We are the place you need if you are looking for a high-quality 8011 aluminum sheet. As one of the professional 8011 aluminum sheet suppliers and manufacturers in China, the aluminum sheet we provide meets industry standards and has a very high-cost performance. Whether you are using it for food packaging or other applications, our 8011 aluminum sheet can meet your needs.

I hope you can find the information you need here, feel free to contact us for more details and the latest 8011 aluminum sheet price.

8011 Aluminum Sheets Specifications

Standards: ASTM, ASME, AMS, GB/T, JIS

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H112, etc.

Delivery Time: 7-20 days.

8011 Aluminum Sheet Data Sheet

Chemical Composition of 8011 Aluminum Plate Alloy

| Element | Typical Range |

|---|---|

| Al | Balance (98.7% – 99.7%) |

| Fe | 0.50% – 0.80% |

| Si | 0.30% – 0.60% |

| Cu | 0.05% – 0.20% |

| Mn | 0.05% – 0.35% |

| Mg | 0.05% – 0.20% |

| Zn | 0.10% – 0.25% |

| Other Elements | Typically less than 0.05% each |

Mechanical Properties of 8011 Aluminum Plate Alloy with Different Tempers

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| O (Annealed) | 60 – 90 | 35 – 55 | 20 – 30 | 30 – 40 |

| H12 | 80 – 110 | 60 – 80 | 10 – 20 | 40 – 50 |

| H14 | 90 – 130 | 80 – 100 | 8 – 15 | 50 – 60 |

| H16 | 100 – 140 | 100 – 120 | 5 – 10 | 60 – 70 |

| H18 | 110 – 150 | 120 – 140 | 3 – 8 | 70 – 80 |

8011 Aluminum Plate Physical Properties

| Property | Value |

|---|---|

| Density | 2.71 g/cm³ (2710 kg/m³) |

| Melting Point | ~660°C (1220°F) |

| Thermal Conductivity | ~237 W/m·K |

| Electrical Conductivity | ~37% IACS (International Annealed Copper Standard) |

| Specific Heat Capacity | ~0.897 J/g·K |

| Modulus of Elasticity | ~70 GPa (10,000 ksi) |

| Thermal Expansion Coefficient | ~23 x 10⁻⁶ /°C |

| Poisson’s Ratio | ~0.33 |

Different Tempers of 8011 Aluminum Sheet Metal

O (Annealed): This temper indicates that the aluminum sheet has been softened through an annealing process, which enhances its ductility and formability but results in lower strength.

H12: Represents a partially hardened state achieved through cold working, balancing strength and formability.

H14: Indicates a further hardened state, providing increased strength while sacrificing some of the ductility and formability compared to H12.

H16: More hardened than H14, suitable for applications where higher strength is required but with reduced elongation.

H18: The highest level of hardness in this series, delivering maximum strength but with minimal elongation and formability.

Applications of 8011 Aluminum Sheet Metal

Packaging:

- Food and Beverage Packaging: 8011 aluminum sheets are commonly used in food and beverage packaging, including foil containers, lids, and wrappers, due to their excellent barrier properties that protect contents from moisture, light, and contamination.

- Pharmaceutical Packaging: The alloy is also used for packaging medications and medical products because it provides a protective barrier against external elements and maintains the integrity of the contents.

Automotive Industry:

- Heat Shields: 8011 aluminum sheets are employed in automotive heat shields and exhaust systems to manage heat and protect other components from high temperatures.

- Interior Components: Used in certain interior automotive parts due to their lightweight and aesthetic qualities.

Electrical and Electronics:

- Electrical Insulation: The alloy is utilized in the manufacturing of electrical insulators and heat sinks due to its good thermal conductivity and electrical insulation properties.

Construction:

- Roofing and Siding: Although less common than other alloys, 8011 aluminum sheets can be used in some roofing and siding applications where lightweight and corrosion resistance are beneficial.

- Decorative Panels: Sometimes used for decorative and architectural panels where a high-quality finish is required.

Household Items:

- Kitchen Utensils and Appliances: The alloy is found in various kitchen items such as baking trays, foil, and other household goods due to its formability and resistance to high temperatures.

Industrial Applications:

- Heat Exchangers: Utilized in heat exchangers and other equipment where thermal management is critical, thanks to its good thermal conductivity.

Consumer Goods:

- Electronics Housings: Used in the casings and housings of consumer electronic devices due to their ability to be easily formed and finished.

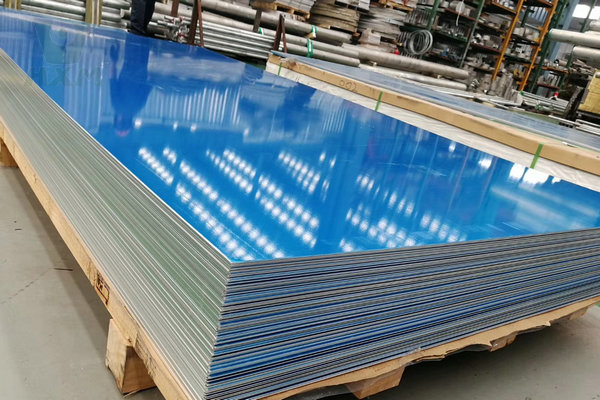

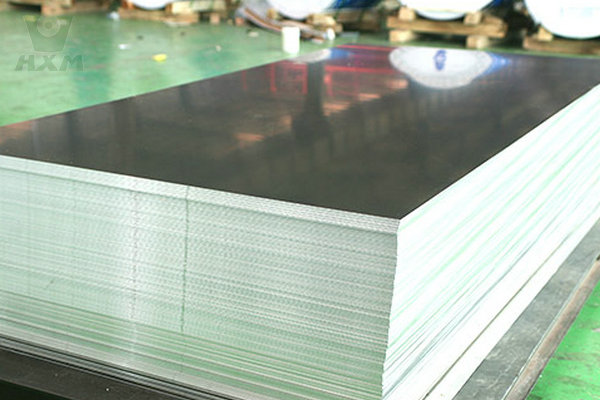

8011 Aluminum Sheet Packages

The following is our company’s conventional export packaging for aluminum plates. If you have special packaging requirements, our company can meet them. We very much hope to become one of your aluminum plate suppliers!