As one of the leading 3105 Aluminum Coil suppliers and 3105 Aluminum Coil manufacturers in China, we are committed to providing first-class products that meet industry standards. Our 3105 Aluminum Coil features excellent formability, good corrosion resistance, and cost-effectiveness, making it ideal for residential exteriors, roof panels, and more.

Looking for competitive 3105 Aluminum Coil prices? We offer the most attractive prices on the market, ensuring you get the best value for your investment. With a comprehensive 3105 Aluminum Coil inventory, we guarantee timely supply and fast delivery to keep your project on track.

Looking for 3105 aluminum coil suppliers? Contact us today for a free quote and competitive pricing. We provide high-quality 3105 aluminum coil for sale with prompt delivery worldwide.

3105 Aluminium Coil Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H46, etc.

Thickness: 0.2~300mm

Width: 500~2500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

Looking for Reliable 3105 Aluminum Coil Suppliers? Send Us Your Inquiry Today!

3105 Aluminum Coil Data Sheet

Chemical Composition of 3105 Aluminum Coil

| Al | Mn | Cu | Fe | Si | Mg | Zn | Other Elements |

|---|---|---|---|---|---|---|---|

| Balance | 0.3 – 0.9% | 0.0 – 0.20% | 0.0 – 0.7% | 0.0 – 0.3% | 0.0 – 0.2% | 0.0 – 0.2% | Each ≤ 0.05%, Total ≤ 0.15% |

There are some differences in the chemical composition of aluminum products from different aluminum manufacturers, but they are all within a certain range. If you want to know more, please contact us directly!

Mechanical Properties of 3105 Aluminum Coil

| Temper | Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|---|

| O (Annealed) | 130 – 160 MPa (19 – 23 ksi) | 100 – 130 MPa (15 – 19 ksi) | ~20% | ~30 Brinell |

| H14 (Work-Hardened) | 150 – 180 MPa (22 – 26 ksi) | 120 – 150 MPa (17 – 22 ksi) | ~10% | ~50 Brinell |

| H16 (Work-Hardened) | 160 – 190 MPa (23 – 28 ksi) | 140 – 160 MPa (20 – 23 ksi) | ~8% | ~60 Brinell |

| H18 (Work-Hardened) | 170 – 200 MPa (25 – 29 ksi) | 150 – 170 MPa (22 – 25 ksi) | ~5% | ~70 Brinell |

Choose us for reliable 3105 Aluminum Coil solutions that meet your specific needs with precision and quality.

Physical Properties of 3105 Aluminum Coil

| Property | Value |

|---|---|

| Density | ~2.73 g/cm³ (0.098 lb/in³) |

| Melting Point | ~655 – 660°C (1211 – 1220°F) |

| Thermal Conductivity | ~160 W/m·K (1100 BTU/hr·ft²·°F/in) |

| Electrical Conductivity | ~30% IACS |

| Specific Heat Capacity | ~900 J/kg·K (0.215 BTU/lb·°F) |

| Young’s Modulus | ~70 GPa (10,000 ksi) |

| Poisson’s Ratio | ~0.33 |

| Coefficient of Thermal Expansion | ~23 x 10⁻⁶ /K (13 x 10⁻⁶ /°F) |

Different Tempers of 3105 Aluminum Coil

| Temper | Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|---|

| O (Annealed) | 130 – 160 MPa (19 – 23 ksi) | 100 – 130 MPa (15 – 19 ksi) | ~20% | ~30 Brinell |

| H14 (Work-Hardened) | 150 – 180 MPa (22 – 26 ksi) | 120 – 150 MPa (17 – 22 ksi) | ~10% | ~50 Brinell |

| H16 (Work-Hardened) | 160 – 190 MPa (23 – 28 ksi) | 140 – 160 MPa (20 – 23 ksi) | ~8% | ~60 Brinell |

| H18 (Work-Hardened) | 170 – 200 MPa (25 – 29 ksi) | 150 – 170 MPa (22 – 25 ksi) | ~5% | ~70 Brinell |

Applications of 3105 Aluminum Coil Metal

Building Panels: 3105 aluminium coil’s resistance to weathering makes it ideal for use in building panels, including siding and roofing materials, offering durability and aesthetic flexibility.

