China 7050 Aluminum Coils Suppliers & Manufacturers

As one of the leading and trusted 7050 Aluminum Coil Suppliers and Manufacturers in China, we offer aluminum coils that excel in high-performance environments, including aerospace and military fields. Our 7050 aluminum coils are known for their superior tensile strength, stress corrosion resistance, and fatigue durability.

Explore our 7050 aluminum coil price range to find the best product for your high-strength needs. Whether you are looking for aluminum coils for structural components or aluminum coils for specialized high-performance parts, our products offer outstanding quality and performance.

Contact us to learn more about our 7050 aluminum coils and get a quote customized to your specifications.

7050 Aluminium Coil Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.2~300mm

Width: 500~2500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

7050 Aluminum Coil Data Sheet

Equivalent Grades Of Aluminum 7050 Coil

| Standard | 7050 Aluminum | Equivalent Grades | Notes |

|---|---|---|---|

| Aluminum Association (AA) | 7050 | – | Standard aluminum alloy designation |

| International Organization for Standardization (ISO) | 7050 | 3.4164 | Comparable performance to 7050 |

| Deutsches Institut für Normung (DIN) | – | EN AW-7050 | Standard corresponding designation |

| British Standards (BS) | – | 7075-T6 | 7075-T6 is often used interchangeably with 7050 in UK standards |

| Japanese Industrial Standards (JIS) | – | A7075-T6 | A7075-T6 is similar to 7050 under JIS standards |

| Chinese National Standards (GB) | – | 7075-T6 | 7075-T6 is commonly used as an equivalent in China |

Chemical Composition of 7050 Aluminum Coil

Below is a typical chemical composition for 7050 aluminum coil:

| Element | Chemical Composition (%) |

|---|---|

| Al | Balance (approximately 90.7 – 94.7%) |

| Zn | 5.7 – 6.7% |

| Cu | 2.0 – 2.6% |

| Mg | 2.2 – 2.8% |

| Mn | 0.1 – 0.3% |

| Cr | 0.04 – 0.35% |

| Si | 0.1% max |

| Fe | 0.2% max |

| Ti | 0.05 – 0.15% |

| Other Elements | Each 0.05% max, Total 0.15% max |

Mechanical Properties and Tempers of 7050 Aluminium Coil

| Property | 7050-T6 | 7050-T7451 | 7050-T651 | 7050-T76 |

|---|---|---|---|---|

| Yield Strength (MPa) | 503 – 572 | 483 – 540 | 483 – 552 | 483 – 552 |

| Ultimate Tensile Strength (MPa) | 572 – 641 | 552 – 620 | 552 – 621 | 552 – 621 |

| Elongation (%) | 8 – 10 | 10 – 12 | 10 – 12 | 10 – 12 |

| Shear Strength (MPa) | 431 – 517 | 414 – 482 | 414 – 482 | 414 – 482 |

| Hardness (Brinell) | 150 – 180 | 145 – 175 | 145 – 175 | 145 – 175 |

As a well-known 7050 aluminum coil supplier and manufacturer in China, we not only provide high-quality products but also focus on establishing long-term cooperative relationships with customers. Whether in terms of price competitiveness or inventory adequacy, we strive to provide you with the most convenient purchasing experience. Our team is always on call to answer your questions, provide technical support, and ensure the smooth progress of your project. By choosing us, you will get not only a batch of aluminum coils but also a trustworthy partner. We look forward to working with you to push your project to new heights!

For high-quality 7050 aluminum coil and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7050 Aluminum Coils Metal

7050 aluminum alloy is a high-strength aluminum alloy widely used in aerospace and other applications requiring high strength and corrosion resistance. 7050 aluminum coil can have a variety of different states according to its heat treatment process, and each state has its specific performance and applicable scenarios. The following are several common states (Tempers) of 7050 aluminum coil and their characteristics:

7050-T6

Features: the 7050-T6 state is the most commonly used heat treatment state in 7050 aluminum alloy. After T6 treatment, the 7050 aluminum coil has excellent strength, hardness, and corrosion resistance after dissolution treatment and artificial aging.

Application: Mainly used in structural parts, aircraft wings, and fuselage parts in the aerospace field.

7050-T7451

Features: The 7050-T7451 state has a higher resistance to stress corrosion cracking than the T6 state. Through a special heat treatment process and stabilization treatment, the T7451 state provides better comprehensive performance, especially tolerance to the environment.

Application: Suitable for applications with higher requirements for stress corrosion cracking resistance, such as aircraft structural parts and high-load components.

7050-T651

Features: The 7050-T651 state is a modified version of the T6 state with higher processability. By performing tensile stress release treatment after heat treatment, the internal stress is reduced, thereby improving the mechanical properties and processing performance.

Application: Widely used in aluminum alloy parts with complex structures, such as aircraft fuselage structural parts.

7050-T76

Features: The 7050-T76 state is an aged state that provides good mechanical properties and higher stress corrosion resistance. It is mainly solution treated and naturally aged to provide balanced performance characteristics.

Application: Suitable for structural parts and aviation components that require higher corrosion resistance and stability.

As a leading 7050 aluminum coil supplier in China, we focus on providing customers with high-strength, high-performance aluminum products. We are not only an aluminum metal manufacturer, but also your trusted partner. Our 7050 aluminum coil adopts advanced production technology and strict quality control to ensure that each roll of aluminum has excellent mechanical properties and corrosion resistance, suitable for high-demand fields such as aerospace and defense industries. At the same time, we maintain sufficient inventory to ensure fast delivery to meet your urgent needs.

