1100 Aluminum Sheets Specifications

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: O, H14, H18, etc.

Delivery Time: 7-20 days.

Standards: ASTM B209 / ASME SB209/DIN 1725/JIS H4000

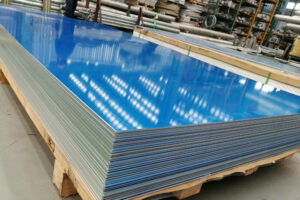

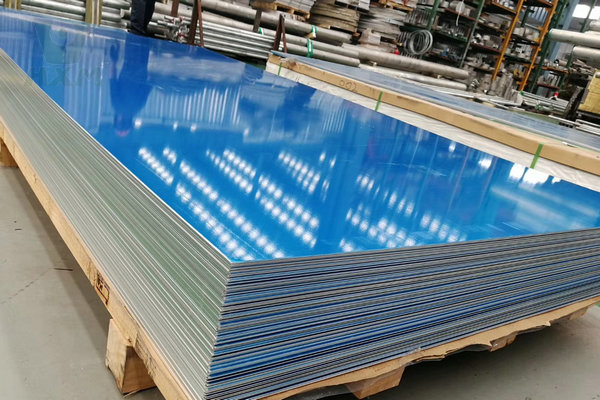

Description of 1100 Aluminum Sheet & Plate

1100 aluminum sheets are known for their high corrosion resistance, excellent thermal and electrical conductivity, and superior machinability. These properties make them ideal for various applications, such as chemical processing equipment, heat exchangers, and food industry machinery.

As one of the leading 1100 aluminum sheet suppliers, HXM Metal ensures that all of our products meet the highest international standards, including ASTM B209, ISO 6361, and EN 573-3. Our 1100 aluminum sheets are available in a variety of tempers to suit your specific needs, whether you require high strength or maximum flexibility.

Choose HXM Metal and we provide you with high-quality 1100 aluminum sheets that offer reliability and performance for your project. Contact us today to inquire about 1100 aluminum sheet prices!

1100 Aluminium Sheets & Plates Data Sheet

Equivalent Specifications of Aluminium 1100 Sheet & Plate

| UNS | USA | Japan | France | ISO |

| A91100 | AA1100 | JIS A1100P | NF 1100 | Al 99.0 Cu. |

Chemical Composition of 1100 Aluminum Plates

The 1100 aluminum plate is known for its high purity and excellent corrosion resistance. Below is the detailed chemical composition:

| Element | Composition (%) |

|---|---|

| Al | 99.0% min |

| Cu | 0.05 – 0.20 |

| Fe | 0.95 max |

| Si | 0.95 max |

| Zn | 0.10 max |

| Mn | 0.05 max |

| Other Elements | 0.15 max (total) |

The primary component of 1100 aluminum is aluminum itself, comprising at least 99.0% of the material. Small amounts of other elements like copper, iron, silicon, zinc, and manganese are present in varying amounts, each contributing to the alloy’s properties.

- Aluminum (Al): The major constituent, providing the base for this alloy.

- Copper (Cu): Adds strength and hardness.

- Iron (Fe) and Silicon (Si): Present as impurities but are kept to a minimum to maintain purity.

- Zinc (Zn) and Manganese (Mn): Minor elements that contribute to specific characteristics.

This composition makes the 1100 aluminum plate suitable for applications requiring excellent corrosion resistance and high workability, such as chemical processing equipment, heat exchangers, and decorative applications.

For more detailed information about the 1100 aluminum plate and its applications, feel free to contact us!

Mechanical Properties of 1100 Aluminium Sheets

The 1100 aluminum sheet is renowned for its excellent mechanical properties, making it a versatile material for various applications. Below are the key mechanical properties of 1100 aluminum sheets:

| Property | Typical Values |

|---|---|

| Tensile Strength | Approximately 13,000 psi (90 MPa) |

| Yield Strength | Approximately 5,000 psi (34 MPa) |

| Elongation | 5-35% (depending on the temper) |

| Brinell Hardness | 35 HB |

| Modulus of Elasticity | 69 GPa (10,000 ksi) |

| Shear Strength | 8,000 psi (55 MPa) |

| Fatigue Strength | 5,000 psi (34 MPa) |

These mechanical properties make 1100 aluminum sheets suitable for a variety of applications, including chemical equipment, reflectors, heat exchangers, and food industry equipment, where high corrosion resistance and good formability are required.

For more detailed information about 1100 aluminum plates and their applications, feel free to contact us!

Physical Properties of 1100 Aluminum Plates

1100 aluminum plates are known for their excellent physical properties, which make them suitable for a wide range of applications. Below are the key physical properties:

| Property | Value |

|---|---|

| Density | 2.71 g/cm³ |

| Melting Point | 643 – 657°C (1189 – 1215°F) |

| Thermal Conductivity | 222 W/m·K |

| Electrical Conductivity | 53% IACS |

| Coefficient of Thermal Expansion | 23.6 µm/m·°C |

| Specific Heat Capacity | 0.897 J/g·°C |

| Modulus of Elasticity | 69 GPa (10,000 ksi) |

These physical properties make 1100 aluminum plates ideal for applications that require good thermal and electrical conductivity, lightweight, and good formability, such as in heat exchangers, chemical processing equipment, and electrical components.

