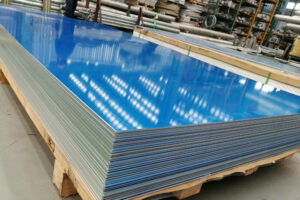

Are you searching for high-quality 6063 Aluminum Sheet suppliers and manufacturers? As one of the professional 6063 aluminum sheet suppliers and manufacturers in China, the aluminum sheet we provide meets industry standards and has a very high-cost performance.

We provide high-quality 6063 aluminum sheets, known for their excellent strength-to-weight ratio, corrosion resistance, and ease of processing. These materials are widely used in architectural, structural, and manufacturing applications. Whether you require standard or custom sizes, we ensure prompt delivery and reliable service.

For detailed pricing information and to view our current 6063 aluminum sheet inventory, please contact us for 6063 aluminum sheet prices directly.

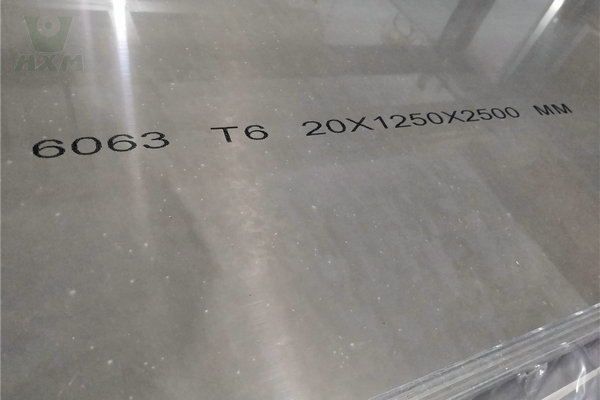

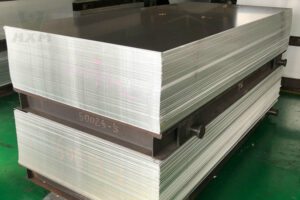

6063 Aluminum Sheets Specifications

Standards: ASTM, ASME, AMS, GB/T, JIS

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: O, T3, T4, T6, T651, etc.

Delivery Time: 7-20 days.

6063 Aluminum Sheet & Plate Data Sheet

Aluminum Plate 6063 Equivalent Grades:

| Standard/Specification | Equivalent Grade |

|---|---|

| EN (European Standard) | EN AW-6063 |

| AA (Aluminum Association) | AA6063 |

| ASTM (American Society for Testing and Materials) | A96063 |

| International Standard | AL 6063 |

| JIS (Japanese Industrial Standard) | JIS A6063 |

Chemical Composition Of 6063 Aluminum Sheets:

| Element | Composition Range (% by weight) |

|---|---|

| Al | Balance |

| Si | 0.2 – 0.6 |

| Fe | 0.35 max |

| Cu | 0.1 max |

| Mn | 0.1 max |

| Mg | 0.45 – 0.9 |

| Cr | 0.1 max |

| Zn | 0.1 max |

| Ti | 0.1 max |

For detailed specifications or to place an order, please contact us directly and we will reply within 24 hours – your trusted 6063 Aluminum Sheet Supplier.

Mechanical Properties Of 6063 Aluminium Plates:

| Temper | Ultimate Tensile Strength (UTS) | Yield Strength (YS) | Elongation | Hardness |

|---|---|---|---|---|

| O (Soft) | 145 – 175 MPa (21 – 25 ksi) | 35 – 55 MPa (5 – 8 ksi) | 18 – 30% | 30 – 40 HB |

| T4 (Solution Heat-Treated) | 185 – 215 MPa (27 – 31 ksi) | 130 – 150 MPa (19 – 22 ksi) | 10 – 15% | 60 – 75 HB |

| T6 (Solution Heat-Treated and Aged) | 240 – 290 MPa (35 – 42 ksi) | 210 – 240 MPa (30 – 35 ksi) | 8 – 12% | 70 – 90 HB |

| T5 (Heat-Treated to an Intermediate Strength) | 205 – 235 MPa (30 – 34 ksi) | 140 – 165 MPa (20 – 24 ksi) | 12 – 18% | 55 – 70 HB |

These properties make 6063 aluminum alloy sheet flexible for a variety of structural, architectural, and manufacturing applications, depending on the strength and workability required.

