Huaxiao Metal – Your Trusted Global 6061 Aluminum Strip Supplier and Manufacturer

Looking for high-quality 6061 Aluminum Strip at an affordable price? Huaxiao Metal is one of the leading 6061 Aluminum Strip manufacturers and suppliers in China, offering a wide range of thicknesses and widths, fast delivery, and custom specifications. Providing high-quality 6061 Aluminum Strip for a variety of industrial applications. Our 6061 aluminum is in sufficient stock with a full range of specifications and can be delivered quickly according to your needs.

We offer competitive 6061 Aluminum Strip prices to ensure you get the best value on your purchase. Whether you need to order in large quantities or purchase in small quantities, our 6061 Aluminum Strip can meet your needs. Welcome to contact us for consultation and purchase of 6061 Aluminum Strip.

6061 Aluminium Strip Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

6061 Aluminum Strip Data Sheet

Chemical Composition of 6061 Aluminum Strip

| Elements | Mg | Fe | Cu | Mn | Si | Cr | Ti | Zn | Others | Al |

| Content | 0.8-1.2 | 0.70 | 0.15-0.40 | 0.15 | 0.40-0.8 | 0.04-0.35 | 0.15 | 0.25 | 0.05 | Remains |

Mechanical Properties and Tempers of 6061 Aluminium Strip

| Typical Mechanical Properties of 6061 Aluminium Strip | |||

| Temper | Tensile Strength | Yield Strength | Elongation |

| KSI | KSI | % | |

| T451 | 35 | 21 | 25 |

| T651 | 45 | 40 | 17 |

At Huaxiao Metal, we offer 6061 aluminum strips in various tempers, such as O, T4, T6, and T651, allowing customers to select the appropriate mechanical properties for their specific needs.

Different Tempers of 6061 Aluminum Strips Metal

6061 aluminum alloy is a commonly used aluminum alloy that can be used to manufacture a variety of products, including sheet metal products. It can be processed in different states to obtain different mechanical properties and uses. The following are several common states of 6061 aluminum strip metal:

T6: This is one of the most common states in 6061 aluminum strip metal. In the T6 state, the aluminum alloy undergoes high-temperature solution treatment and then is rapidly quenched. This process gives it high strength and hardness. 6061 aluminum in T6 temper is commonly used in structural applications where strength is critical.

T4: In this state, the aluminum alloy has been solid solution treated and then aged naturally. It offers good formability and weldability while still possessing reasonable strength. 6061 aluminum in T4 temper is typically used in applications that require forming or bending.

T651 : Similar to the T6 condition, but with additional stretching after solution treatment. This stretching process reduces internal stress and enhances dimensional stability. 6061 aluminum in T651 condition is typically used in applications requiring precision parts and components where tight tolerances are required.

O : This is the annealed state of 6061 aluminum, completely softened. It has excellent formability but is less strong than in the processed state. 6061 aluminum in the O temper is suitable for applications where extensive forming is required or where strength is not a primary consideration.

T6511: This is a stretched version of the T651 condition, achieved through a stretching process. It offers properties similar to T651 aluminum, but with improved flatness and straightness. 6061 aluminum in the T6511 temper is typically used in applications where flatness is critical, such as aerospace components.

These are some of the most common states of 6061 aluminum strips, but there are others available, each offering specific properties suitable for different applications.

Applications of 6061 Aluminum Strip Metal

6061 aluminum strip metal is widely used across various industries due to its excellent mechanical properties, corrosion resistance, and versatility. Here are some common applications:

Automotive Industry: 6061 aluminum strips are used in the manufacturing of automotive parts such as radiators, heat exchangers, and body panels. Their lightweight nature helps improve fuel efficiency while maintaining strength and durability.

Aerospace Industry: In aerospace, 6061 aluminum is used for making aircraft components like wings, fuselage structures, and landing gear parts, where a balance of strength and weight is crucial.

