China 7075 Aluminum Sheets Suppliers

As one of the leading 7075 Aluminum Sheet Suppliers in China, we are committed to providing you with high-quality 7075 aluminum sheets. 7075 aluminum sheet is known for its excellent strength and corrosion resistance and is an ideal choice for aerospace, automotive, and high-strength applications. As professional 7075 Aluminum Plate Suppliers & Manufacturers, we ensure that every piece of 7075 aluminum plate meets strict quality standards.

To learn more about 7075 Aluminum Sheet Prices, please feel free to contact us, we will provide the most competitive quotation and personalized service. Whether you need to purchase in large quantities or order in small quantities, we can meet your needs.

7075 Aluminium Sheets Specifications

Standards: ASTM, ASME, AMS, GB/T, JIS

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: O, T6, T73, T651, T7351, etc.

Delivery Time: 7-20 days.

7075 Aluminum Sheet Data Sheet

Equivalent Grades Of Aluminum 7075 Plate

| Standard | 7075 Aluminum | Equivalent Grades | Notes |

|---|---|---|---|

| Aluminum Association (AA) | 7075 | – | Standard aluminum alloy designation |

| International Organization for Standardization (ISO) | 7075 | 3.4365 | Comparable performance to 7075 |

| Deutsches Institut für Normung (DIN) | – | EN AW-7075 | Standard corresponding designation |

| British Standards (BS) | – | 7075-T6 | 7075-T6 is commonly used interchangeably |

| Japanese Industrial Standards (JIS) | – | A7075-T6 | A7075-T6 is similar under JIS standards |

| Chinese National Standards (GB) | – | 7075-T6 | 7075-T6 is often used as an equivalent |

Chemical Composition of 7075 Aluminum Sheet

| Element | Chemical Composition (%) |

|---|---|

| Al | Balance (approximately 87.1 – 91.4%) |

| Zn | 5.1 – 6.1% |

| Cu | 1.2 – 2.0% |

| Mg | 2.1 – 2.9% |

| Mn | 0.3% max |

| Cr | 0.18 – 0.28% |

| Si | 0.4% max |

| Fe | 0.5% max |

| Ti | 0.2% max |

| Other Elements | Each 0.05% max, Total 0.15% max |

Mechanical Properties and Tempers of 7075 Aluminium Sheet

| Property | 7075-T6 | 7075-T651 | 7075-T7 | 7075-T76 |

|---|---|---|---|---|

| Yield Strength (MPa) | 503 – 572 | 483 – 552 | 414 – 482 | 483 – 552 |

| Ultimate Tensile Strength (MPa) | 572 – 641 | 552 – 621 | 483 – 552 | 552 – 621 |

| Elongation (%) | 8 – 10 | 10 – 12 | 8 – 10 | 10 – 12 |

| Shear Strength (MPa) | 414 – 517 | 414 – 482 | 414 – 482 | 414 – 482 |

| Hardness (Brinell) | 150 – 180 | 145 – 175 | 150 – 180 | 145 – 175 |

For high-quality 7075 aluminum sheets and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7075 Aluminum Sheet & Plate

7075 aluminum sheet & plate is renowned for its high strength and versatility, making it suitable for various demanding applications. The properties of 7075 aluminum can vary significantly depending on its temper, which refers to the heat treatment and aging process it undergoes. Here’s a breakdown of the most common tempers for 7075 aluminum sheet & plate:

7075-T6

- Properties: This is one of the most widely used tempers for 7075 aluminum. It offers the highest strength and is known for its excellent mechanical properties. It has good resistance to stress corrosion cracking and is often used in aerospace and structural applications.

- Applications: Aircraft structures, marine components, and high-stress components.

7075-T651

- Properties: Similar to T6 but with a slightly different processing method that reduces internal stresses. It has the same high strength as T6 but with improved machinability.

- Applications: Aerospace components, high-strength structural parts, and tooling.

