardness.

-

Strain-Hardened and Stabilized (H32, H34, H36, H38): These tempers provide stability in mechanical properties, combining strain hardening with stabilization treatments to enhance strength and durability.

The 7005 aluminum alloy is known for its strength and is commonly used in applications requiring high strength-to-weight ratios. Different tempers of 7005 aluminum strips metal offer varying properties suited to specific applications. Here’s a breakdown of some common tempers for 7005 aluminum strips:

1. 7005-T6

- Properties: This is one of the most common tempers for 7005 aluminum, offering high strength and good fatigue resistance. It is heat-treated to achieve maximum strength and hardness.

- Applications: Ideal for structural applications, aerospace components, and high-stress components like bicycle frames and aircraft structures.

2. 7005-T651

- Properties: This temper is similar to T6 but includes an additional step of stretching to relieve internal stresses, resulting in improved dimensional stability and reduced warping.

- Applications: Used in applications where high strength and good dimensional stability are required, such as in precision aerospace and automotive parts.

3. 7005-T73

- Properties: Offers good strength and excellent resistance to stress-corrosion cracking. It is aged to a stable condition for improved performance in harsh environments.

- Applications: Often used in aerospace applications where resistance to stress corrosion is critical, such as aircraft fuselage and wing structures.

4. 7005-O (Annealed)

- Properties: This temper is fully annealed, meaning it has been heat-treated to a soft, workable state with reduced strength compared to T6 or T651. It provides good formability and ductility.

- Applications: Suitable for applications where ease of machining and forming is more important than high strength, such as in the manufacturing of complex shapes or components that will undergo further processing.

5. 7005-T74

- Properties: Similar to T73 but aged to a specific strength level to enhance performance in specific conditions.

- Applications: Used in high-strength applications requiring precise strength properties, such as in aerospace and high-performance sporting equipment.

Applications of 7005 Aluminum Strip Metal

Bicycle Frames: 7005 aluminum is widely used in the manufacturing of high-performance bicycle frames due to its combination of strength and lightweight properties.

Aerospace Components: The material’s high strength-to-weight ratio makes it suitable for certain aerospace parts where both durability and weight savings are critical.

Automotive Parts: Used in automotive components where strength and reduced weight are important for improving fuel efficiency and performance.

Structural Applications: Employed in construction and architectural projects that require strong yet lightweight materials.

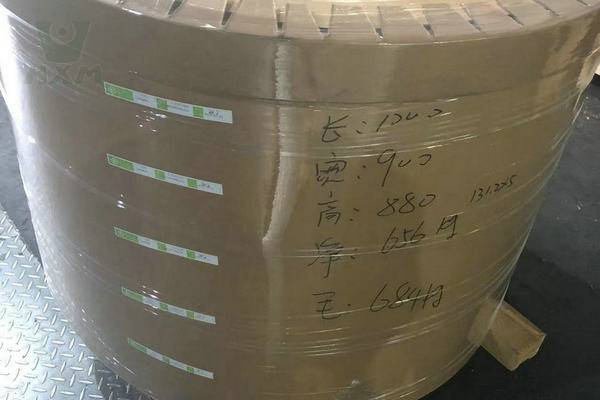

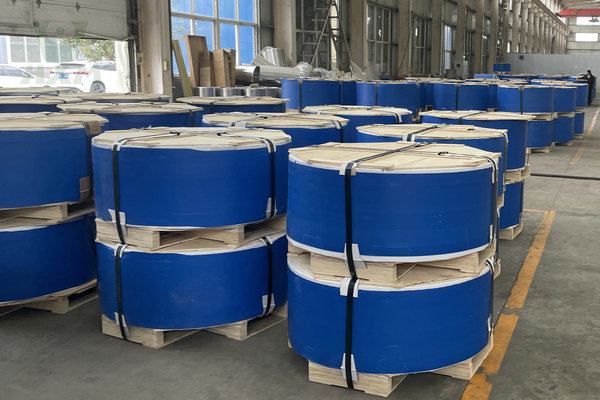

7005 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 7005 Aluminum Strip?

7005 aluminum strip is a flat, thin piece of aluminum made from the 7005 alloy, which is known for its high strength, excellent toughness, and good corrosion resistance. The 7005 alloy is part of the 7000 series aluminum alloys, which are primarily alloyed with zinc, and sometimes contain small amounts of magnesium, copper, and chromium.

