As one of the top 6061 Aluminum Coil suppliers and manufacturers in China, HXM offers a range of aluminum coils that excel in both structural integrity and processability, making them ideal for a variety of applications, including aerospace, automotive, and industrial uses. Our 6061 aluminum coils are known for their excellent mechanical properties, including good strength, corrosion resistance, and ease of fabrication.

- Competitive 6061 Aluminum Coil Prices

- Large 6061 Aluminum Coil Stock

- Fast Delivery

Contact us today to learn more about our 6061 Aluminum Coil products and get 6061 Aluminum Coil prices!

6061 Aluminium Coil Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.2~300mm

Width: 500~2500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

6061 Aluminum Coil Data Sheet

Chemical Composition of 6061 Aluminum Coil

| Elements | Mg | Fe | Cu | Mn | Si | Cr | Ti | Zn | Others | Al |

| Content | 0.8-1.2 | 0.70 | 0.15-0.40 | 0.15 | 0.40-0.8 | 0.04-0.35 | 0.15 | 0.25 | 0.05 | Remains |

Mechanical Properties and Tempers of 6061 Aluminium Coil

| Typical Mechanical Properties of 6061 Aluminium Wire | |||

| Temper | Tensile Strength | Yield Strength | Elongation |

| KSI | KSI | % | |

| T451 | 35 | 21 | 25 |

| T651 | 45 | 40 | 17 |

Different Tempers of 6061 Aluminum Coils Metal

6061 aluminum alloy is a commonly used aluminum alloy that can be used to manufacture a variety of products, including sheet metal products. It can be processed in different states to obtain different mechanical properties and uses. The following are several common states of 6061 aluminum coil metal:

T6: This is one of the most common states in 6061 aluminum coil metal. In the T6 state, the aluminum alloy undergoes high-temperature solution treatment and then is rapidly quenched. This process gives it high strength and hardness. 6061 aluminum in T6 temper is commonly used in structural applications where strength is critical.

T4: In this state, the aluminum alloy has been solid solution treated and then aged naturally. It offers good formability and weldability while still possessing reasonable strength. 6061 aluminum in T4 temper is typically used in applications that require forming or bending.

T651 : Similar to the T6 condition, but with additional stretching after solution treatment. This stretching process reduces internal stress and enhances dimensional stability. 6061 aluminum in T651 condition is typically used in applications requiring precision parts and components where tight tolerances are required.

O : This is the annealed state of 6061 aluminum, completely softened. It has excellent formability but is less strong than in the processed state. 6061 aluminum in the O temper is suitable for applications where extensive forming is required or where strength is not a primary consideration.

T6511: This is a stretched version of the T651 condition, achieved through a stretching process. It offers properties similar to T651 aluminum, but with improved flatness and straightness. 6061 aluminum in the T6511 temper is typically used in applications where flatness is critical, such as aerospace components.

These are some of the most common states of 6061 aluminum coils, but there are others available, each offering specific properties suitable for different applications.

Applications of 6061 Aluminum Coil Metal

6061 Aluminum Coil is used across a wide range of industries due to its outstanding strength, processability, and corrosion resistance. Its applications range from aerospace and automotive to construction and marine, making it a versatile material suitable for many high-performance and structural uses.

Aircraft Structures: Used in aircraft frames, wings, and fuselage components due to its strength and lightweight properties.

Aerospace Components: Utilized in various aerospace parts that require both strength and good machinability.

Vehicle Frames and Components: Employed in automotive structural parts and components where strength-to-weight ratio is crucial.

Racing Components: Ideal for high-performance racing parts due to its balance of strength and formability.

Structural Applications: Used in construction for structural supports, beams, and columns due to its good strength and resistance to corrosion.

Architectural Components: Applied in architectural features like window frames and facades.

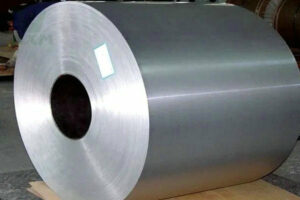

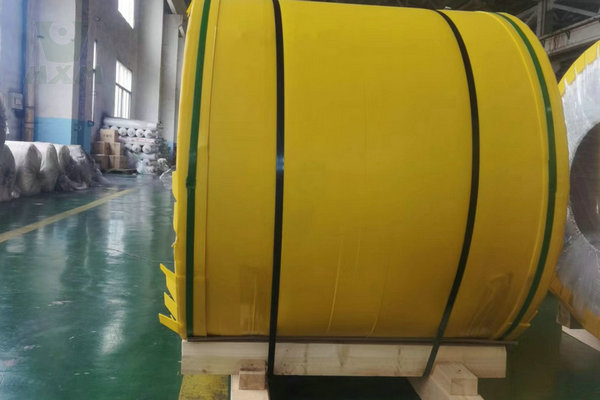

6061 Aluminum Coil Packages

The following is our company’s standard aluminum coil export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 6061 Aluminum Coil?

