7050 aluminum wire is a premium aluminum alloy known for its outstanding strength, corrosion resistance, and toughness, making it a top choice for industries such as aerospace, automotive, and defense. This alloy combines high performance and reliability, providing a great role in industries where strength and durability are critical.

If you are looking for a trusted supplier of 7050 aluminum wire or would like to explore its unique benefits, we offer 7050 aluminum wire in a variety of diameters, tempers, and finishes and can customize this high-strength wire to meet your exact specifications. Whether you need it for aircraft parts, marine hardware, or industrial machinery, we have you covered. Contact us today for 7050 aluminum wire pricing!

Contact us today to get a custom quote, explore our inventory, or discuss your needs with our experts.

7050 Aluminum Wire Specifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: O, T6, T76, T651, T7451, T73651, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: AMS 4050, AMS 4201, DMS-2233, BMS 7-323, ASTM B221, EN3982, etc.

Delivery Time: 7-20 days.

7050 Aluminum Wire Data Sheet

Equivalent Grades Of Aluminum 7050 Wire

| Standard | 7050 Aluminum | Equivalent Grades | Notes |

|---|---|---|---|

| Aluminum Association (AA) | 7050 | – | Standard aluminum alloy designation |

| International Organization for Standardization (ISO) | 7050 | 3.4164 | Comparable performance to 7050 |

| Deutsches Institut für Normung (DIN) | – | EN AW-7050 | Standard corresponding designation |

| British Standards (BS) | – | 7075-T6 | 7075-T6 is often used interchangeably with 7050 in UK standards |

| Japanese Industrial Standards (JIS) | – | A7075-T6 | A7075-T6 is similar to 7050 under JIS standards |

| Chinese National Standards (GB) | – | 7075-T6 | 7075-T6 is commonly used as an equivalent in China |

Chemical Composition of 7050 Aluminum Wire

Below is a typical chemical composition for 7050 aluminum wire:

| Element | Chemical Composition (%) |

|---|---|

| Al | Balance (approximately 90.7 – 94.7%) |

| Zn | 5.7 – 6.7% |

| Cu | 2.0 – 2.6% |

| Mg | 2.2 – 2.8% |

| Mn | 0.1 – 0.3% |

| Cr | 0.04 – 0.35% |

| Si | 0.1% max |

| Fe | 0.2% max |

| Ti | 0.05 – 0.15% |

| Other Elements | Each 0.05% max, Total 0.15% max |

Mechanical Properties and Tempers of 7050 Aluminium Wire

| Property | 7050-T6 | 7050-T7451 | 7050-T651 | 7050-T76 |

|---|---|---|---|---|

| Yield Strength (MPa) | 503 – 572 | 483 – 540 | 483 – 552 | 483 – 552 |

| Ultimate Tensile Strength (MPa) | 572 – 641 | 552 – 620 | 552 – 621 | 552 – 621 |

| Elongation (%) | 8 – 10 | 10 – 12 | 10 – 12 | 10 – 12 |

| Shear Strength (MPa) | 431 – 517 | 414 – 482 | 414 – 482 | 414 – 482 |

| Hardness (Brinell) | 150 – 180 | 145 – 175 | 145 – 175 | 145 – 175 |

For high-quality 7050 aluminum wire and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7050 Aluminum Wires Metal

7050 aluminum alloy is a high-strength aluminum alloy widely used in aerospace and other applications requiring high strength and corrosion resistance. 7050 aluminum wire can have a variety of different states according to its heat treatment process, and each state has its specific performance and applicable scenarios. The following are several common states (Tempers) of 7050 aluminum wire and their characteristics:

7050-T6

Features: the 7050-T6 state is the most commonly used heat treatment state in 7050 aluminum alloy. After T6 treatment, the 7050 aluminum wire has excellent strength, hardness, and corrosion resistance after dissolution treatment and artificial aging.

Application: Mainly used in structural parts, aircraft wings, and fuselage parts in the aerospace field.

7050-T7451

Features: The 7050-T7451 state has a higher resistance to stress corrosion cracking than the T6 state. Through a special heat treatment process and stabilization treatment, the T7451 state provides better comprehensive performance, especially tolerance to the environment.

Application: Suitable for applications with higher requirements for stress corrosion cracking resistance, such as aircraft structural parts and high-load components.

7050-T651

Features: The 7050-T651 state is a modified version of the T6 state with higher processability. By performing tensile stress release treatment after heat treatment, the internal stress is reduced, thereby improving the mechanical properties and processing performance.

Application: Widely used in aluminum alloy parts with complex structures, such as aircraft fuselage structural parts.

7050-T76

Features: The 7050-T76 state is an aged state that provides good mechanical properties and higher stress corrosion resistance. It is mainly solution treated and naturally aged to provide balanced performance characteristics.

Application: Suitable for structural parts and aviation components that require higher corrosion resistance and stability.