7000 Series Aluminum

7005 Aluminum Strip Compare To Other Aluminum Strip

1. 7005 vs. 6061 Aluminum Strip

Strength: The 7005 aluminum strip is stronger than 6061, making it better suited for applications requiring higher strength and durability, such as structural components and bicycle frames.

Corrosion Resistance: 6061 generally offers better corrosion resistance, especially in environments where exposure to moisture or chemicals is a concern.

Weldability: Both 7005 and 6061 are weldable, but 6061 is easier to weld and less prone to post-weld cracking, making it more suitable for applications involving extensive welding.

Applications: 7005 is preferred in high-strength applications like aerospace and performance sports equipment, while 6061 is used in a broader range of applications, including construction, automotive, and general fabrication.

2. 7005 vs. 7075 Aluminum Strip

Strength: 7075 is one of the strongest aluminum alloys available, even stronger than 7005, making it ideal for highly stressed components like aerospace parts and high-performance machinery.

Corrosion Resistance: 7005 has better corrosion resistance compared to 7075, which is more susceptible to environmental corrosion, especially in humid or marine environments.

Weldability: 7005 is more weldable than 7075, which tends to crack or lose strength when welded.

Applications: 7075 is used where extreme strength is required, such as in military and aerospace applications, whereas 7005 is used in applications that balance high strength with better weldability and corrosion resistance, like bicycle frames.

3. 7005 vs. 5052 Aluminum Strip

Strength: 7005 is significantly stronger than 5052, making it more suitable for structural and high-load applications.

Corrosion Resistance: 5052 has excellent corrosion resistance, particularly in marine environments, outperforming 7005 in this aspect.

Formability: 5052 is much more formable than 7005, making it easier to bend and shape, which is useful in applications like marine hardware and chemical containers.

Applications: 5052 is used in applications where corrosion resistance and formability are key, such as in marine environments, while 7005 is chosen for its strength in structural and load-bearing applications.

4. 7005 vs. 2024 Aluminum Strip

Strength: Both 7005 and 2024 are high-strength alloys, but 2024 typically has higher fatigue resistance, making it better for cyclic loading applications.

Corrosion Resistance: 7005 has better corrosion resistance than 2024, which is more prone to corrosion, particularly in humid or marine environments.

Weldability: 7005 is more weldable than 2024, which is difficult to weld and can suffer from stress corrosion cracking.

Applications: 2024 is commonly used in aerospace structures where fatigue resistance is critical, while 7005 is used in applications requiring a balance of strength, weldability, and corrosion resistance, such as bicycle frames and other structural components.

Characteristics of 7005 Aluminum Strip

- High Strength: 7005 aluminum strip is known for its high tensile strength, making it suitable for structural applications where durability and load-bearing capacity are essential.

Good Corrosion Resistance: Although not as corrosion-resistant as some other aluminum alloys like 6061, 7005 aluminum still offers good resistance to corrosion, particularly when treated with a protective coating or anodizing.

Weldability: Unlike some other high-strength aluminum alloys in the 7000 series, 7005 can be welded without losing too much of its strength, making it a good choice for applications that require welded joints.

Heat Treatability: 7005 aluminum is heat-treatable, which allows for further enhancement of its mechanical properties, such as strength and hardness, through processes like aging and quenching.

Lightweight: Despite its high strength, 7005 aluminum strip is lightweight, making it ideal for applications where minimizing weight is crucial, such as in transportation and sports equipment.

How Can I Get A Sample Of 7005 Aluminum Strips?

Yes, we can provide samples of 7005 aluminum strips for your testing. We can also provide samples of other materials. If you are unsure whether 7005 or other materials of aluminum strips meet your project requirements, you can contact us to get a sample.

Why Choose Us As Your 7005 Aluminum Strip Supplier?

If you are looking for a manufacturer and exporter of 7005 Aluminum Strips, I think we can be one of your Aluminum Strip Suppliers! Here are some reasons why we think you can choose us:

Industry Time: We have been engaged in the metal industry for more than 10 years, with a professional manufacturing and export service team, advanced machinery and equipment, etc.

Competitive Product Prices: Due to our long history in this industry, we have long-term cooperation projects with many steel mills, so the quality and price of our products can be guaranteed. Our internal manufacturing efficiency has been improved, and we can produce more and better aluminum products in the same amount of time, thereby reducing our cost prices.

Excellent Customer Service: For first-time customers, we provide videos and on-site factory visits to increase customer trust. We accept payment methods such as TT, L/C, etc. The product warranty period is 5 years, etc.

Why not give us a chance to serve your project? I believe we can become one of your best and most trusted aluminum strip suppliers!