5052 Aluminum Alloy Manufacturers & Suppliers

5052 aluminum alloy is a high-performance aluminum-magnesium alloy known for its excellent corrosion resistance, outstanding strength, and excellent machinability. As a widely used alloy, it is suitable for marine, automotive, construction, and other demanding industries.

At Huaxiao Metal, we specialize in providing high-quality 5052 aluminum alloys to meet the needs of different industries. Whether you are looking for a 5052 aluminum alloy supplier or a competitive 5052 aluminum alloy price, we can be one of your trusted partners.

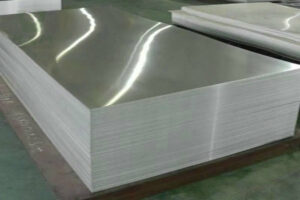

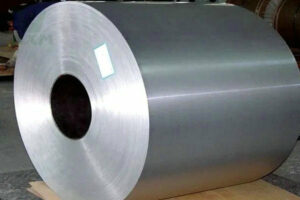

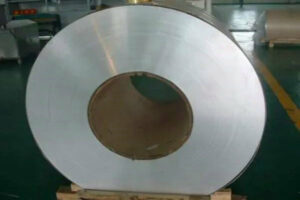

5052 Aluminum Alloy Shapes and Forms

Huaxiao Metal is a leading 5052 aluminum alloy manufacturer and supplier, offering:

- Large inventory of 5052 aluminum alloy in various forms and sizes.

- Custom sizes and surface treatments to meet specific project requirements.

- International shipping ensures timely delivery around the world.

Whether you need 5052 aluminum alloy sheets, plates, or coils, we have the capabilities to fulfill your order.

5052 Aluminum Alloy Data Sheet

5052 Aluminium Equivalent Table

| Standard | Equivalent Alloy Designation |

|---|---|

| ASTM | 5052 |

| ISO | AlMg2.5 |

| DIN | AlMg2.5 (3.3523) |

| EN | AW-5052 |

| UNS | A95052 |

Chemical Composition of 5052 Aluminum

| Element | Content (%) |

|---|---|

| Mg | 2.2 – 2.8 |

| Cr | 0.15 – 0.35 |

| Mn | ≤ 0.10 |

| Si | ≤ 0.25 |

| Fe | ≤ 0.40 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Al | Balance |

Mechanical Properties of 5052 Aluminum With Different Tempers

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| O (Annealed) | 193 – 228 | ~90 | 12 – 20 |

| H32 | 215 – 265 | 130 – 195 | 5 – 12 |

| H34 | 240 – 290 | 180 – 240 | 3 – 10 |

| H36 | 250 – 300 | ~200 | 2 – 8 |

| H38 | 270 – 320 | ~230 | 1 – 6 |

Physical Properties of 5052 Aluminium

| Property | Value |

|---|---|

| Density | 2.68 g/cm³ |

| Melting Point | 607 – 650°C |

| Thermal Conductivity | ~138 W/m·K |

| Electrical Conductivity | ~35% IACS |

| Coefficient of Thermal Expansion | 23.8 µm/m·K |

5052 Aluminum Tempers

| Temper | Characteristics |

|---|---|

| O | Soft and ductile, easy to form and weld. |

| H32 | Medium strength, good corrosion resistance, and weldability. |

| H34 | Higher strength, suitable for structural applications. |

| H36 | Increased strength, and reduced formability. |

| H38 | Maximum strength, minimal elongation, and highest rigidity. |

5052 Aluminum Application

Marine Industry: Ideal for shipbuilding and offshore structures due to excellent corrosion resistance.

Automotive: Used in fuel tanks, panels, and other lightweight components.

Construction: Suitable for roofing, siding, and decorative structures.

Packaging: Commonly used in food and chemical storage containers.

FAQ

What is the 5052 aluminum?

5052 aluminum is a widely used aluminum-magnesium alloy in the 5000 series, known for its excellent corrosion resistance, medium-to-high strength, and superior machinability. It is often used in industries that require a durable yet lightweight material to withstand harsh environments, such as marine, automotive, and aerospace applications.

5052 aluminum is a reliable material that combines performance, cost-effectiveness, and durability, making it a must-have choice for manufacturers. If you have specific project needs, feel free to ask!

Is 5052 Aluminum Bendable?

Yes, 5052 aluminum is highly bendable and one of the most formable aluminum alloys. Its excellent ductility and flexibility make it suitable for applications that require bending or shaping. Key factors influencing its bendability include:

- Temper: The O (annealed) temper offers the best bendability, while harder tempers like H34 or H36 may require careful handling to avoid cracking.

- Bend Radius: A larger bend radius reduces the risk of cracking during the bending process.

- Direction of Grain: Bending perpendicular to the grain structure minimizes the likelihood of cracking.

5052 aluminum is commonly used in marine, automotive, and architectural industries where forming into complex shapes is required.

Is 5052 Aluminum Weldable?

Yes, 5052 aluminum is highly weldable and compatible with most common welding methods, including:

- TIG (Tungsten Inert Gas) Welding

- MIG (Metal Inert Gas) Welding

Key points about its weldability:

- Corrosion Resistance After Welding: Retains excellent corrosion resistance in marine and industrial environments.

- Filler Material: Common fillers like 5356 or 4045 are used to ensure strong and durable welds.

- Post-Welding Strength: While welding may reduce the material’s strength in the heat-affected zone (HAZ), 5052 retains adequate performance for most applications.

5052 aluminum’s weldability makes it a preferred choice for manufacturing fuel tanks, pressure vessels, and marine components.

If you need more technical details or have specific use cases, feel free to ask!

Can I order 5052 Aluminum in custom sizes?

Yes, we provide custom cutting, shaping, and finishing options to match your needs.

What industries commonly use 5052 Aluminum Alloy?

It is widely used in marine, automotive, construction, and packaging industries due to its durability and versatility.

What is the difference between 5052 and 6061 aluminum alloy?

5052 offers better corrosion resistance, while 6061 has higher strength and is more suitable for structural applications.

5052 Aluminum vs 6061 Aluminum

Contact Us For The 5052 Aluminum Prices

Complete your project with outstanding quality 5052 aluminum alloy from Huaxiao Metal. Contact us today to discuss your needs, compare prices, and more.