7075-T73

- Properties: This temper is an alternative to T6, with similar strength but enhanced stress corrosion resistance and improved toughness. It undergoes a solution heat treatment followed by aging at a lower temperature.

- Applications: Aerospace parts requiring good corrosion resistance and strength, such as fuselage frames and wing skins.

7075-T76

- Properties: This is an alternative to T73 with similar mechanical properties but offers improved resistance to localized corrosion.

- Applications: Specialized aerospace components and high-performance marine applications.

7075-O

- Properties: The ‘O’ temper denotes that the aluminum is in its soft, annealed state. This temper is not as strong as T6 but provides the maximum ductility and is easier to form and machine.

- Applications: Pre-machining or forming, and applications requiring extensive shaping.

7075-T3 and 7075-T4

- Properties: These are less commonly used but are still relevant. T3 is solution heat-treated and cold worked, offering good strength and formability. T4 is similar but requires additional aging for increased strength.

- Applications: Aerospace and military applications, where high strength and corrosion resistance are necessary.

As one of China’s leading 7075 aluminum sheet suppliers and manufacturers, Huaxiao Metal focuses on providing customers with high-performance, high-strength aluminum products. We are not only a manufacturer, but also your reliable partner.

Our 7075 aluminum sheet adopts advanced production technology and undergoes strict quality inspection to ensure that each aluminum sheet has excellent mechanical properties and corrosion resistance. Whether it is aerospace, automotive manufacturing, or high-end industrial applications, we can meet your needs. At the same time, we maintain a large inventory of aluminum sheets, which can be delivered quickly to help your project be completed quickly.

Applications of 7075 Aluminum Sheet Metal

Aerospace Industry

- Aircraft Structures: Used in the construction of aircraft fuselages, wings, and structural components due to its high strength and excellent fatigue resistance.

- Spacecraft Components: Employed in satellites and rockets, capable of withstanding extreme environments and high loads.

Military and Defense

- Armor Vehicles: Utilized in armored vehicles and protective equipment for its strength and impact resistance, protecting personnel and equipment.

- Weapon Systems: Applied in the manufacturing of high-performance weapon systems that require robust materials.

High-Performance Sports Equipment

- Bicycle Frames: Used in high-performance bicycles for frames and rims, benefiting from its high strength-to-weight ratio which enhances performance.

- Sporting Goods: Incorporated into sports equipment such as golf clubs and tennis rackets where strength and lightweight properties are crucial.

Automotive Industry

- High-Performance Vehicle Parts: Applied in racing and high-performance cars for parts like chassis, suspension systems, and structural components to enhance strength and performance.

Marine Industry

- Hull and Structural Components: Utilized in the construction of boat hulls, decks, and other marine equipment, thanks to its corrosion resistance and strength suitable for harsh marine environments.

Industrial Applications

- Structural Supports: Used in various structural supports and frameworks providing strength and stability.

- Machinery Components: Employed in manufacturing machinery parts such as gears, bearing housings, and connectors that require high strength and durability.

Transportation

- Rail Vehicles: Applied in the manufacturing of railway carriages and components, improving strength and efficiency of transportation.

- Automotive Parts: Particularly in parts requiring high strength and durability.

Aerospace Models and DIY Projects

- Models and Engineering Projects: Due to its machinability and strength, 7075 aluminum plate is also used in making aerospace models and other DIY engineering projects.

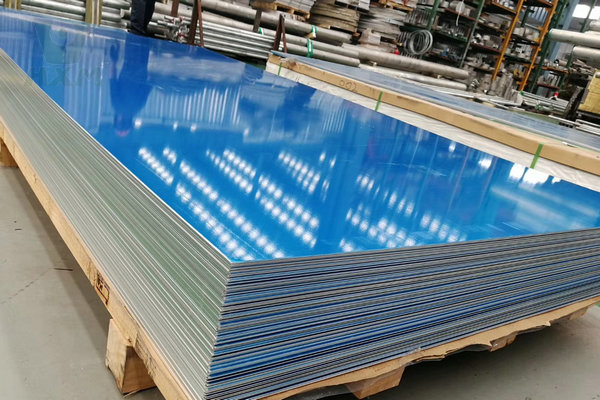

7075 Aluminum Sheet Packages

The following is our company’s conventional export packaging for aluminum plates. If you have special packaging requirements, our company can meet them. We very much hope to become one of your aluminum plate suppliers!