Automotive Body Panels: The coil is used in automotive applications due to its lightweight nature and ability to resist corrosion, which is crucial for vehicle longevity and performance.

Home Appliances: Its excellent workability and resistance to various chemicals make it a popular choice for manufacturing home appliances like refrigerators and washing machines.

HVAC Systems: In air conditioning and HVAC systems, the 3105 al coil is favored for its thermal conductivity and resistance to corrosion, ensuring long-lasting performance in harsh environments.

Packaging: 3105 aluminum is used in aluminum foil applications, which benefit from its ability to provide a protective barrier against moisture and light.

Cookware: The alloy’s good thermal conductivity and non-reactive properties make it suitable for use in cookware, where efficient heat distribution and resistance to food reactions are important.

Electrical Covers: Its electrical properties and lightweight nature are beneficial for use in various electrical housings and components.

Marine Components: The alloy’s resistance to saltwater corrosion makes it suitable for marine environments, including boat parts and other maritime applications.

Decorative Finishes: Its ability to be easily formed and finished makes it ideal for decorative uses in architecture, including trims and accents.

If you are looking for a 3105 Aluminum Coil manufacturer that offers the best 3105 Aluminum Coil prices, we provide high-quality 3105 Aluminum Coil for sale with professional services and large stock for fast delivery, etc.

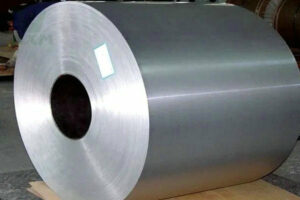

3105 Aluminum Coil Packages

The following is our company’s standard aluminum coil export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 3105 Aluminum Coil?

3105 aluminum coil is an aluminum alloy known for its excellent strength, formability, and corrosion resistance. It belongs to the 3000 series of aluminum alloys primarily alloyed with manganese.

3000 Series Aluminum

As a top 3105 Aluminum Coil Supplier, we offer high-quality products tailored to various industrial and commercial applications. Whether you are looking for 3105 Aluminum Coil for Sale, need customized dimensions, or want to compare 3105 Aluminum Coil Prices, we provide competitive solutions for global customers, including those in North America, South America, and Europe.

3105 Aluminum Coil VS Other Aluminum Coil:

| Property | 3105 Aluminum Coil | 3003 Aluminum Coil | 5052 Aluminum Coil | 6061 Aluminum Coil |

|---|---|---|---|---|

| Alloy Series | 3000 Series | 3000 Series | 5000 Series | 6000 Series |

| Composition | Aluminum + Manganese | Aluminum + Manganese | Aluminum + Magnesium | Aluminum + Magnesium + Silicon |

| Strength | Moderate | Moderate | High | High |

| Corrosion Resistance | Good | Good | Excellent | Moderate |

| Weldability | Good | Good | Excellent | Good |

| Formability | Good | Excellent | Good | Excellent |

| Machinability | Good | Good | Good | Excellent |

| Density | 2.71 g/cm³ | 2.73 g/cm³ | 2.68 g/cm³ | 2.70 g/cm³ |

| Tensile Strength | ~165 MPa | ~130 MPa | ~250 MPa | ~310 MPa |

| Yield Strength | ~110 MPa | ~120 MPa | ~200 MPa | ~270 MPa |

| Typical Applications | Residential siding, roofing panels, rain-carrying goods, decorative components | Roofing sheets, automotive parts, industrial uses | Marine, automotive parts, fuel tanks, building cladding | Aerospace, structural components, automotive parts |

How Can I Get A Sample Of 3105 Aluminum Coils?

Please contact us directly and send us the material, specification, quantity and delivery address of the samples you need.

Features of 3105 Aluminum Coil:

Alloy Series: 3000 Series

Composition: Primarily aluminum with manganese as the main alloying element, and small amounts of other elements such as iron and copper.

Strength: Provides moderate strength, making it suitable for various applications where high strength is not the primary requirement.

Corrosion Resistance: Offers good corrosion resistance, particularly in atmospheric environments, which makes it suitable for use in outdoor and exposed applications.

Formability: Exhibits good formability and can be easily shaped and processed, allowing for a wide range of manufacturing applications.

Applications: Commonly used in applications such as residential siding, roofing panels, rain-carrying goods, and various decorative and functional components in construction and manufacturing.