3003 aluminum plate is one of the most widely used aluminum alloys in the industrial and construction sectors. Known for its excellent corrosion resistance, good workability, and moderate strength, 3003 aluminum is commonly used in roofing, siding, HVAC systems, and various transportation applications.

At Huaxiao Metal, we specialize in supplying high-quality 3003 aluminum plates in various thicknesses and sizes, suitable for diverse industrial requirements. This guide aims to answer common questions, explain the material properties, and help you select the right aluminum plate for your project.

Looking for a quote on 3003 aluminum plate right away?

3003 Aluminum Plate Introduction

In modern industrial production, aluminum plate is a very important material. Among them, the 3003 aluminum plate is a common aluminum alloy plate, widely used in aviation, automotive, construction, and other fields. The following is the introduction and analysis of the 3003 aluminum plate.

3003 Basic Information of Aluminum Plate

3003 aluminum plate is a copper alloy aluminum plate; its copper content is about 0.05-0.20%. The aluminum sheet has good workability and corrosion resistance, as well as excellent bending strength and strength-to-weight ratio.

Unlike the 6xxx or 7xxx series alloys, 3003 aluminum is not heat-treatable. Its strength is developed through strain hardening (cold working), designated by “H” tempers like H14 or H24.

3003 Application Field of Aluminum Plate

Because the 3003 aluminum plate has good processing performance and corrosion resistance, it is widely used in aviation, automobile, construction and other fields. In the aviation sector, 3003 aluminum plates are commonly used for components such as aircraft shells and wings. In the automotive sector, the aluminum plate is used to make the body and frame. In the construction field, 3003 aluminum is often used to manufacture building materials such as roofs and wallboards.

3003 Processing Performance of Aluminum Plate

3003 aluminum sheet has good machinability. It can be processed by various processing methods, such as cold processing, hot processing, drawing, die casting, etc. In addition, it can also be surface-treated to meet different needs.

3003 Processing Technology of Aluminum Plate

When processing 3003 aluminum sheets, it is necessary to use appropriate processing technology. Generally speaking, the aluminum sheet can be processed by rolling, drawing, molding, etc. At the same time, it is also necessary to pay attention to avoid excessive processing so as not to affect the performance of the aluminum sheet.

Chemical Composition

The chemical composition of 3003 aluminum plate is standardized by ASTM B209 and includes the following elements:

| Element | Typical Range (%) |

|---|---|

| Aluminum (Al) | Balance |

| Manganese (Mn) | 1.0–1.5 |

| Copper (Cu) | ≤ 0.10 |

| Iron (Fe) | ≤ 0.70 |

| Silicon (Si) | ≤ 0.60 |

| Zinc (Zn) | ≤ 0.10 |

| Other elements | ≤ 0.05 each |

This composition gives 3003 aluminum excellent corrosion resistance while maintaining good workability.

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 130–180 MPa |

| Yield Strength | 55–95 MPa |

| Elongation | 12–25% |

| Hardness (Brinell) | 40–60 HB |

3003 aluminum plate is moderately strong and exhibits good ductility, making it suitable for bending, drawing, and forming without cracking.

Physical Properties

| Property | Value |

|---|---|

| Density | 2.73 g/cm³ |

| Melting Point | 643–654 °C |

| Thermal Conductivity | 130–150 W/m·K |

| Coefficient of Thermal Expansion | 23.2 µm/m·K |

| Electrical Conductivity | 17–18% IACS |

These physical properties make 3003 aluminum ideal for applications in heat exchangers, roofing, and exterior panels where corrosion resistance and lightweight properties are critical.

3003 Advantages and Disadvantages of Aluminum Plate

3003 aluminum has many advantages, such as good processability, corrosion resistance, and a good strength-to-weight ratio. At the same time, the price of the aluminum plate is relatively reasonable. In addition, it also has good weldability and can be processed and manufactured by various welding methods.

However, the aluminum plate also has some disadvantages, such as relatively low tensile strength.

3003 Density of Aluminum Plate

What is the density of the 3003 aluminum plate? It has a density of about 2.73g/cm³. Compared with other materials, the 3003 aluminum plate has a lower density, so it is relatively lightweight and easy to process and transport.

3003 Environmental Protection of Aluminum Plate

3003 aluminum plate is an environmentally friendly material. It can be recycled and reused to reduce environmental pollution. Compared with other materials, its production process is less exhaust gas and wastewater, in line with environmental protection requirements.