Construction: Due to its strength and corrosion resistance, 6061 aluminum strips are used in building structures, roofing, and exterior facades. They are also used in the construction of bridges, walkways, and scaffolding.

Marine Industry: 6061 aluminum is highly resistant to seawater corrosion, making it ideal for marine applications such as shipbuilding, boat hulls, and other marine structures.

Electronics: The material is used in the production of heat sinks, electronic casings, and other components where efficient heat dissipation and lightweight are important.

Furniture and Fixtures: 6061 aluminum strips are used in making durable and lightweight furniture, as well as fixtures and fittings for both commercial and residential use.

Machinery and Equipment: 6061 aluminum strips are used in various machinery and equipment parts, including hydraulic systems, pneumatic tools, and frames for industrial machines due to their high strength-to-weight ratio.

Sports Equipment: The material’s lightweight and durable properties make it a popular choice for manufacturing sports equipment like bicycle frames, golf clubs, and camping gear.

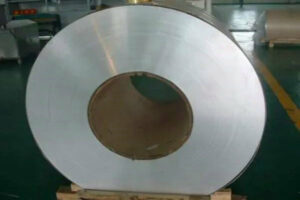

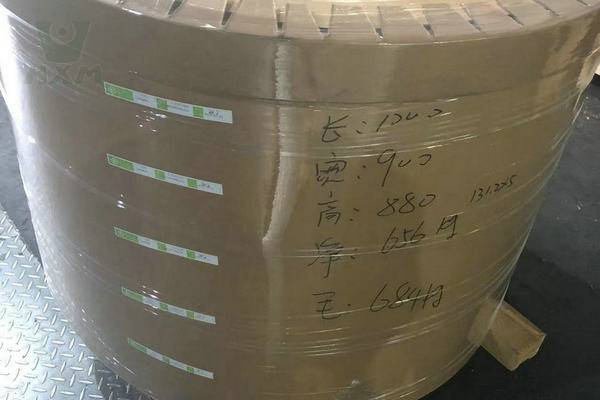

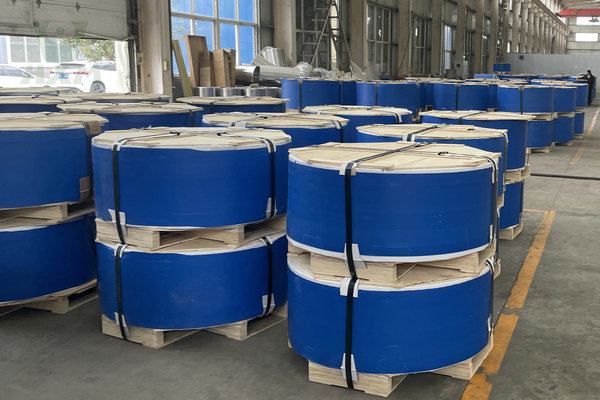

6061 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

Contact Huaxiao Metal immediately to learn more about the price, stock, and specifications of the 6061 aluminum strip! Our sales team is always ready to provide you with professional consultation and quotation services.

FAQ

What Is 6061 Aluminum Strip?

6061 aluminum strip is a flat, thin piece of aluminum made from the 6061 alloy. It is a widely used aluminum grade known for its excellent mechanical properties, including good strength, corrosion resistance, and machinability. The 6061 alloy is primarily aluminum, with magnesium and silicon as its major alloying elements. This combination gives it a good balance of properties, making it versatile and suitable for various applications.

The 6061 aluminum strip is often used in industries where both structural strength and lightweight materials are essential. It can be easily formed, welded, and machined, making it suitable for a wide range of fabrication processes. The strip form is handy in applications where the material needs to be cut into precise shapes, bent, or layered.

6000 Series Aluminum

6061 Aluminum Strip Compare To Other Aluminum Strip

1. 6061 vs. 5052 Aluminum Strip

Strength: 6061 is stronger than 5052, making it better suited for structural applications where higher strength is required.

