China Aluminum Honeycomb Plate Suppliers

Looking for reliable aluminum honeycomb sheet suppliers? At HXM, we are a leading aluminum honeycomb plate manufacturer offering high-quality products at competitive prices. Our extensive inventory ensures quick delivery, and we provide customized solutions to meet your specific needs. Whether you require standard sizes or bespoke dimensions, we have the capabilities to deliver. Contact us today to inquire about aluminum honeycomb sheet prices and discover how our products can enhance your project with superior strength, lightweight performance, and durability.

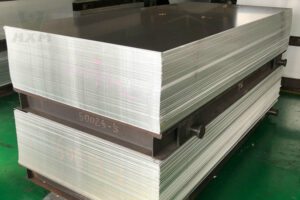

Aluminum Honeycomb Sheet Specification

- Panel thickness: 0.5mm – 3.0mm

- Core thickness: 5mm – 50mm

- Total sheet thickness: 6mm – 100mm

- Width range up to 1500mm

- Length range up to 6000mm

- Standards: GB/T 3880, ASTM B209, EN 485

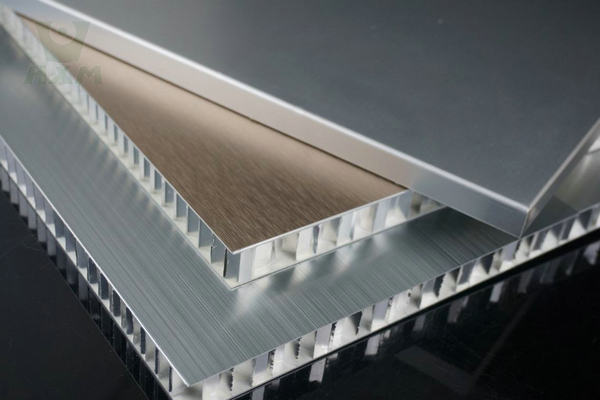

It is made of two upper and lower panels with a honeycomb in the middle. The panel is mainly made of high-quality 3003-H24 alloy aluminum plate or 5052A-H14 high manganese alloy aluminum plate as the base material. The panel thickness is 0.8-1.5mm fluorocarbon roll-coated plate or color-resistant light-painted plate. The color-resistant light-painted plate is stronger than PVDF in terms of scratch resistance, acid rain corrosion discoloration, and self-cleaning. The bottom plate thickness is 0.6-1.0mm and the total thickness is 25mm.

Aluminum honeycomb panels are a new type of environmentally friendly decorative material with lightweight, high strength, good weather resistance, flexible processing, and easy installation. Aluminum honeycomb panels have high strength and excellent load, anti-deflection, anti-bending, and wind pressure resistance. The product adopts a “honeycomb sandwich” structure, using high-strength alloy plates as the panel surface and bottom plate, and the honeycomb core is separated into numerous closed holes.

The propagation of heat and sound waves is greatly restricted. Compared with other curtain wall materials, aluminum honeycomb sheets have better thermal insulation and sound insulation performance. Since aluminum honeycomb panels are composed of thin aluminum plates and aluminum honeycomb cores, they are lighter than aluminum veneers and other metal curtain wall materials. Another feature of aluminum honeycomb sheets is that they are easy to shape and can be processed and formed into various shapes according to architectural design requirements, making architectural decoration more exquisite.

High Strength-to-Weight Ratio

Excellent Energy Absorption

Corrosion Resistance

Good Thermal Insulation

Design Flexibility

Environmental Sustainability

Fire Resistance

Ease of Fabrication and Installation

Choose us as your trusted Chinese aluminum honeycomb panel supplier. We have abundant inventory and efficient logistics to ensure that your orders, no matter how big or small, can be completed in time. Contact us now to purchase aluminum honeycomb panels to help your project go smoothly!

Are you looking for reliable aluminum honeycomb plate suppliers? At HXM, we have a comprehensive inventory of high-quality aluminum honeycomb panels ready to meet your needs. Our stock selection includes a wide range of thicknesses, cell sizes, and panel sizes, ensuring we can provide the perfect solution for your application. Whether you are in aerospace, automotive, construction, or any other industry, our aluminum honeycomb panels provide superior strength, lightweight performance, and durability.