6061 Aluminum Coil is part of the 6000 series of aluminum alloys, which are primarily alloyed with magnesium and silicon.

6061 aluminum coil is a versatile, heat-treatable alloy known for its good mechanical properties, corrosion resistance, and workability. It is commonly used in a wide range of applications including structural components, aerospace parts, and industrial equipment, making it a popular choice for many demanding applications.

6000 Series Aluminum

6061 Aluminum Coil VS Other Aluminum Coil:

| Property | 6061 Aluminum Coil | 7075 Aluminum Coil | 2024 Aluminum Coil | 5052 Aluminum Coil | 7005 Aluminum Coil |

|---|---|---|---|---|---|

| Tensile Strength | 240 – 310 MPa (35 – 45 ksi) | 505 – 570 MPa (73 – 83 ksi) | 420 – 500 MPa (61 – 73 ksi) | 210 – 260 MPa (30 – 38 ksi) | 345 – 430 MPa (50 – 62 ksi) |

| Yield Strength | 155 – 270 MPa (22 – 39 ksi) | 435 – 505 MPa (63 – 73 ksi) | 345 – 415 MPa (50 – 60 ksi) | 105 – 135 MPa (15 – 20 ksi) | 275 – 345 MPa (40 – 50 ksi) |

| Corrosion Resistance | Good (General use) | Good (Stress corrosion resistant) | Fair (Prone to stress corrosion cracking) | Excellent (Marine environments) | Good (General use) |

| Fatigue Resistance | Good | Excellent | Good | Good | Good |

| Heat Treatability | High | High | High | Limited | High |

| Workability | Excellent | Moderate | Moderate | Good | Moderate |

| Weldability | Excellent | Moderate | Fair | Good | Moderate |

| Applications | Aerospace, automotive, construction, manufacturing | Aerospace, military, high-stress automotive | Aerospace, structural components | Marine, automotive, tanks | Aerospace, sports equipment, structural components |

- 6061 Aluminum Coil: Known for its good balance of strength, workability, and corrosion resistance. It is versatile and used in a wide range of applications including aerospace, automotive, and construction. It is highly weldable and can be heat-treated to enhance its properties.

7075 Aluminum Coil: Offers higher strength and fatigue resistance compared to 6061, making it suitable for high-performance applications such as aerospace and military. It is less workable and weldable but has excellent stress corrosion resistance.

2024 Aluminum Coil: Provides high strength and good fatigue resistance, primarily used in aerospace applications. However, it is more prone to stress corrosion cracking compared to 6061.

5052 Aluminum Coil: Known for its excellent corrosion resistance, especially in marine environments, but has lower strength compared to 6061 and is less heat-treatable.

7005 Aluminum Coil: Similar to 6061 in terms of strength and fatigue resistance, with applications in aerospace and sports equipment. It is less workable and weldable compared to 6061 but has good general corrosion resistance.

How Can I Get A Sample Of 6061 Aluminum Coils?

Please contact us directly and send us the material, specification, quantity, and delivery address of the samples you need.

Features of 6061 Aluminum Coil:

Alloy Series: 6000 Series

High Strength: Tensile strength of 240 – 310 MPa (35 – 45 ksi) and yield strength of 155 – 270 MPa (22 – 39 ksi).

Excellent Workability: Easy to machine, cut, and form.

Good Corrosion Resistance: Suitable for marine and industrial environments.

Heat Treatable: Can be heat-treated for enhanced strength (common tempers include T6 and T651).

Good Weldability: Can be welded using standard techniques.

Moderate Thermal Conductivity: Useful in heat exchangers and thermal applications.

Lightweight: High strength-to-weight ratio.

Versatile Applications: Used in aerospace, automotive, construction, and manufacturing.

Surface Finish: This can be anodized or polished for improved appearance and durability.