Aluminium flat wire, also known as flat aluminum wire, is a versatile and durable material used in various industries including electronics, automotive, aerospace, and construction. Its excellent properties – lightweight, corrosion resistance, and superior conductivity – make it a top choice for producers across a wide range of industries.

At Huaxiao Metal, we are proud to be one of the leading suppliers and manufacturers of aluminum flat wire in China, offering quality products that meet international standards at competitive prices. With an extensive inventory and an experienced team, we aim to meet all of our customers’ project needs efficiently.

Aluminium Flat Wire Specification

Alloy material: 1050, 1070, 1350, 1370, 5056, etc.

Standard: GB5584.3-2009, IEC 60317-16 60317-16/28, MW36 60317-29 BS6811, MW18 60317-18, MW20 60317-47, etc.

Thickness: 0.05mm – 5.60mm

Width: 2.00mm – 18.00mm

Width/thickness ratio: 1.4<w/t<8.0

Type: Flat

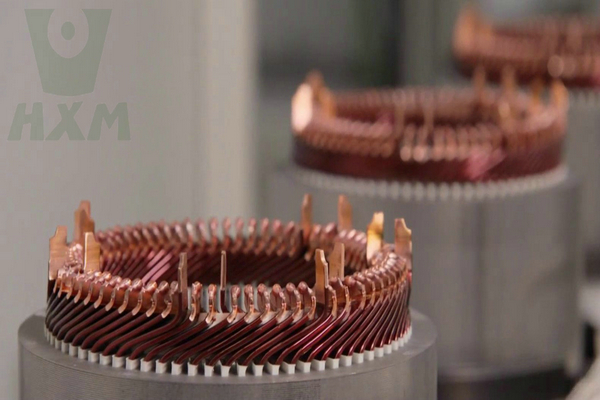

Aluminum flat wire is an aluminum wire with a flat cross section. It is usually made of aluminum alloy and has the characteristics of light weight, good conductivity and corrosion resistance. Aluminum flat wire is widely used in electrical equipment, electromagnetic coils, transformers and motors. Its flat shape makes it suitable for wiring in limited spaces, and it can also be used to make flat coils and coil conductors.

Application Of Aluminum Flat Wire

1. Electronics Industry

- Used in transformers, motors, and other electrical components for its excellent conductivity.

- Ideal for winding coils and creating compact yet efficient electrical circuits.

2. Automotive Sector

- Lightweight properties reduce overall vehicle weight, improving fuel efficiency.

- Widely used in wiring systems, battery connectors, and EV charging components.

3. Construction and Architecture

- Utilized in structural components, decorative finishes, and sealing systems.

- Provides corrosion resistance for long-lasting performance in outdoor environments.

4. Aerospace Industry

- Offers strength and lightweight properties critical for aerospace applications.

- Used in high-stress environments due to its durability and corrosion resistance.

5. General Manufacturing

- Applied in fasteners, decorative items, and custom industrial components.

- Suited for creative applications like art installations and custom designs.

- Lightweight and Durable: Perfect for applications where weight reduction is critical.

- Superior Conductivity: Ensures efficient performance in electrical systems.

- Corrosion Resistant: Long-lasting even in harsh environmental conditions.

- Easy to Customize: Available in a variety of shapes, sizes, and finishes.

- Eco-Friendly Material: Aluminum’s recyclability makes it a sustainable choice.

Are you searching for aluminium flat wire suppliers or flat aluminum wire manufacturers? Look no further! At HXM, we ensure high-quality products, competitive pricing, and excellent customer service.

FAQ

Most frequent questions and answers

Features of Aluminium Flat Wire

1. High-Grade Material Composition

Our aluminium flat wire is made from high-purity aluminum (up to 99.7%), ensuring outstanding performance in both electrical and mechanical applications. The material’s lightweight yet durable nature enhances its usability across various industries.

2. Advanced Manufacturing Process

Using state-of-the-art equipment and strict quality control, we ensure that every aluminum flat wire meets global standards such as ASTM, DIN, and ISO certifications. Our advanced annealing and surface treatment processes guarantee smooth finishes and enhanced strength.

3. Customization for Every Need

We understand that every project is unique. That’s why we offer custom sizes, widths, and thicknesses to meet specific requirements. Whether you need polished, anodized, or coated finishes, we can tailor the product to your exact specifications.

4. Eco-Friendly and Sustainable

Aluminum is 100% recyclable, making it an environmentally responsible choice for modern industries. Choosing our aluminium flat wire contributes to sustainability while meeting high-performance demands.

How to make Flat Aluminum Wire?

Melting and Casting

Aluminum ingots are melted and an appropriate amount of alloying elements are added to produce aluminum slabs through a continuous casting process.

Hot Rolling and Cold Rolling

Aluminum slabs are thinned by hot rolling to form aluminum strips of initial thickness, and then the thickness and width are precisely adjusted through a cold rolling process.

Flat Forming

Aluminum strips are processed into flat wires using special rolling equipment, with strict dimensional tolerances to ensure consistency.

Heat Treatment and Surface Treatment

Heat treatment (such as T4 and T6 states) is performed as required to improve mechanical properties; at the same time, the surface is polished and cleaned, and an anti-corrosion coating is added if necessary.

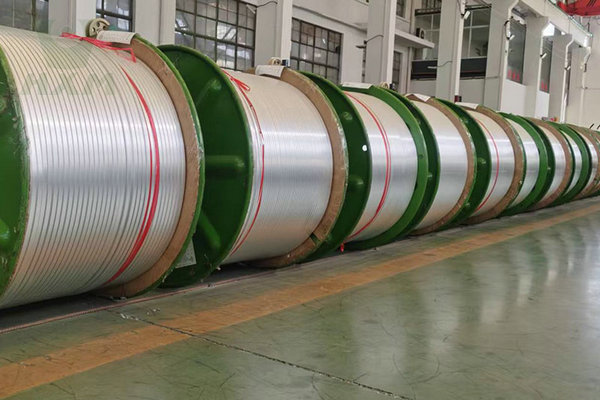

Cutting and Packaging

Cut to the required length according to specifications, and then leave the factory after moisture-proof packaging.

Flat aluminum wire for jewelry making

Flat aluminum wire is lightweight, corrosion-resistant, and easy to bend or shape, making it ideal for creating intricate jewelry designs. Its smooth surface and ability to hold finishes like anodizing or coloring enhance its aesthetic appeal.

Aluminum flat wire for crafts

Aluminum flat wire is lightweight, flexible, and easy to shape, making it perfect for various craft projects. It is also affordable, durable, and available in multiple colors and finishes.

Can samples be provided?

Yes, we can provide customers with small quantities of samples for testing. Please contact our sales team for details.