Are you searching for high-quality 2024 Aluminum Sheet suppliers and manufacturers? As one of the professional 2024 aluminum sheet suppliers and manufacturers in China, the aluminum sheet we provide meets industry standards and has a very high-cost performance. Whether you are using it for food packaging or other applications, our 2024 aluminum plates can meet your needs.

Known for its exceptional strength-to-weight ratio and superior fatigue resistance, 2024 aluminum is the material of choice for aerospace, automotive, and high-performance engineering. Our aluminum sheet meets rigorous industry standards, delivering high-quality durability and reliability.

I hope you can find the information you need here, feel free to contact us for more details and the latest 2024 aluminum sheet price.

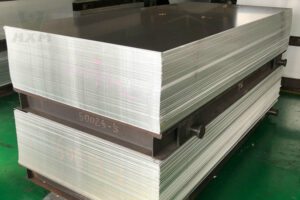

2024 Aluminum Sheets Specifications

Standards: ASTM, ASME, AMS, GB/T, JIS

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: O, T3, T4, T42, T81, T351, T851, etc.

Delivery Time: 7-20 days.

2024 Aluminum Sheet & Plate Data Sheet

Aluminum Plate 2024 Equivalent Grades:

Here is a list of equivalent grades for Aluminum 2024 Plate across different standards:

| Standard | Equivalent Grade |

|---|---|

| UNS | A92024 |

| ISO | AlCu4Mg1 |

| ASTM | B211, B221, B241, B316 |

| EN | AW-2024 |

| JIS | 2024 |

| GB/T (China) | 2A12, GB/T 3190-2008 |

| AA | 2024 |

This table provides a quick reference to the equivalent grades of Aluminum 2024 across different standards.

Chemical Composition Of 2024 Aluminum Sheets:

| Element | Al | Cu | Mg | Mn | Fe | Si | Zn | Ti | Cr | Other elements, each | Other elements, total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Percentage (% by weight) | 90.7 – 94.7 | 3.8 – 4.9 | 1.2 – 1.8 | 0.3 – 0.9 | 0.5 max | 0.5 max | 0.25 max | 0.15 max | 0.1 max | 0.05 max | 0.15 max |

For detailed specifications or to place an order, please contact us directly and we will reply within 24 hours – your trusted 2024 Aluminum Sheet Supplier.

Mechanical Properties Of 2024 Aluminium Alloy Plates:

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

| O | 290-340 | 115-165 | 25-30 | 70-110 |

| T3 | 345-455 | 275-345 | 15-20 | 120-150 |

| T4 | 355-460 | 275-345 | 15-20 | 120-150 |

| T42 | 370-460 | 290-345 | 16-20 | 130-150 |

| T81 | 340-435 | 290-345 | 15-20 | 120-140 |

| T351 | 345-460 | 275-345 | 15-20 | 120-150 |

| T851 | 380-500 | 310-415 | 13-17 | 140-160 |

The data given by different aluminum meetal manufacturers may be differnt. If you want to determine whether our company’s 2024 aluminum sheets suit your project, we can provide free samples for you to test.

Physical Properties Of 2024 Aluminum Plate:

| Property | Value |

|---|---|

| Density | 2.78 g/cm³ (2780 kg/m³) |

| Melting Point | Approximately 650°C (1202°F) |

| Thermal Conductivity | 120 W/m·K |

| Electrical Conductivity | 40-50% IACS (International Annealed Copper Standard) |

| Specific Heat Capacity | 0.897 J/g·K |

| Coefficient of Thermal Expansion | 22.8 x 10^-6/K (22.8 µm/m·K) |

| Modulus of Elasticity | 73.1 GPa (10600 ksi) |

| Poisson’s Ratio | 0.33 |

The data presented by each aluminum metal manufacturer will be slightly different. If you need confirmed information, you can contact us directly. We can also provide you with free samples to test whether they are suitable for your project needs!

Tempers Of 2024 Aluminum Sheet:

2024 O (Annealed): Fully soft, with high formability. Typically used where ductility and easy machining are needed.

2024-T3 (Solution Heat-Treated, Naturally Aged): Provides a balance of strength and ductility. Commonly used in aerospace applications.

2024-T4 (Solution Heat-Treated, Artificially Aged): Offers higher strength compared to T3. Suitable for aerospace and high-performance parts.

2024-T42 (Solution Heat-Treated, Aged to Higher Strength): Delivers higher strength than T4, used for parts requiring enhanced strength.

2024-T81 (Solution Heat-Treated, Stress-Relieved by Stretching, Aged): Balances strength and ductility, used where dimensional stability and strength are important.

2024-T351 (Solution Heat-Treated, Stress-Relieved by Stretching, Aged): Similar to T81 but with improved dimensional stability, often used in structural applications.