Applications of 7050 Aluminum Coil Metal

Aerospace Industry

Defense Industry

- Military Aircraft: Employed in the construction of military aircraft where high strength and reliability are required.

- Armored Vehicles: Utilized in armored vehicles for its strength-to-weight ratio and durability.

High-Performance Automotive

- Racing Vehicles: Used in high-performance racing vehicles and components for its strength and lightweight properties.

- High-Stress Automotive Parts: Applied in automotive parts that experience high stress and require high strength.

Marine Industry

- Naval Vessels: Used in naval and other marine applications where strength and corrosion resistance are important, though less common than 5083 or 6061 in marine environments.

Structural Applications

- Heavy-Duty Structures: Suitable for heavy-duty structural components in various industries due to its high strength and resistance to deformation.

Tooling and Manufacturing

- High-Performance Tools: Used in manufacturing tooling and molds that require high strength and durability.

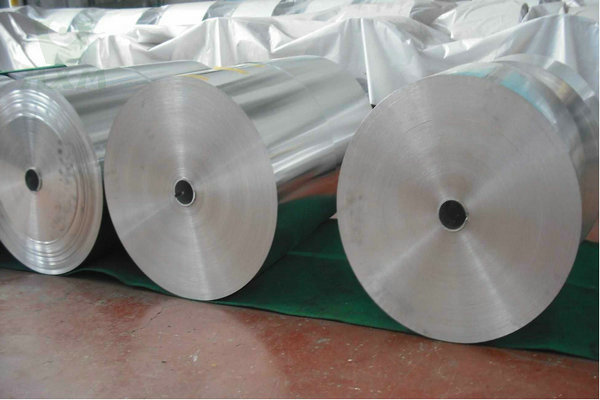

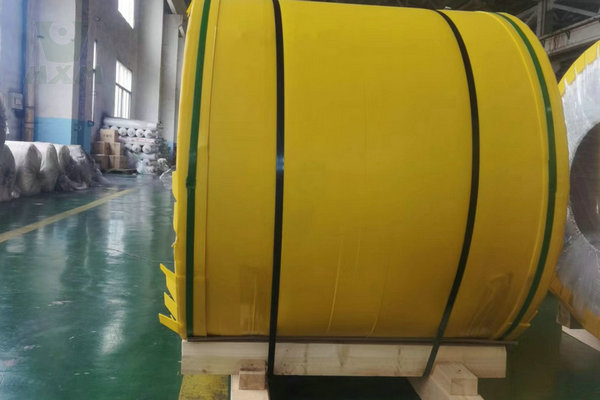

7050 Aluminum Coil Packages

The following is our company’s standard aluminum coil export packaging. If the customer has any packaging requirements, our company can meet them.

As a professional 7050 aluminum coil manufacturer, we provide a full range of customized services. From thickness, and width to surface treatment, we can adjust according to your specific needs. Whether it is a small batch purchase or a large order, we can complete it efficiently.

As a reliable supplier, we not only pay attention to product quality, but also pay attention to service details. Our team will provide you with technical support throughout the process to ensure that you get the most suitable solution. We have a large number of aluminum metal products in stock, contact us now to get details of our stock products and prices, etc.!

FAQ

What Is 7050 Aluminum Coil?

7050 Aluminum Coil is an alloy in the 7000 series, which is known for its high strength and resistance to stress corrosion cracking. It is alloyed mainly with zinc, along with smaller amounts of other elements like magnesium and copper.

7000 Series Aluminum

7050 Aluminum Coil VS Other Aluminum Coil:

| Property | 7050 Aluminum Coil | 6061 Aluminum Coil | 5052 Aluminum Coil | 3003 Aluminum Coil | 1100 Aluminum Coil |

|---|---|---|---|---|---|

| Tensile Strength | 505 – 570 MPa (73 – 83 ksi) | 240 – 310 MPa (35 – 45 ksi) | 210 – 260 MPa (30 – 38 ksi) | 110 – 180 MPa (16 – 26 ksi) | 90 – 140 MPa (13 – 20 ksi) |

| Yield Strength | 435 – 505 MPa (63 – 73 ksi) | 155 – 270 MPa (22 – 39 ksi) | 105 – 135 MPa (15 – 20 ksi) | 100 – 150 MPa (15 – 22 ksi) | 70 – 115 MPa (10 – 17 ksi) |

| Corrosion Resistance | Good (Stress corrosion resistant) | Good (General use) | Excellent (Marine environments) | Good (General use) | Excellent (General use) |

| Formability | Moderate | Excellent | Good | Excellent | Very Good |

| Weldability | Moderate | Excellent | Good | Good | Excellent |

| Applications | Aerospace, military, high-stress automotive | Aerospace, structural, automotive | Marine, automotive, tanks | Cooking utensils, storage tanks | Heat exchangers, decorative |

How Can I Get A Sample Of 7050 Aluminum Coils?

Please contact us directly and send us the material, specification, quantity, and delivery address of the samples you need.

Features of 7050 Aluminum Coil:

Alloy Series: 7000 Series

High Strength: 7050 is renowned for its high tensile and yield strength, making it suitable for structural components in demanding environments.

Stress Corrosion Resistance: The alloy is specifically designed to resist stress corrosion cracking, which is crucial for aerospace and military applications.

Good Fatigue Resistance: It has excellent fatigue resistance, which is essential for components subjected to cyclic loading.

Moderate Workability: While it has good mechanical properties, it is less formable compared to other aluminum alloys like 6061 or 5052.

Applications: It is commonly used in aerospace structures, military equipment, and high-performance automotive parts where strength and durability are critical.