Applications of 7050 Aluminum Wire Metal

Aerospace

Used in fuselage frames, bulkheads, and wing structures due to its high strength and lightweight.

Automotive

Ideal for high-performance parts in racing and lightweight vehicle components.

Defense and Military

Used in armored vehicles, missile components, and other military-grade applications.

Marine

Suitable for shipbuilding and marine components requiring high corrosion and wear resistance.

High-Performance Equipment

Commonly used in robotics, industrial machinery, and precision tools where reliability is critical.

Are you looking for wire that can withstand extreme stress and heavy loads? With its high strength and excellent fatigue resistance, 7050 aluminum wire is ideal for aerospace, defense, and industrial applications. Whether you’re manufacturing aircraft parts or heavy machinery, 7050 aluminum wire provides the durability you need. Contact us today for a 7050 aluminum wire quote and learn how 7050 aluminum wire can enhance your project!

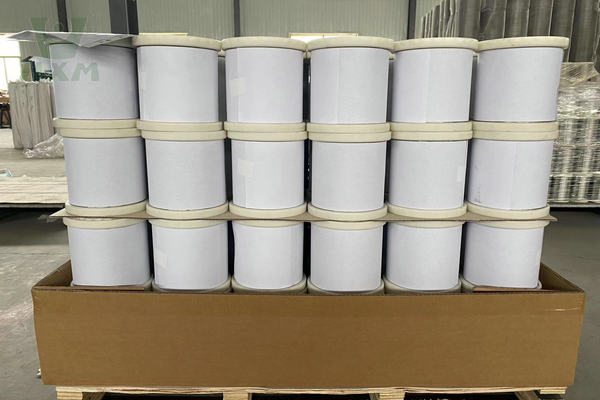

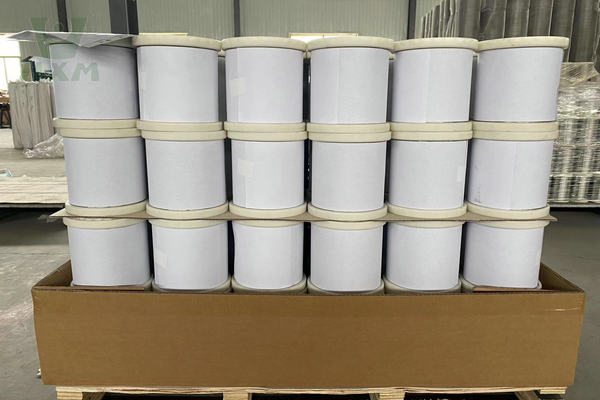

7050 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 7050 Aluminum Wire?

7050 Aluminum Wire is part of the 7000 aluminum alloy series, primarily alloyed with zinc and magnesium, along with trace elements of copper and chromium. Designed to offer high strength and superior stress corrosion cracking resistance, 7050 is frequently used in applications that require structural integrity in extreme environments.

Features of 7050 Aluminum Wire

Exceptional Strength

Delivers superior strength comparable to some steels, ensuring reliable performance.

Excellent Corrosion Resistance

Specially treated to resist stress corrosion cracking and exfoliation, making it ideal for harsh environments.

Lightweight Design

Provides high strength without adding unnecessary weight, perfect for the aerospace and automotive industries.

Toughness and Fatigue Resistance

Performs exceptionally well in dynamic loading conditions and environments subject to wear and tear.

Customizable Tempers

Available in a variety of tempers like T6, T7451, and T76 to meet diverse engineering requirements.

Advantages of 7050 Aluminum Wire

Unmatched Strength and Weight Ratio

Ideal for applications where weight reduction without compromising strength is essential.

Corrosion Resistance

Proven performance in marine, aerospace, and industrial environments.

Customizable Solutions

Multiple tempers allow tailoring the alloy to meet specific project needs.

Sustainability

Fully recyclable, contributing to environmental conservation initiatives.

Can 7050 Aluminum Wire be welded?

Welding 7050 Aluminum Wire is challenging due to its high zinc content, but advanced techniques like friction stir welding can achieve successful results.

What are the common tempers for 7050 Aluminum Wire?

Popular tempers include T7451 for enhanced corrosion resistance and T6 for optimal strength.

Why Choose Us As Your 7050 Aluminum Wire Supplier?

HXM is a trusted supplier of high-quality 7050 Aluminum Wire, offering:

Custom Sizes and Tempers to meet your specific requirements.

Competitive Pricing for bulk and project orders.

Global Delivery with quick turnaround times.

Contact us now to get a customized quote, learn about our inventory, or discuss your needs with our experts.

Invest in the strength, versatility, and reliability of 7050 Aluminum Wire for your next project!

Arabic

Arabic Bulgarian

Bulgarian Dutch

Dutch English

English French

French German

German Indonesian

Indonesian Italian

Italian Japanese

Japanese Korean

Korean Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovenian

Slovenian Spanish

Spanish Thai

Thai