5052 Aluminum Strip Suppliers and Manufacturers in China

As one of the professional 5052 aluminum strip suppliers and manufacturers in China, we provide domestic customers with high-quality and stable aluminum metal products. 5052 aluminum strip is widely used in aviation, shipbuilding, construction, and other fields due to its excellent corrosion resistance and good formability. We have sufficient inventory to quickly meet your procurement needs while ensuring that the product quality meets strict industry standards.

Feel free to consult us for the latest inventory and quotation information, and look forward to becoming one of your aluminum strip suppliers!

5052 Aluminium Strip Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H32, H34, H36, H38, H111, H112, etc.

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

5052 Aluminum Strip Data Sheet

Equivalent Grades Of 5052 Aluminum Strip

Here’s a concise table showing the equivalent grades and standards for 5052 aluminum strips:

| Standard/Grade | Equivalent Grade | Key Features | Applications |

|---|---|---|---|

| 5052 (US Standard) | 5052 | Excellent corrosion resistance, good strength, and workability | Marine, automotive, construction |

| EN AW-5052 (European Standard) | EN AW-5052 | Same properties as 5052 | Same as 5052 |

| JIS A5052 (Japanese Standard) | JIS A5052 | Same properties as 5052 | Same as 5052 |

| GB 5052 (Chinese Standard) | GB 5052 | Same properties as 5052 | Same as 5052 |

Chemical Composition of 5052 Aluminum Strip

Here’s the chemical composition of the 5052 aluminum strip displayed in a horizontal table format using element symbols:

| Element | Al | Mg | Cr | Mn | Cu | Si | Fe | Zn | Other Elements |

|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | Balance | 2.2 – 2.8 | 0.15 – 0.35 | 0.10 – 0.50 | ≤ 0.10 | ≤ 0.25 | ≤ 0.40 | ≤ 0.10 | Each ≤ 0.05 |

Mechanical Properties of 5052 Aluminium Strips with Different Tempers

Temper | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

5052-O (Annealed) | 65 – 115 | 130 – 185 | 25 – 40 | 30 – 50 |

5052-H32 | 210 – 250 | 260 – 300 | 12 – 20 | 60 – 80 |

5052-H34 | 230 – 260 | 270 – 310 | 10 – 18 | 65 – 85 |

5052-H36 | 240 – 270 | 280 – 320 | 8 – 16 | 70 – 90 |

5052-H38 | 250 – 280 | 290 – 330 | 6 – 14 | 75 – 95 |

For high-quality 5052 aluminum strips and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 5052 Aluminum Strips Metal

| Temper | Properties | Applications |

|---|---|---|

| O | Softest form with maximum ductility and lowest strength | Used for applications requiring high formability, such as deep drawing, bending, and complex shapes; minimal residual stress applications |

| H32 | Strain-hardened and partially annealed, offering good strength with moderate ductility | Ideal for structural applications needing a balance of strength and formability, such as pressure vessels, marine components, and fuel tanks |

| H34 | Further strain-hardened compared to H32, offering higher strength with reduced ductility | Suitable for applications requiring higher strength and less formability, such as in automotive parts, heavy-duty pressure vessels, and structures |

| H36 | Stronger than H34 with further reduced ductility | Used in high-stress applications where additional strength is needed, such as in structural components and industrial applications |

| H38 | Highest strength with the lowest ductility in the H3x series | Applied in applications requiring maximum strength with minimal formability, such as in heavy-duty structural parts and some aerospace components |

| H112 | Solution heat-treated and stabilized, providing a balance of moderate strength and good corrosion resistance | Commonly used in general-purpose applications where good strength and corrosion resistance are required, such as in marine and architectural components |

H32, H34, H36, H38, and other tempers ensure that the material can be used in different application scenarios. As a 5052 aluminum strip supplier, we have a large inventory of aluminum strips and can quickly complete customer orders. Inquire now to get the latest aluminum narrow strip prices and our inventory information!

Looking for 5052 aluminum strips in the right state? Huaxiao Metal provides a variety of tempers and sufficient inventory to meet your various application needs.

Applications of 5052 Aluminum Strip Metal

Marine Industry: Due to its excellent corrosion resistance, the 5052 aluminum strip is commonly used in marine applications such as boat hulls, decks, and other components exposed to seawater.

Automotive Industry: Used in automotive parts like fuel tanks, panels, and other components where strength and corrosion resistance are important.

Aerospace Industry: Suitable for use in certain aerospace components where durability and resistance to the elements are crucial.

Construction: Often used in architectural elements, roofing, siding, and other construction components due to its combination of strength and formability.

Pressure Vessels: Employed in the manufacture of pressure vessels and tanks that require good resistance to stress corrosion and the ability to withstand harsh environments.