Physical Properties Of 6063 Aluminum Plate:

| Property | Value |

|---|---|

| Density | 2.68 – 2.72 g/cm³ (2680 – 2720 kg/m³) |

| Melting Point | 600 – 650°C (1112 – 1202°F) |

| Thermal Conductivity | 200 – 220 W/m·K |

| Electrical Conductivity | 32 – 35 % IACS (International Annealed Copper Standard) |

| Modulus of Elasticity | 68 – 70 GPa (9.9 – 10.1 x 10³ ksi) |

| Specific Heat Capacity | 0.897 J/g·K |

| Thermal Expansion Coefficient | 23 – 25 x 10⁻⁶ /K |

| Poisson’s Ratio | ~0.33 |

The data presented by each aluminum metal manufacturer will be slightly different. If you need confirmed information, you can contact us directly. We can also provide you with free samples to test whether they are suitable for your project needs!

Tempers Of 6063 Aluminum Sheet:

-

Temper O: Provides maximum formability and is ideal for applications where extensive shaping is required but strength is less critical.

-

Temper T4: Offers good strength and workability, suitable for applications that need a balance between formability and strength.

-

Temper T5: Provides an intermediate strength level, making it suitable for applications where moderate strength is needed without compromising too much on workability.

-

Temper T6: Delivers the highest strength among the tempers listed, making it suitable for demanding structural and architectural applications where high strength is crucial.

These tempers enable 6063 aluminum sheets to be tailored for a range of applications, from highly decorative architectural elements to structural components requiring high strength.

As a trusted 6063 aluminum sheet manufacturer and supplier, Huaxiao Metal serves customers in the global construction, automotive, marine and electrical industries. Whether you are purchasing wholesale, OEM or special project, we have the capabilities and services to meet your needs.

Contact us today for a 6063 aluminum sheet quote, free samples or technical consultation.

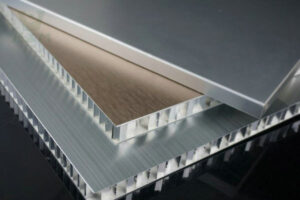

6063 Aluminum Plate Application

Architectural Applications:

- Building Facades: Ideal for creating visually appealing and durable building exteriors.

- Window Frames and Door Frames: Provides strength and an aesthetically pleasing finish for frames in residential and commercial buildings.

- Curtain Walls: Used in modern high-rise buildings for their strength and weather resistance.

Structural Components:

- Support Beams and Columns: Utilized in structural frameworks where lightweight yet strong materials are required.

- Brackets and Mounts: Used for various mounting applications due to its strength and ease of machining.

Manufacturing:

- Automotive Parts: Employed in the production of components where weight reduction and strength are critical.

- Machined Parts: Used for custom parts and components in various machinery and equipment.

Aerospace:

- Aircraft Components: Beneficial in aerospace applications where strength-to-weight ratio is crucial.

Marine Applications:

- Boat and Ship Components: Resists corrosion in marine environments, making it suitable for various marine components.

Decorative Uses:

- Interior Design Elements: Commonly used in interior applications such as decorative panels, fixtures, and trim due to its good surface finish and ease of fabrication.

Transportation:

- Railway and Bus Frames: Used in vehicles where lightweight and strong materials are necessary for structural integrity and performance.

Not sure if 6063 aluminum alloy is right for your project? Contact our technical team, and we will give you professional advice.