At Huaxiao Metal, we are committed to providing customers with cost-effective 7075 aluminum plates. As one of the well-known aluminum metal manufacturers and suppliers in China, we effectively control costs through large-scale production and efficient supply chain management and provide customers with competitive aluminum metal prices. At the same time, we have sufficient aluminum plates in stock and we can deliver them quickly. By choosing Huaxiao Metal, you can not only get high-quality aluminum plates but also enjoy a great purchasing experience. Contact us now to get an exclusive 7075 aluminum plate quote!

FAQ

What Is 7075 Aluminum Sheet?

7075 aluminum plate is a high-strength, heat-treatable aluminum alloy known for its excellent mechanical properties and durability. It is widely used in applications where strength and performance are critical, especially in the aerospace, military, and high-performance sports industries.

7075 Aluminum Plate VS Other Aluminum Plates

7075 Aluminum Plate vs. 6061 Aluminum Plate

-

Strength:

- 7075: Known for its high strength, with UTS ranging from 310 – 450 MPa (45 – 65 ksi) and YS from 250 – 380 MPa (36 – 55 ksi).

- 6061: Offers lower strength, with UTS between 240 – 310 MPa (35 – 45 ksi) and YS between 215 – 275 MPa (31 – 40 ksi).

-

Corrosion Resistance:

- 7075: Good, but not as high as 6061. Can be prone to stress-corrosion cracking in harsh environments.

- 6061: Excellent corrosion resistance, making it ideal for marine and structural applications.

-

Machinability:

- 7075: Good, but requires proper handling and tooling, especially in heat-treated states.

- 6061: Excellent machinability, easier to work with due to its more favorable properties.

-

Applications:

- 7075: Used in aerospace, military, and high-performance sports equipment due to its high strength.

- 6061: Versatile for structural components, marine environments, and automotive applications due to its good balance of properties.

7075 Aluminum Plate vs. 2024 Aluminum Plate

-

Strength:

- 7075: High strength with UTS ranging from 310 – 450 MPa (45 – 65 ksi) and YS from 250 – 380 MPa (36 – 55 ksi).

- 2024: Offers even higher strength, with UTS ranging from 470 – 550 MPa (68 – 80 ksi) and YS from 350 – 470 MPa (51 – 68 ksi).

-

Corrosion Resistance:

- 7075: Good but not exceptional. May require additional protective measures.

- 2024: Moderate corrosion resistance; typically requires coatings to protect against corrosion.

-

Machinability:

- 7075: Good, though it may be more challenging to machine in its heat-treated state.

- 2024: Also good machinability, especially when heat-treated, making it suitable for complex parts.

-

Applications:

- 7075: Ideal for aerospace and military applications where high strength is critical.

- 2024: Primarily used in aerospace applications requiring maximum strength, such as aircraft structures.

7075 Aluminum Plate vs. 7050 Aluminum Plate

-

Strength:

- 7075: Very high strength with UTS of 310 – 450 MPa (45 – 65 ksi) and YS of 250 – 380 MPa (36 – 55 ksi).

- 7050: Similar high strength, with UTS from 500 – 570 MPa (72 – 83 ksi) and YS from 430 – 485 MPa (62 – 70 ksi).

-

Corrosion Resistance:

- 7075: Good, but can be more prone to stress-corrosion cracking.

- 7050: Better stress-corrosion resistance than 7075, making it more suitable for highly demanding aerospace applications.