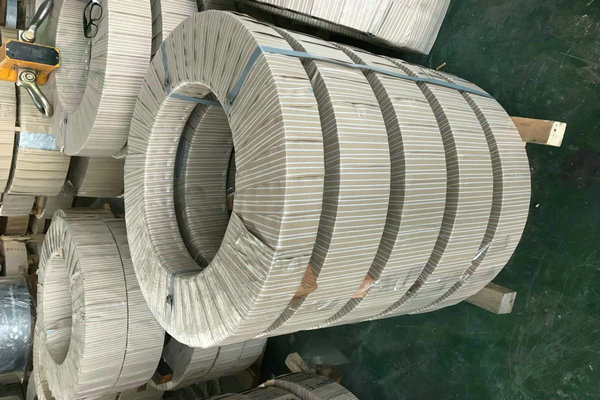

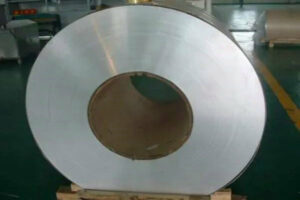

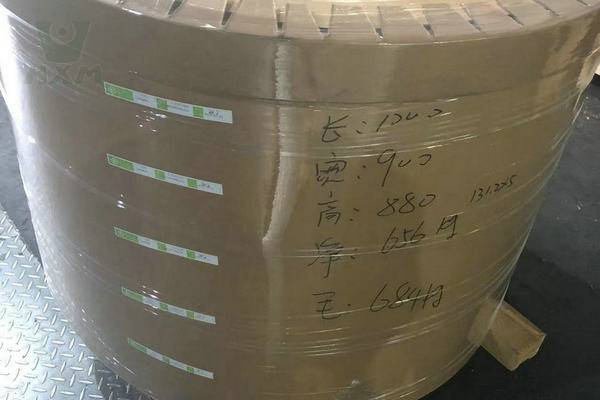

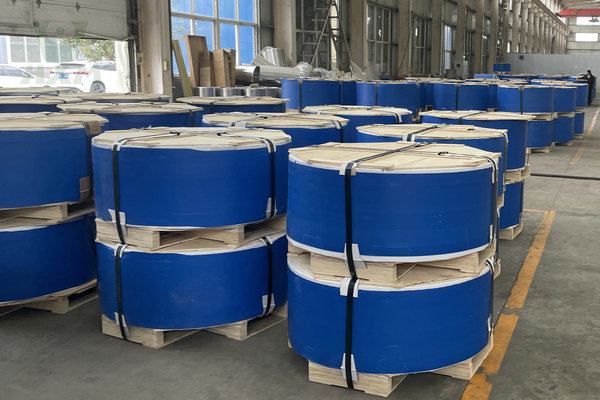

5052 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 5052 Aluminum Strip?

5052 aluminum strip is a versatile, non-heat-treatable aluminum alloy that belongs to the 5000 series, primarily known for its excellent corrosion resistance, good formability, and high strength. It is widely used in a variety of industries due to its balanced mechanical properties and durability.

5000 Series Aluminum

5052 Aluminum Strip Compare To Other Aluminum Strip

| Property | 5052 Aluminum Strip | 6061 Aluminum Strip | 5083 Aluminum Strip | 3003 Aluminum Strip |

|---|---|---|---|---|

| Composition | Contains 2.2-2.8% magnesium and 0.15-0.35% chromium | Contains 0.8-1.2% magnesium and 0.4-0.8% silicon; also contains copper and chromium | Contains 4.0-4.9% magnesium and 0.05-0.25% chromium | Contains 1.0-1.5% manganese |

| Strength | Moderate strength; stronger than 3003, but lower than 5083 and 6061 | High strength, especially after heat treatment | High strength, particularly in marine environments | Lower strength; good for applications that don’t require high strength |

| Corrosion Resistance | Excellent, especially in marine environments | Good corrosion resistance, though not as high as 5052 or 5083 | Superior corrosion resistance, especially in saltwater environments | Good corrosion resistance, but less robust than 5052 and 5083 |

| Weldability | Excellent weldability, retains corrosion resistance post-welding | Good weldability; care needed to avoid cracking | Good weldability, maintains excellent corrosion resistance | Excellent weldability, commonly used in applications where welding is required |

| Formability | Good formability, suitable for bending and complex shapes | Good formability, though less than 5052 and 3003 | Moderate formability; less than 5052, better for heavier applications | Excellent formability, highly suitable for complex shapes |

| Ductility | Good ductility, allowing it to be easily shaped | Moderate ductility, can be heat-treated for enhanced properties | Good ductility, but lower than 5052 and 3003 | Excellent ductility, highly formable for complex shapes |

| Heat Treatability | Non-heat-treatable, strength is achieved through cold working | Heat-treatable, allowing for increased strength and durability | Non-heat-treatable, like 5052, strength is achieved through cold working | Non-heat-treatable, strength is achieved through cold working |

| Applications | Marine components, automotive parts, pressure vessels, construction elements | Aerospace components, automotive parts, general engineering applications | Marine structures, pressure vessels, and other high-stress applications | Cooking utensils, chemical equipment, and general-purpose items |

How Can I Get A Sample Of 5052 Aluminum Strips?

Yes, we can provide samples of 5052 aluminum strips for your testing. We can also provide samples of other materials. If you are unsure whether 5052 or other materials of aluminum strips meet your project requirements, you can contact us to get a sample.

Why Choose Us As Your 5052 Aluminum Strip Supplier?

If you are looking for a manufacturer and exporter of 5052 Aluminum Strip, I think we can be one of your Aluminum Strip Suppliers! Here are some reasons why we think you can choose us:

Industry Time: We have been engaged in the metal industry for more than 10 years, with a professional manufacturing and export service team, advanced machinery and equipment, etc.

Competitive Product Prices: Due to our long history in this industry, we have long-term cooperation projects with many steel mills, so the quality and price of our products can be guaranteed. Our internal manufacturing efficiency has been improved, and we can produce more and better aluminum products in the same amount of time, thereby reducing our cost prices.

Excellent Customer Service: For first-time customers, we provide videos and on-site factory visits to increase customer trust. We accept payment methods such as TT, L/C, etc. The product warranty period is 5 years, etc.

Why not give us a chance to serve your project? I believe we can become one of your best and most trusted aluminum strip suppliers!