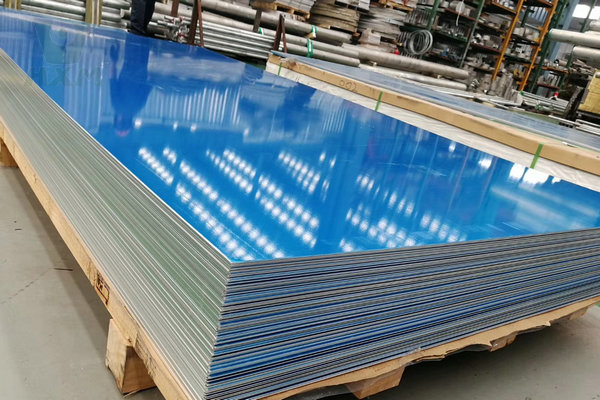

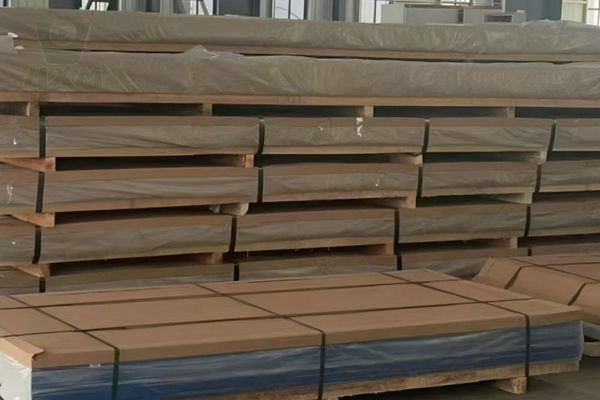

6063 Aluminum Sheet Packages

To ensure product safety during transportation, we provide robust export-standard packaging:

- Plastic film + kraft paper + wooden pallet/crate

- Edge protection and anti-scratch layer

- Custom labels and markings as per request

- Moisture-proof and rust-proof sealing for sea shipment

The following is our company’s conventional export packaging for aluminum plates. If you have special packaging requirements, our company can meet them. We very much hope to become one of your aluminum plate suppliers!

Get the latest 6063 aluminum sheet price directly from our sales team! We respond within 12 hours and offer free technical advice and samples.

FAQ

What is 6063 Aluminum Sheet?

6063 aluminum sheet is a flat, thin piece of aluminum alloy known for its good strength, corrosion resistance, and ease of fabrication. It’s commonly used in architectural and structural applications.

Are you looking for a reliable 6063 aluminum sheet supplier with favorable prices and stable quality? Huaxiao Metal focuses on supplying and exporting high-quality 6063 aluminum sheets to the global market. With more than 15 years of manufacturing experience and advanced production lines, we can provide precision-cut aluminum sheets according to your needs.

Is 6063 Aluminium Sheet Suitable for Welding?

Yes, 6063 aluminum sheet is suitable for welding. It has good weldability, which makes it a popular choice for various welding applications. However, to achieve the best results, proper welding techniques and considerations should be applied, such as ensuring clean surfaces and using appropriate filler materials.

Can 6063 Aluminum Sheet Be Bent?

Yes, the 6063 aluminum sheet can be bent. Its excellent workability and good machinability make it suitable for bending and forming. However, the bending process should be done carefully to avoid problems such as cracking or warping. Here are some key considerations:

Thickness: Thicker sheets may be more difficult to bend and may require specialized equipment.

Bending Radius: A minimum bending radius should be considered to avoid damaging the material. The radius is usually determined by the thickness of the sheet and the specific bending process used.

Tooling: Using the proper tools and techniques, such as a press brake or roll bender, can help achieve clean and precise bends.

Heat Treatment: If the aluminum sheet is in a specific temper, such as T6, it may be less flexible compared to other tempers such as O or T4. Heat treatment affects how easily the sheet can be bent.

Overall, the properties of the 6063 aluminum sheet make it suitable for bending as long as the proper techniques and considerations are used.

6063 Aluminum Plates VS Other Aluminum Alloys

6061 vs. 6063 Aluminum Plates

6061 Aluminum Plates:

6061 Aluminium Sheets

- Strength: Higher tensile and yield strength. Tensile strength typically ranges from 240 – 290 MPa (35 – 42 ksi), and yield strength ranges from 210 – 240 MPa (30 – 35 ksi).

- Workability: Good; machinability is slightly more challenging than 6063 but still excellent. Can be heat-treated to enhance strength.

- Corrosion Resistance: Good, though less than 6063. Suitable for moderate corrosion environments.

- Applications: Ideal for structural components, aerospace parts, and automotive applications requiring higher strength.