-

Machinability:

- 7075: Requires careful handling and appropriate tooling, particularly in heat-treated conditions.

- 7050: Similar machinability challenges as 7075, but also requires careful handling.

-

Applications:

- 7075: Used extensively in aerospace and military applications due to its strength.

- 7050: Preferred in aerospace structures where resistance to stress-corrosion cracking is crucial.

Can I Get A Sample Of 7075 Aluminum Sheets?

Yes, we can provide free samples of 7075 aluminum sheet. Please contact us directly and send the details you need.

Is 7075 Aluminum Weldable?

7075 aluminum can be welded, but it is more challenging compared to other alloys. Special welding techniques and considerations are required to avoid issues like heat-affected zone (HAZ) cracking. TIG welding is commonly used for 7075 aluminum.

Can 7075 Aluminum be Anodized?

Yes, 7075 aluminum can be anodized. Anodizing improves its corrosion resistance and provides a decorative finish. However, the anodizing process can sometimes affect the mechanical properties of the alloy.

Why Choose Us As Your 7075 Aluminum Plate Supplier?

When looking for a reliable 7075 aluminum sheet supplier or 7075 aluminum sheet for sale, you might want to consider our company. Here are some of our advantages:

1. Superior Quality Assurance

- Certified Products: Our 7075 aluminum sheets meet rigorous industry standards and specifications, ensuring you receive top-quality materials that guarantee performance and durability.

- Comprehensive Testing: Each batch of our 7075 aluminum plates undergoes extensive testing for mechanical properties, chemical composition, and surface quality to ensure they meet your exact requirements.

2. Extensive Expertise and Industry Knowledge

- Experienced Professionals: Our team possesses extensive knowledge and experience in the aluminum industry, offering expert guidance and support in selecting the right 7075 aluminum plate for your needs.

- Technical Assistance: Benefit from our technical support and advice on the application, processing, and machining of 7075 aluminum sheets to optimize performance and efficiency.

3. Competitive Pricing and Value

- Affordable Solutions: We provide 7075 aluminum plates for sale at competitive prices without compromising on quality, offering you exceptional value for your investment.

- Transparent Quotes: Receive clear and detailed quotes with no hidden fees, helping you manage your budget effectively while purchasing 7075 aluminum sheets.

4. Custom Solutions and Flexibility

- Tailored Products: We offer a wide range of sizes, tempers, and specifications for 7075 aluminum sheets, including custom options to meet your unique requirements.

- Flexible Orders: Whether you need large quantities or small orders, we can accommodate your needs and adjust to your delivery schedule.

5. Reliable Delivery and Logistics

- On-Time Delivery: Our efficient logistics and supply chain management ensure timely delivery of your 7075 aluminum plates, minimizing delays and downtime.

- Global Shipping: We are equipped to handle international shipments, providing reliable delivery of 7075 aluminum sheets to customers worldwide.

6. Exceptional Customer Service

- Dedicated Support: We prioritize customer satisfaction by offering responsive service, addressing any concerns promptly, and ensuring a smooth ordering process for your 7075 aluminum plates.

- After-Sales Care: Our commitment extends beyond the sale with ongoing support and assistance to ensure your continued satisfaction with our 7075 aluminum sheets.

7. Commitment to Sustainability and Compliance

- Eco-Friendly Practices: We adhere to sustainable practices and ensure that our 7075 aluminum plates comply with environmental regulations.

- Quality Certifications: Our facilities and processes are certified to meet industry standards, reflecting our dedication to quality and compliance.

8. Advanced Technology and Innovation

- State-of-the-Art Facilities: We use the latest technology and machinery to produce high-quality 7075 aluminum sheets, meeting modern industry demands.

- Continuous Improvement: We invest in research and development to continuously enhance our products and services, ensuring that we provide the best solutions for your needs.

Choose us as your 7075 aluminum sheet supplier, our rich expertise, customized solutions and large inventory with fast delivery make us your best choice of 7075 aluminum sheet supplier.