When it comes to metal materials, aluminum alloy is the most common one, and it is widely used in construction, automotive, aviation, electronics, and packaging. Not only is it a commonly used material, but it is also a very useful one because of its many excellent properties.

Therefore, knowing the main properties of aluminum is very important to understand its use in various fields of application. This article discusses the main properties of aluminum, including its physical, chemical, mechanical and process properties, and explores the importance of aluminum in different application areas.

What are the Physical Properties of Aluminum?

Aluminum alloy is a silvery-white metal with good luster and electrical conductivity. Its density is relatively low, about one-third that of steel, at about 2.7 grams per cubic centimeter. Aluminum has a relatively low melting point of around 660°C, making it relatively easy to machine and shape. Aluminum has a high thermal conductivity, and it is a good heat spreader material. In addition, aluminum is also very reflective and corrosion-resistant, which makes it ideal for use in construction, automotive, and other applications.

The physical properties of aluminum play an important role in its use in different fields, for example, its low density makes it an ideal choice in the manufacture of automotive lightweight parts, while in construction it is highly reflective Its strong and corrosion-resistant properties make it a popular building material.

What are the Chemical Properties of Aluminum Alloy?

Aluminum alloy is stable at room temperature, but it reacts easily with oxygen in the air to form a protective layer of aluminum oxide, which protects the aluminum from further oxidation and corrosion. In addition, aluminum can also react with acids and bases, but its reactivity is relatively low compared to other metals. Aluminum also has good electrochemical properties, which makes it widely used in electronics, aerospace, and other high-tech fields.

Aluminum’s corrosion resistance makes it a popular construction material, and its chemical properties can be altered by alloying it with other elements to suit different application needs. For example, alloying aluminum with elements such as magnesium, manganese, and silicon increases its strength and hardness while maintaining good corrosion resistance. Chemical properties also play an important role in the use of aluminum in different application areas, for example, in automobile and aircraft construction, alloyed aluminum can provide sufficient strength and hardness for safety and reliability.

Aluminum Mechanical Properties

Aluminum alloy has good mechanical properties including strength, toughness, and ductility. Although aluminum has relatively low strength, it has excellent toughness and plasticity, which means it can deform without breaking when subjected to external forces. This makes aluminum an ideal material for a wide variety of components such as aerospace and automotive parts, construction materials and packaging containers, among others.

In addition, aluminum also has good fatigue resistance and corrosion resistance, and these properties make aluminum a popular material for manufacturing various mechanical parts. Mechanical properties play an important role in the use of aluminum in different application areas, for example, in aerospace and automobile manufacturing, aluminum’s high strength and excellent toughness can make aircraft and cars safer and more reliable.

Aluminum Process Characteristics

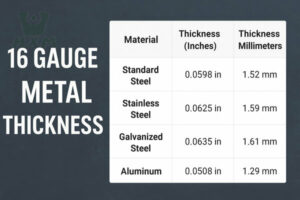

Aluminum alloy has good technological properties, including malleability, stretchability, compressibility, machinability, and weldability. Aluminum can be formed in a variety of ways including cold rolling, hot rolling, drawing, extruding, and forging, making it an ideal material for making a wide variety of parts and products. In addition, the weldability of aluminum is also very good, it can be connected by a variety of welding methods, such as argon arc welding, TIG welding, MIG welding, etc., which makes aluminum easier to be processed and manufactured.

Technological properties play an important role in the use of aluminum in different application areas, for example, in the field of construction, aluminum’s compressibility and malleability make it an ideal building material for the manufacture of various complex architectural forms. In aerospace and automotive manufacturing, aluminum’s machinability and weldability make it an ideal material for creating a variety of complex parts and structures to improve the performance and efficiency of aircraft and automobiles.

Application of Aluminum

Aluminum’s excellent physical, chemical, mechanical and technological properties make it useful in a wide variety of applications. The following are the main applications of aluminum in different fields:

Construction Field

Automotive Manufacturing

Aerospace

Packaging

Electronic Field

In conclusion, the key properties of aluminum make it useful in a variety of applications ranging from construction, automotive and aerospace to packaging and electronics. With the continuous advancement of technology and the continuous development of material science, aluminum will be widely used in more fields.

In Conclusion

Aluminum is a very useful material with excellent physical, chemical, mechanical, and technological properties. It is widely used in various application fields such as construction, automotive, aerospace, packaging, and electronics. Aluminum’s low density, high strength, corrosion resistance, and machinability make it an ideal lightweight material that can improve product performance and efficiency.

With the continuous advancement of technology and the continuous development of material science, aluminum will be widely used in more fields. Therefore, understanding the main properties and application fields of aluminum is very important for engineers, manufacturers, and consumers.