Contact us today to check the Aluminium Honeycomb Plate stock availability and ship quickly!

Looking for a reliable China Aluminum Honeycomb Panel supplier? We specialize in producing high-quality aluminum honeycomb panels that are lightweight and durable for a variety of industries such as aerospace, construction, and transportation. Our products are carefully designed with an excellent strength-to-weight ratio, ensuring superior performance and cost-effectiveness. Partner with us to get first-class quality and competitive prices that meet your needs.

Aerospace: Aircraft interiors, satellite structures.

Automotive: Crash absorption zones, body panels.

Architecture and Construction: Wall cladding, floors, and ceilings.

Marine: Boat hulls, interior partitions.

Railway: Train interiors, crash structures.

Energy: Wind turbine blades, solar panel mounts.

Furniture: Lightweight panels, decorative panels.

Defense: Armor panels, portable structures.

Signage: Billboards, displays.

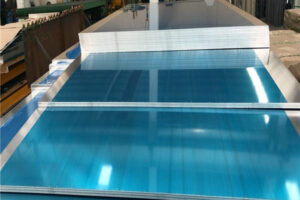

1. Material of Face Board

Both the face board and the backboard are made of 3003 series aluminum alloy. Since the alloy element of this grade is manganese, it has good forming and processing characteristics, high corrosion resistance, high compressive strength, good weldability, and conductivity, ensuring the flatness and other properties of the product.

2. Coating of Plate Surface

Adopt PCM printing pre-baking paint technology (pre-rolling) or pure polyester electrostatic powder spraying. KYNAR500 (containing more than 70% fluorocarbon resin) weather-resistant paint, which is recognized by the construction industry as having good weather resistance, can also be used as the surface coating. It has the properties of weathering resistance, corrosion resistance, UV resistance, pollution resistance, etc., and the color is bright and can keep the appearance effect as new for a long time.

3. Material of Core Board

The honeycomb core is made of 3003 series anti-corrosion aluminum alloy aluminum foil, which can be used indoors and outdoors.

4. Thickness of Composite Panel

The overall thickness of the panel is 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, and 25mm. Other specifications can be designed and manufactured as needed to meet the needs of various uses.

5. Adhesive

Two-component polyurethane adhesive is used, which can withstand high-strength pressure and shear force. After aging for 500 hours under the conditions of relative humidity of 95%~100% and temperature of 76℃ and placed for 4 days, the strength retention rate is >70%, ensuring that it will not deform or debond under extreme temperatures.

6. Sound Insulation

The structure of the metal honeycomb composite sound-absorbing panel is punching of the panel and the back panel; the back is pasted with imported SoundTex fireproof sound-absorbing paper, and the noise reduction coefficient NRC≥0.7.

FAQ

Aluminum Honeycomb Panel Weight:

The weight of aluminum honeycomb panels depends on their thickness and specifications. Generally, it is 3 to 10 kg/m2. Compared with other materials with similar strength, aluminum honeycomb panels are extremely light.

How to Cut Aluminum Honeycomb Panel?

Cutting Aluminum Honeycomb Panels:

- Use a circular saw or a router with a fine-toothed blade to make clean cuts.

- Secure the panel firmly to prevent movement during cutting.

- Apply even pressure to avoid damaging the panel’s core structure.

Note: Always wear protective gear when cutting.

How to Make Aluminum Honeycomb Panel?

Core Formation: Aluminum sheets are bonded together and expanded into a honeycomb structure.

Panel Bonding: Aluminum panels are bonded to both sides of the honeycomb core using a high-strength adhesive.

Compression and Curing: Components are compressed and cured under controlled temperature and pressure to ensure durability and precision.

As a leading aluminum honeycomb panel supplier in China, we accept customized product sizes. Whether you require standard sizes or custom designs, our advanced production technology ensures precision and consistency. Our aluminum honeycomb panels are corrosion-resistant, fire-resistant, and environmentally friendly, making them ideal for demanding applications.