Hardness and Strength

3003 aluminum plate is available in multiple tempers: H14, H24, and H18. The temper affects hardness and mechanical performance:

H14: Strain-hardened, moderately hard, suitable for forming

H24: Strain-hardened and partially annealed, moderate hardness

H18: Fully hard, higher strength, limited formability

Tip: Choosing the correct temper depends on your application—bending and forming require softer tempers, while structural panels may require harder tempers.

3003 Hareness of Aluminum Plate

The Basics

The hardness of the 3003 aluminum plate refers to the external force it can withstand, usually measured by a hardness meter. The hardness value of the 3003 aluminum plate is usually between 40-50HB, which is a relatively medium hardness. In addition, the 3003 aluminum plate has good weldability and workability, corrosion resistance is also strong.

3003 Hardness Comparison of Aluminum Plate

Compared with 6061, 5052, 5083, and other aluminum alloys with aluminum plates, the hardness of 3003 aluminum plates is slightly lower. However, the 3003 aluminum plate is better than other aluminum alloys in terms of corrosion resistance and processability, so in some areas that require high corrosion resistance, such as food processing, and chemical industry, the 3003 aluminum plate is more popular.

3003 Factors Affecting the Hardness of the Aluminum Plate

The hardness of the 3003 aluminum plate is affected by many factors, such as the thickness of the aluminum plate, cold processing, and hot processing, among which the main factors are the different heat treatment processes and states used. Different heat treatment processes and states will have a great impact on the hardness of the 3003 aluminum plate.

3003 Method for Improving the Hardness of the Aluminum Plate

To improve the hardness of the 3003 aluminum plate, the following methods can be used:

First, the use of an appropriate heat treatment process, such as T6, T651, and other heat treatment states, can significantly improve the hardness of the 3003 aluminum plate;

second is to increase the thickness of the aluminum plate, which can increase the bearing capacity of the aluminum plate, thereby increasing the hardness;

Third, the use of cold processing processes, such as rolling, stretching, etc., can reduce the grain size of the aluminum plate, thereby increasing the hardness.

3003 Application of Aluminum Hardness

Because the 3003 aluminum plate has good machinability and corrosion resistance, it has been widely used in food processing, chemical industry, construction, electronics, and other fields. Among them, in the manufacture of pressure vessels, heat exchangers, and other high-strength requirements, it is necessary to use T6, T651, and other heat treatment states of the 3003 aluminum plate to meet its high-strength requirements.

3003 Development Trend of Aluminum Plate Hardness

With the continuous development of technology and the continuous expansion of application, the hardness of the 3003 aluminum plate is also constantly improving, and at the same time, it is necessary to maintain its good machinability and corrosion resistance. In the future, the improvement of the hardness of the 3003 aluminum sheet will become one of the focuses of development.

3003 Webster's Hareness of Aluminum Plate

3003 Overview of the Hardness of Aluminum Plate

3003 aluminum alloy is a commonly used aluminum-manganese alloy with good weldability, corrosion resistance, and formability. In practical applications, Wechsler hardness is one of the important indicators to measure the hardness of aluminum plates, and the Wechsler hardness of 3003 aluminum plates is usually between 40-60. The Wechsler hardness of 3003 aluminum plates produced by different manufacturers will also be different, so when choosing 3003 aluminum plates, you need to pay attention to the corresponding Wechsler hardness value.

Factors Affecting the Hardness of 3003 Aluminum Plate

In addition to the different Wechsler hardness of 3003 aluminum plates produced by different manufacturers, its Wechsler hardness will also be affected by the following factors:

Processing technology: Different processing processes will have different effects on the Wechsler hardness of 3003 aluminum plates, such as cold rolling, hot rolling, cold drawing, etc.

Heat treatment: Heat treatment can change the structure of a 3003 aluminum plate, and then affect its Wechsler hardness.

Alloying elements: 3003 aluminum alloy contains different alloying elements, such as manganese, aluminum, copper, etc., which will also have a suggested impact on the hardness of the aluminum plate.

Method for Testing the Hardness of 3003 Aluminum Plate

There are two common methods for testing the hardness of 3003 aluminum plate Wechsler: one is a macro hardness tester, and the other is a microhardness tester. The macro hardness tester is suitable for testing larger specimens, while the micro hardness tester is suitable for testing small specimens. When testing the hardness of the 3003 aluminum plate, it is necessary to pay attention to factors such as the environment and temperature during the test to ensure the accuracy of the test results.

