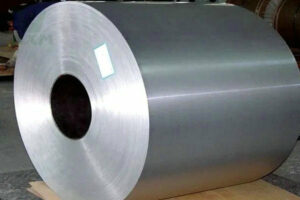

HXM is one of the leading 3005 Aluminum Coil suppliers and manufacturers in China, we specialize in providing high-quality aluminum coils that meet your specific requirements. Our 3005 Aluminum Coil is known for its excellent corrosion resistance, formability, and strength, making it ideal for architectural, automotive, and manufacturing applications.

Looking for competitive 3005 Aluminum Coil prices? We offer the most competitive prices on the market, ensuring you can get a price advantage on your project. Whether you need standard or custom sizes, our company has a large inventory of Aluminum Coil to ensure you find the right one for your project.

3005 Aluminium Coil Specifications

Temper: O, F, H12, H14, H16, H18, H19, H22, H24, etc.

Thickness: 0.2~300mm

Width: 500~2500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

Standards: ASTM B209 / ASME SB209 / EN BS 485/ EN BS 573 / JIS H4000 / GB/T 3880-2006/ GB/T 3190-2008, etc.

3005 Aluminum Coil Data Sheet

Equivalent Grades Of Aluminum 3005 Coil

| Standard | Alloy Designation |

|---|---|

| AA (Aluminum Association, USA) | 3005 |

| UNS (Unified Numbering System, USA) | A93005 |

| ASTM (American Society for Testing and Materials) | B209, B221 |

| EN (European Standard) | EN AW-3005 |

| ISO (International Organization for Standardization) | AlMn1Mg0.5 |

| JIS (Japanese Industrial Standards) | A3005 |

| GB (Chinese National Standard) | 3005 |

| DIN (German Standard) | AlMn1Mg0.5 |

Chemical Composition of 3005 Aluminum Coil

| Element | Al | Mn | Mg | Cu | Fe | Si | Zn | Cr | Other, each | Other, total |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 96.8 – 98.6 | 1.0 – 1.5 | 0.2 – 0.6 | ≤ 0.30 | ≤ 0.7 | ≤ 0.6 | ≤ 0.25 | ≤ 0.1 | ≤ 0.05 | ≤ 0.15 |

Notes:

Al: The remainder of the composition is aluminum.

Mn: Added to increase strength and hardness.

Mg: Improves the strength and workability.

Cu, Fe, Si, Zn, Cr: Present in controlled amounts to enhance specific properties and performance characteristics.

Other elements: Trace amounts of other elements are present, each limited to 0.05%, and the total cannot exceed 0.15%.

Mechanical Properties and Tempers of 3005 Aluminium Coil

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

| H12 | 130 – 170 | 90 – 110 | 12 – 14 | ~45 HB |

| H14 | 140 – 185 | 100 – 125 | 10 – 12 | ~46 HB |

| H16 | 150 – 195 | 110 – 135 | 8 – 10 | ~47 HB |

| H18 | 160 – 205 | 120 – 145 | 8 – 9 | ~48 HB |

| H22 | 130 – 175 | 95 – 115 | 12 – 14 | ~45 HB |

| H24 | 140 – 185 | 105 – 130 | 10 – 12 | ~46 HB |

| H26 | 150 – 195 | 115 – 140 | 8 – 10 | ~47 HB |

| H28 | 160 – 205 | 125 – 150 | 8 – 9 | ~48 HB |

| H32 | 130 – 170 | 90 – 115 | 12 – 14 | ~45 HB |

| H34 | 140 – 185 | 100 – 125 | 10 – 12 | ~46 HB |

| H36 | 150 – 195 | 110 – 135 | 8 – 10 | ~47 HB |

| H38 | 160 – 205 | 120 – 145 | 8 – 9 | ~48 HB |

For high-quality 3005 aluminum coil and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 3005 Aluminum Coil

Strain-Hardened (H12, H14, H16, H18): These tempers involve increasing hardness through cold working. The numbers indicate the degree of strain hardening, with H18 being the hardest.

Strain-Hardened and Partially Annealed (H22, H24, H26, H28): These tempers involve a combination of strain hardening and partial annealing to improve formability while retaining some hardness.

Strain-Hardened and Stabilized (H32, H34, H36, H38): These tempers provide stability in mechanical properties, combining strain hardening with stabilization treatments to enhance strength and durability.

As a leading 3005 Aluminum Coil manufacturer, Huaxiao Metal offers competitive pricing and a large inventory. Prices may vary depending on specifications, order quantity, and global market conditions. Contact us today for the latest 3005 Aluminum Coil prices and get a custom service.

Applications of 3005 Aluminum Coil Metal

Construction and Architecture:

Roofing Sheets: Often used in roofing applications for residential and commercial buildings due to their durability and resistance to weathering.