For more detailed information about 1100 aluminum plates and their applications, feel free to contact us!

Tempers of 1100 Aluminium Plates

At HXM Metal, we offer 1100 aluminum plates in various tempers to meet the specific needs of our customers. The temper designation indicates the mechanical and physical properties of the aluminum plate, which are achieved through specific heat treatment or mechanical processing. Here are the common tempers available for 1100 aluminum sheets:

| Temper | Description |

|---|---|

| H14 | Strain-hardened to a moderate degree. Offers a balance of strength and formability. |

| H18 | Strain-hardened to the fullest extent. Provides maximum strength with lower formability. |

| H22 | Strain-hardened and partially annealed. Provides a good balance between strength and ductility. |

| H24 | Strain-hardened and partially annealed to a greater degree than H22. Offers higher strength. |

| H32 | Strain-hardened and stabilized. Provides good strength with better ductility than H18. |

| O | Annealed, softest temper. Offers excellent formability and high ductility, suitable for complex shapes. |

| F | As fabricated, no special control over the mechanical or thermal conditions. |

- H14 (Half-Hard): This temper is achieved through strain-hardening to a moderate degree, providing a good balance of strength and formability, making it suitable for various applications that require moderate mechanical strength and good workability.

H18 (Full-Hard): Strain-hardened to the fullest extent, this temper provides the highest strength among the 1100 aluminum tempers but offers lower formability. It is ideal for applications where maximum strength is required.

H22 (Quarter-Hard): This temper is achieved by strain-hardening followed by partial annealing. It offers a good balance between strength and ductility, making it suitable for applications requiring moderate strength and good formability.

H24 (Half-Hard): Strain-hardened and partially annealed to a greater degree than H22, H24 provides higher strength while maintaining good ductility, making it suitable for structural applications.

H32 (Stabilized): This temper involves strain-hardening and stabilization, providing good strength with better ductility compared to H18. It is ideal for applications requiring both strength and some degree of formability.

O (Annealed): The softest temper, achieved through annealing. This temper offers excellent formability and high ductility, making it suitable for complex shapes and deep drawing applications.

F (As Fabricated): This temper indicates that the aluminum sheet is in the “as fabricated” condition, with no special control over its mechanical or thermal properties. It is used when specific properties are not critical.

At HXM Metal, we ensure that our 1100 aluminum sheet meets the highest quality and performance standards, providing you with the correct temper for your specific needs. For more details or to place an order, please contact us and we will provide you with 1100 aluminum plate prices directly!

1100 Aluminum Sheet Application

The 1100 aluminum sheet is highly versatile, making it suitable for a wide range of applications. As one of the leading 1100 aluminum sheet suppliers, HXM Metal is proud to provide high-quality products that meet the diverse needs of our customers. Here are some of the key applications of the 1100 aluminum sheet:

1. Chemical Processing Equipment

1100 aluminum sheets are widely used in chemical processing equipment due to their excellent corrosion resistance. They are particularly effective in environments where they are exposed to chemicals and atmospheric conditions.

2. Heat Exchangers

With its high thermal conductivity, the 1100 aluminum sheet is an ideal material for heat exchangers. This property ensures efficient heat transfer, making it suitable for use in heating and cooling systems.

3. Food Industry Equipment

The 1100 aluminum sheet is commonly used in the food industry for manufacturing equipment such as tanks, pipes, and cooking utensils. Its high corrosion resistance ensures that it does not react with food products, maintaining hygiene and safety standards.

4. Reflectors and Lighting Equipment

Due to its excellent reflectivity, the 1100 aluminum sheet is often used in the production of reflectors and lighting equipment. This application benefits from the material’s ability to reflect light efficiently, enhancing the performance of lighting fixtures.

5. Architectural Applications

In the architectural industry, the 1100 aluminum sheet is used for decorative purposes, such as in building facades and interior design elements. Its ability to be easily formed and its aesthetic appeal make it a popular choice for designers and architects.

6. Packaging Materials

The 1100 aluminum sheet is also used in packaging, particularly for packaging food products. Its non-toxic nature and high corrosion resistance ensure that it keeps the contents safe and preserves their quality.

7. Signage and Nameplates

The excellent workability of the 1100 aluminum sheet makes it a preferred material for signage and nameplates. It can be easily cut, engraved, and formed into various shapes, providing durability and a professional appearance.

As one of the trusted 1100 aluminum sheet suppliers in China, HXM Metal ensures that our products are manufactured to the highest standards, providing reliability and performance in all of these applications. For more information or to place an order, please contact us!