3003 Application Field of Aluminum Plate

Because the 3003 aluminum plate has good weldability, corrosion resistance, and formability, it has a wide range of applications in construction, automotive, electronics, aviation, and other fields. In these fields, the Wechsler hardness of 3003 aluminum plate is also widely concerned, because hardness is one of the important indicators that determine the service life and scope of use of aluminum plate.

How to Improve the Hardness of 3003 Aluminum Plate

The Wechsler hardness of the 3003 aluminum plate can be improved from the following aspects:

Optimize the production process: By optimizing the production process, the organizational structure of the 3003 aluminum plate can be improved, and then the Wechsler hardness can be increased.

Adding alloying elements: Adding the recommended amount of alloying elements, such as silicon, manganese, etc., can improve the hardness of the 3003 aluminum plate.

The use of heat treatment process: the appropriate heat treatment process can improve the hardness of the 3003 aluminum plate.

In summary, the Wechsler hardness of the 3003 aluminum plate is usually between 40-60, and its Wechsler hardness will be affected by factors such as the production process, heat treatment, alloying elements, and so on. The methods for testing the hardness of the 3003 aluminum plate are macro hardness tester and microhardness tester. In practical applications, the 3003 aluminum plate corresponding to the Wechsler hardness value needs to be selected to ensure its service life and range of use.

At the same time, the Wechsler hardness of the 3003 aluminum plate can be improved by optimizing the production process, adding alloying elements, and adopting a heat treatment process.

What are the Key Properties of 3003-H14 Aluminum?

For engineers, the data is what matters. Here are the typical mechanical and physical properties for 3003-H14, the most common temper.

| Property | Value (Typical) |

| Tensile Strength | 145 – 186 MPa (21 – 27 ksi) |

| Yield Strength | 145 MPa (21 ksi) |

| Elongation at Break | 8 – 12% |

| Hardness, Brinell | 40 HBW |

| Density | 2.73 g/cm³ (0.0986 lb/in³) |

| Thermal Conductivity | 193 W/m-K |

| Machinability | Fair |

| Formability / Workability | Excellent |

| Weldability | Excellent |

| Corrosion Resistance | Excellent |

Difference Between 3003 and 3004

Aluminum alloys 3003 and 3004 have similar chemical composition and physical properties, but there are still some significant differences between them.

Chemical Composition

Aluminum alloys 3003 and 3004 have slightly different chemical compositions. The main component of 3003 alloys is aluminum, accounting for more than 98%, while also containing a small amount of copper silicon, and other elements. The aluminum content of 3004 alloys is also more than 98%, but it also contains 0.8% magnesium and 0.3% silicon.

Physical Properties

Aluminum alloys 3003 and 3004 are also different in physical properties. Alloy 3003 has a high coefficient of thermal expansion and a low melting point, and has good plasticity and corrosion resistance. The coefficient of thermal expansion of 3004 alloys is slightly lower than that of 3003, but the melting point is slightly higher, and it also has better wear resistance and corrosion resistance.

Application Scope

Due to the different physical and chemical properties of aluminum alloys 3003 and 3004, they are also different in practical applications. 3003 alloy is commonly used in the manufacture of containers, pipes, fuel tanks, and other lightweight products. The 3004 alloy is more suitable for the manufacture of some products that require higher corrosion and wear resistance, such as automobile shells, decorative panels, etc.

Price Differences

Aluminum alloy 3003 and 3004 prices are also different. Because 3004 alloy contains a higher proportion of magnesium and silicon elements, its manufacturing cost is relatively high, so the price is also slightly higher than 3003 alloy.

Degree of Processing Difficulty

Aluminum alloys 3003 and 3004 are also different in the degree of processing difficulty. Because 3003 alloy has good plasticity and toughness, it is easier to handle in the processing and forming process. While 3004 alloy is more brittle, it needs to be more careful when handling, and the processing difficulty is relatively high.

Service Life

The service life of aluminum alloy 3003 and 3004 is also different. Alloy 3003 has good corrosion and wear resistance, so the service life is relatively long. The 3004 alloy also has a longer service life because it contains special elements such as magnesium.

In summary, although aluminum alloys 3003 and 3004 have similar chemical composition and physical properties, there are still obvious differences between them. Therefore, when choosing the right aluminum alloy material, it is necessary to conduct comprehensive consideration and evaluation according to actual needs and requirements.

Difference Between 3003 and 1060

Among the varieties of aluminum plates, 1060 and 3003 aluminum plates are the two most common types. Although they are all aluminum plates, they have obvious differences in material, performance, use, and so on. This article will introduce the difference between 1060 and 3003 aluminum plates from the following six aspects.