Corrosion Resistance: 5052 offers better corrosion resistance, particularly in marine environments, due to its higher magnesium content.

Formability: 5052 is more easily formed and bent than 6061, which can crack if bent too sharply without proper treatment.

Weldability: Both alloys are weldable, but 5052 is generally easier to weld and more forgiving, especially in thinner gauges.

2. 6061 vs. 7075 Aluminum Strip

Strength: 7075 is significantly stronger than 6061, making it suitable for high-stress applications, especially in aerospace.

Corrosion Resistance: 6061 has better corrosion resistance compared to 7075, which is more prone to corrosion, especially in humid environments.

Machinability: Both alloys are machinable, but 7075 is often preferred when machining parts require very high strength.

Cost: 7075 is generally more expensive due to its higher strength and specialized applications.

3. 6061 vs. 3003 Aluminum Strip

Strength: 6061 is much stronger than 3003, which is a non-heat-treatable alloy with moderate strength.

Corrosion Resistance: 3003 has good corrosion resistance, especially to atmospheric conditions, but 6061 is better in certain corrosive environments.

Formability: 3003 is more formable than 6061, making it easier to work with in applications requiring extensive shaping or bending.

Applications: 3003 is often used in applications requiring good corrosion resistance and formability, such as in cooking utensils, while 6061 is used where strength and machinability are more critical.

4. 6061 vs. 2024 Aluminum Strip

Strength: 2024 is stronger than 6061, particularly in its heat-treated condition, making it a preferred choice for aerospace structures.

Corrosion Resistance: 6061 offers better corrosion resistance than 2024, which tends to corrode more easily in certain environments.

Weldability: 6061 is more weldable than 2024, which can crack or weaken when welded.

Fatigue Resistance: 2024 has better fatigue resistance, which is important for cyclic loading conditions found in aircraft structures.

Characteristics of 6061 Aluminum Strip

Strength: It has good tensile strength, making it suitable for structural applications.

Corrosion Resistance: The 6061 alloy has good corrosion resistance, particularly in environments where moisture or chemicals are present.

Machinability: It can be easily machined into various shapes and sizes without compromising its structural integrity.

Weldability: 6061 aluminum can be readily welded, which is advantageous for fabrication processes.

Heat Treatability: The alloy can be heat-treated to enhance its strength and other mechanical properties.

How Can I Get A Sample Of 6061 Aluminum Strips?

Yes, we can provide samples of 6061 aluminum strips for your testing. We can also provide samples of other materials. If you are unsure whether 6061 or other materials of aluminum strips meet your project requirements, you can contact us to get a sample.

Why Choose Us As Your 6061 Aluminum Strip Supplier?

If you are looking for a manufacturer and exporter of 6061 Aluminum Strips, I think we can be one of your Aluminum Strip Suppliers! Here are some reasons why we think you can choose us:

Industry Time: We have been engaged in the metal industry for more than 10 years, with a professional manufacturing and export service team, advanced machinery and equipment, etc.

Competitive Product Prices: Due to our long history in this industry, we have long-term cooperation projects with many steel mills, so the quality and price of our products can be guaranteed. Our internal manufacturing efficiency has been improved, and we can produce more and better aluminum products in the same amount of time, thereby reducing our cost prices.

Excellent Customer Service: For first-time customers, we provide videos and on-site factory visits to increase customer trust. We accept payment methods such as TT, L/C, etc. The product warranty period is 5 years, etc.

Why not give us a chance to serve your project? I believe we can become one of your best and most trusted aluminum strip suppliers!

Huaxiao Metal is more than just a 6061 aluminum strip manufacturer. We are your long-term partner in high-performance aluminum procurement. Whether you need regular stock sizes or complex custom orders, we will serve you wholeheartedly.

Contact us today for more information, free samples, or a personalized quote. Let’s work together to create brilliance with reliable aluminum solutions.