Curtain Walls and Cladding: Employed in building facades and curtain walls for their aesthetic appeal and ability to withstand environmental exposure.

Gutters and Downspouts: Used in the production of gutters and downspouts, benefiting from its corrosion resistance and ease of fabrication.

Automotive Industry:

Interior Panels: Utilized for manufacturing interior panels and trim components in vehicles, where its formability and lightweight properties are advantageous.

Exterior Components: Applied in exterior automotive parts, including moldings and trims, due to its resistance to environmental factors and ease of processing.

Manufacturing:

Packaging Materials: Used in the production of aluminum foil and packaging materials, especially for food and beverage containers, due to its good barrier properties and durability.

Heat Exchangers: Employed in the manufacturing of heat exchangers and radiators, benefiting from their thermal conductivity and resistance to corrosion.

Household Appliances:

Appliance Panels: Used in the production of panels and components for household appliances such as refrigerators, washing machines, and air conditioners, due to its appearance and strength.

Decorative Trim: Applied in decorative trim and detailing for various home appliances, enhancing both functionality and aesthetics.

Industrial Applications:

HVAC Systems: Commonly used in the production of components for HVAC systems, including air conditioning units and ventilation systems, where its corrosion resistance and formability are critical.

Ductwork: Employed in manufacturing ductwork and other industrial components, benefiting from its ease of fabrication and resistance to environmental factors.

Marine and Transportation:

Marine Components: Occasionally used in marine applications where moderate corrosion resistance is required, though it is less common compared to alloys with higher resistance.

Transport Containers: Applied in the construction of transport containers and shipping materials for their strength and durability.

Looking for a reliable 3005 Aluminum Coil supplier? Send us your requirements and our team will provide you with the best pricing and shipping options!

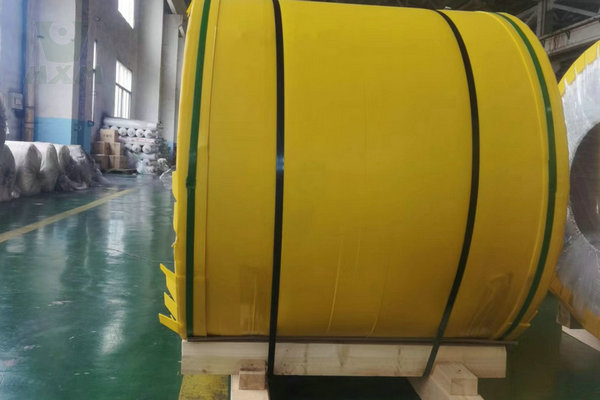

3005 Aluminum Coil Packages

The following is our company’s standard aluminum coil export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 3005 Aluminum Coil?

3005 aluminum coil is a member of the 3000 series of aluminum alloys, which are known for their excellent corrosion resistance, good formability, and moderate strength. It is primarily composed of aluminum, manganese, and a small amount of other elements, which contribute to its properties.

3000 Series Aluminum

3005 Aluminum Coil VS Other Aluminum Coil:

| Property | 3005 Aluminum Coil | 3003 Aluminum Coil | 5052 Aluminum Coil | 6061 Aluminum Coil |

|---|---|---|---|---|

| Alloy Series | 3000 Series | 3000 Series | 5000 Series | 6000 Series |

| Strength | Moderate | Moderate | High | High |

| Corrosion Resistance | Good | Good | Excellent | Moderate |

| Formability | Excellent | Excellent | Good | Excellent |

| Workability | Good | Good | Good | Excellent |

| Weldability | Good | Good | Excellent | Good |

| Density | 2.73 g/cm³ | 2.73 g/cm³ | 2.68 g/cm³ | 2.70 g/cm³ |

| Tensile Strength | ~130 MPa | ~130 MPa | ~250 MPa | ~310 MPa |

| Yield Strength | ~110 MPa | ~120 MPa | ~200 MPa | ~270 MPa |

| Typical Applications | Roofing, siding, gutters, packaging | Roofing, automotive, industrial | Marine, automotive, tanks | Aerospace, structural, automotive |

How Can I Get A Sample Of 3005 Aluminum Coils?

Please contact us directly and send us the material, specification, quantity and delivery address of the samples you need.

Features of 3005 Aluminum Coil:

Alloy Composition: Mainly aluminum with approximately 1.2% manganese and small amounts of other elements.

Corrosion Resistance: Offers good resistance to atmospheric corrosion, making it suitable for outdoor and marine environments.

Formability: Excellent workability and formability, allowing it to be easily shaped and processed.

Strength: Provides moderate strength, which makes it appropriate for applications where high strength is not the primary requirement.

Applications: Commonly used in applications such as roofing sheets, siding, gutters, downspouts, and packaging materials due to its durability and ease of fabrication.