Material

1060 aluminum plate is a pure aluminum plate, due to a purity of up to 99.6%, so it has good electrical conductivity, thermal conductivity, plasticity, and other characteristics. The 3003 aluminum plate is an alloy plate composed of aluminum, manganese, and a small amount of copper, so it has higher strength and corrosion resistance.

Use

Because the 1060 aluminum plate has good electrical conductivity, it is usually used in electronic devices, batteries, capacitors, and other fields. The 3003 aluminum plate, because of its higher strength and corrosion resistance, is suitable for manufacturing car body plates, fuel tanks, ships, and other areas with high strength requirements.

Surface Treatment

The surface treatment of 1060 aluminum plate is usually oxidized or tinned to improve its corrosion resistance and aesthetics. The 3003 aluminum plate needs to be anodized to improve its corrosion resistance and the adhesion of the protective layer.

Processing Performance

1060 aluminum plate has good plasticity and processing properties and can be processed by deep drawing, stretching, bending, and other ways. The 3003 aluminum plate is slightly inferior to the 1060 aluminum plate because it contains elements such as manganese and copper.

Price

Because the 1060 aluminum plate is a pure aluminum plate, its price is relatively low. The 3003 aluminum plate is an alloy plate composed of various elements, so the price is relatively high.

Scope of Application

1060 aluminum plate is suitable for some areas with low material requirements, such as the production of aluminum products, daily necessities, etc. The 3003 aluminum plate is suitable for areas with high material strength and corrosion resistance, such as automobiles, ships, and so on.

In summary, although 1060 and 3003 aluminum plates are aluminum plates, they have great differences in material, use, surface treatment, processing performance, price, and application range. Choose a suitable variety of aluminum plates, that can better meet the actual needs.

How Does 3003 Compare to 5052 and 6061 Aluminum?

This is one of the most important questions for material selection.

| Feature | 3003 Aluminum | 5052 Aluminum | 6061 Aluminum |

| Primary Alloy | Manganese (Mn) | Magnesium (Mg) | Magnesium & Silicon (Mg+Si) |

| Strength | Moderate | Higher | Highest (T6 Temper) |

| Corrosion Resistance | Excellent | Excellent (Best in saltwater) | Very Good |

| Formability | Excellent (Best) | Very Good | Good (in annealed state) |

| Weldability | Excellent | Excellent | Good |

| Heat-Treatable? | No | No | Yes |

| Typical Cost | Lowest | Moderate | Higher |

| Best For: | General-purpose sheet metal forming | Marine environments, high-vibration | Structural applications, machining |

Conclusion: Choose 3003 for cost-effective forming. Choose 5052 for higher strength and saltwater resistance. Choose 6061 when you need high structural strength.

Have a Project Requiring 3003 Aluminum Plate?

While this guide provides general information, every project has unique requirements. At HXM Aluminum, we don’t just sell metal; we provide solutions. Our team can help you with:

Material Selection: Confirming if 3003 is the most cost-effective choice for your needs.

Precision Cutting: Supplying plates cut-to-size to minimize your waste and labor.

Quality Assurance: Providing full Mill Test Certificates (MTC) with every order.

If you’re ready to discuss your requirements or need a formal quote for your project, please contact our expert team.

FAQ

Is 3003 aluminum heat-treatable?

No, 3003 aluminum is non-heat-treatable. Strength is achieved through cold working.

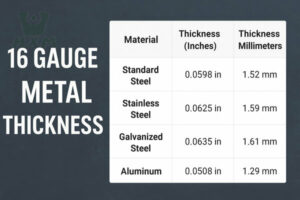

What thicknesses are available for 3003 aluminum plate?

We supply 3003 aluminum plates in thicknesses ranging from 0.5mm to 6mm, with custom sizes available upon request.

Is 3003 aluminum suitable for outdoor use?

Yes, it has excellent corrosion resistance, making it ideal for outdoor roofing, siding, and HVAC applications.

Can I get a sample before placing a bulk order?

Absolutely. Contact Huaxiao Metal, and we can provide samples for evaluation.

Huaxiao Metal is a leading aluminum sheet supplier in China, dedicated to providing high-quality aluminum alloy products and one-stop metal processing solutions to customers worldwide. We strictly adhere to ISO9001 standards to ensure that every batch of material you receive possesses superior performance and quality.

If you have any further technical questions or business cooperation inquiries, please feel free to contact us: Email: [email protected] Phone/WhatsApp/WeChat: +86-13761906384