2024-T851 (Solution Heat-Treated, Stress-Relieved by Stretching, Further Aged): Provides the highest strength among the 2024 tempers, ideal for high-load applications.

2024 Aluminum Plate Application

Aircraft Fittings

Gears and Shafts

Bolts

Clock Parts

Computer Parts

Couplings

Fuse Parts

Hydraulic Valve Bodies

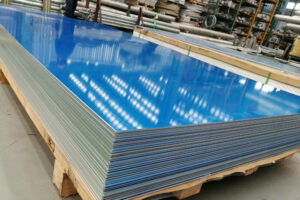

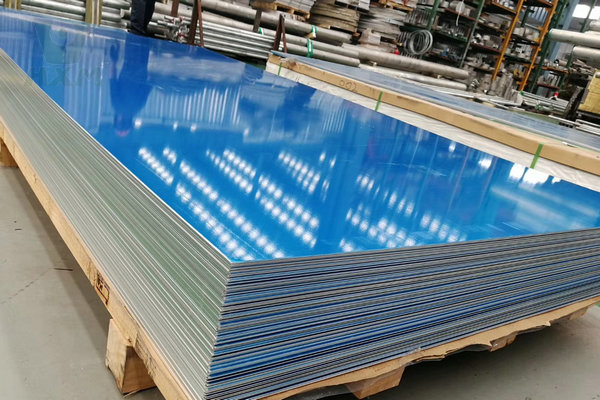

2024 Aluminum Sheet Packages

The following is our company’s conventional export packaging for aluminum plates. If you have special packaging requirements, our company can meet them. We very much hope to become one of your aluminum plate suppliers!

FAQ

What is 2024 Aluminum Sheet?

2024 aluminum sheet is a high-strength, heat-treatable aluminum alloy commonly used in aerospace and structural applications. Known for its excellent strength-to-weight ratio, it provides high tensile strength and good fatigue resistance. It is often used in aircraft structures, automotive components, and other high-performance applications.

Is 2024 Aluminium Sheet Suitable for Welding?

2024 aluminum sheet is not generally suitable for welding due to its high copper content, which can result in reduced weld strength and increased risk of cracking. For applications requiring welding, alloys such as 6061 or 7075 are often preferred. However, 2024 can be welded if required using specialized techniques and filler materials.

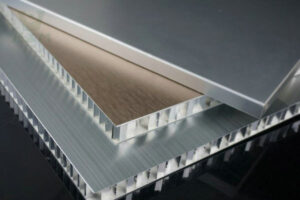

2024 Aluminum Plates VS Other Aluminum Alloys?

2024 Aluminum Plate vs 6061 Aluminum Plate

6061 Aluminium Sheets

- Strength: 2024 offers higher tensile and yield strength compared to 6061, making it more suitable for high-stress applications.

- Corrosion Resistance: 6061 has better corrosion resistance than 2024 due to its higher silicon and magnesium content.

- Weldability: 6061 is easier to weld, whereas 2024 has poorer weldability.

- Applications: 2024 is primarily used in aerospace, while 6061 is more commonly used in structural and mechanical applications.

2024 Aluminum Plate vs 7075 Aluminum Plate

7075 Aluminum Sheets

- Strength: 7075 generally provides higher strength than 2024, making it one of the strongest aluminum alloys.

- Corrosion Resistance: 2024 has lower corrosion resistance compared to 7075, which performs better in this regard.

- Toughness: 2024 is generally tougher and less brittle than 7075, which can be more prone to cracking under certain conditions.

- Applications: 7075 is used in high-load applications such as aerospace and military, while 2024 is also used in aerospace but where slightly less strength is required.

Can 2024 Aluminum Sheet Be Bent?

Yes, 2024 aluminum plates can be bent, but their bending performance depends on the heat treatment condition and the thickness of the plate.

Bending Factors:

Heat Treatment Condition:

- In the T3 and T4 tempers, 2024 aluminum plates are solution heat-treated and aged, which provides high strength but can make bending more challenging.

- In the O (annealed) temper, 2024 aluminum is fully softened and has higher formability and bending capability, though with lower strength.

Thickness:

- Thinner plates are generally easier to bend compared to thicker plates.

Bending Radius:

- For higher-strength conditions like 2024-T3 or 2024-T4, using a larger bending radius is recommended to avoid cracking or breaking.

Processing Tips:

- Preheating: In some cases, preheating the aluminum plate can improve its bending capability, especially for high-strength tempers.

- Bending Tools: Using appropriate tools and dies can help achieve a more uniform bend.

In summary, while 2024 aluminum plates can be bent, their high strength can make bending more difficult, particularly in harder tempers. Selecting the appropriate temper and processing techniques is crucial for successful bending.