6063 Aluminum Plates:

- Strength: Moderate tensile and yield strength. Typically ranges from 240 – 290 MPa (35 – 42 ksi) tensile strength and 210 – 240 MPa (30 – 35 ksi) yield strength.

- Workability: Excellent; very easy to machine, extrude, and fabricate. Ideal for complex shapes and fine finishes.

- Corrosion Resistance: Excellent; provides good resistance to corrosion, making it suitable for outdoor and marine environments.

- Applications: Commonly used in architectural elements, window and door frames, and other applications where ease of fabrication and corrosion resistance are key.

6063 vs. 7075 Aluminum Plates

6063 Aluminum Plates:

- Strength: Moderate tensile and yield strength. Typically ranges from 240 – 290 MPa (35 – 42 ksi) tensile strength and 210 – 240 MPa (30 – 35 ksi) yield strength.

- Workability: Excellent; easy to machine and fabricate, ideal for complex and detailed work.

- Corrosion Resistance: Excellent; very good corrosion resistance.

- Applications: Architectural applications, structural components, and decorative elements where corrosion resistance and good workability are important.

7075 Aluminum Plates:

7075 Aluminum Sheets

- Strength: Much higher than 6063. Tensile strength typically ranges from 505 – 575 MPa (73 – 83 ksi) and yield strength from 435 – 505 MPa (63 – 73 ksi).

- Workability: More challenging; harder to machine and weld compared to 6063.

- Corrosion Resistance: Lower than 6063; less suited for highly corrosive environments.

- Applications: Aerospace, military, and high-strength applications where maximum strength is required.

6063 vs. 3003 Aluminum Plates

6063 Aluminum Plates:

- Strength: Moderate tensile and yield strength. Typically ranges from 240 – 290 MPa (35 – 42 ksi) tensile strength and 210 – 240 MPa (30 – 35 ksi) yield strength.

- Workability: Excellent; easy to machine and fabricate.

- Corrosion Resistance: Excellent; good corrosion resistance.

- Applications: Architectural elements, structural components, and other uses where ease of fabrication and corrosion resistance are crucial.

3003 Aluminum Plates:

3003 Aluminum Sheets

- Strength: Lower than 6063. Tensile strength typically ranges from 130 – 175 MPa (19 – 25 ksi) and yield strength from 115 – 155 MPa (17 – 22 ksi).

- Workability: Excellent; very easy to machine and form.

- Corrosion Resistance: Good; performs well in corrosive environments.

- Applications: Cooking utensils, chemical tanks, and applications needing good workability and corrosion resistance without high strength.

6063 vs. 2024 Aluminum Plates

6063 Aluminum Plates:

- Strength: Moderate tensile and yield strength. Typically ranges from 240 – 290 MPa (35 – 42 ksi) tensile strength and 210 – 240 MPa (30 – 35 ksi) yield strength.

- Workability: Excellent; very easy to machine and fabricate.

- Corrosion Resistance: Excellent; good resistance to corrosion.

- Applications: Architectural applications, window and door frames, and other uses where good workability and corrosion resistance are important.

2024 Aluminum Plates:

2024 Aluminum Sheets

- Strength: Higher than 6063. Tensile strength typically ranges from 470 – 530 MPa (68 – 77 ksi) and yield strength from 370 – 430 MPa (54 – 62 ksi).

- Workability: Less favorable compared to 6063; more challenging to machine and handle.

- Corrosion Resistance: Lower than 6063; not ideal for highly corrosive environments.

- Applications: Aerospace structures and other high-strength applications where strength is more critical than corrosion resistance.

In Conclusion

-

6061 vs. 6063: 6061 offers higher strength, while 6063 excels in machinability and corrosion resistance.

-

6063 vs. 7075: 7075 provides much higher strength but is more challenging to work with, and has lower corrosion resistance compared to 6063.

-

6063 vs. 3003: 3003 offers lower strength but excellent workability and corrosion resistance, making it suitable for non-structural applications.

-

6063 vs. 2024: 2024 has higher strength but lower corrosion resistance and more challenging workability compared to 6063.