HXM is one of the trusted 7075 aluminum coil suppliers and manufacturers in China, we provide coils that excel in demanding applications, including aerospace, defense, and high-stress structural components. Our 7075 aluminum coils are renowned for their exceptional tensile strength, fatigue resistance, and durability.

Whether you’re looking for coils for aircraft structures or other high-performance uses, our 7075 aluminum coil stock ensures that you have access to the materials you need when you need them.

Contact us today to learn more about our 7075 aluminum coil offerings and request a quote tailored to your specific requirements.

7075 Aluminium Coil Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.2~300mm

Width: 500~2500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

7075 Aluminum Coil Data Sheet

Equivalent Grades Of Aluminum 7075 Coil

| Standard | 7075 Aluminum | Equivalent Grades | Notes |

|---|---|---|---|

| Aluminum Association (AA) | 7075 | – | Standard aluminum alloy designation |

| International Organization for Standardization (ISO) | 7075 | 3.4365 | Comparable performance to 7075 |

| Deutsches Institut für Normung (DIN) | – | EN AW-7075 | Standard corresponding designation |

| British Standards (BS) | – | 7075-T6 | 7075-T6 is commonly used interchangeably |

| Japanese Industrial Standards (JIS) | – | A7075-T6 | A7075-T6 is similar under JIS standards |

| Chinese National Standards (GB) | – | 7075-T6 | 7075-T6 is often used as an equivalent |

Chemical Composition of 7075 Aluminum Coil

| Element | Chemical Composition (%) |

|---|---|

| Al | Balance (approximately 87.1 – 91.4%) |

| Zn | 5.1 – 6.1% |

| Cu | 1.2 – 2.0% |

| Mg | 2.1 – 2.9% |

| Mn | 0.3% max |

| Cr | 0.18 – 0.28% |

| Si | 0.4% max |

| Fe | 0.5% max |

| Ti | 0.2% max |

| Other Elements | Each 0.05% max, Total 0.15% max |

Mechanical Properties and Tempers of 7075 Aluminium Coil

| Property | 7075-T6 | 7075-T651 | 7075-T7 | 7075-T76 |

|---|---|---|---|---|

| Yield Strength (MPa) | 503 – 572 | 483 – 552 | 414 – 482 | 483 – 552 |

| Ultimate Tensile Strength (MPa) | 572 – 641 | 552 – 621 | 483 – 552 | 552 – 621 |

| Elongation (%) | 8 – 10 | 10 – 12 | 8 – 10 | 10 – 12 |

| Shear Strength (MPa) | 414 – 517 | 414 – 482 | 414 – 482 | 414 – 482 |

| Hardness (Brinell) | 150 – 180 | 145 – 175 | 150 – 180 | 145 – 175 |

For high-quality 7075 aluminum coil and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7075 Aluminum Coils Metal

7075 aluminum coil metal is renowned for its high strength and versatility, making it suitable for various demanding applications. The properties of 7075 aluminum can vary significantly depending on its temper, which refers to the heat treatment and aging process it undergoes. Here’s a breakdown of the most common tempers for 7075 aluminum coil metal:

7075-T6

- Properties: This is one of the most widely used tempers for 7075 aluminum. It offers the highest strength and is known for its excellent mechanical properties. It has good resistance to stress corrosion cracking and is often used in aerospace and structural applications.

- Applications: Aircraft structures, marine components, and high-stress components.

7075-T651

- Properties: Similar to T6 but with a slightly different processing method that reduces internal stresses. It has the same high strength as T6 but with improved machinability.

- Applications: Aerospace components, high-strength structural parts, and tooling.

7075-T73

- Properties: This temper is an alternative to T6, with similar strength but enhanced stress corrosion resistance and improved toughness. It undergoes a solution heat treatment followed by aging at a lower temperature.

- Applications: Aerospace parts requiring good corrosion resistance and strength, such as fuselage frames and wing skins.

7075-T76

- Properties: This is an alternative to T73 with similar mechanical properties but offers improved resistance to localized corrosion.

- Applications: Specialized aerospace components and high-performance marine applications.

7075-O

- Properties: The ‘O’ temper denotes that the aluminum is in its soft, annealed state. This temper is not as strong as T6 but provides the maximum ductility and is easier to form and machine.

- Applications: Pre-machining or forming, and applications requiring extensive shaping.

7075-T3 and 7075-T4

- Properties: These are less commonly used but are still relevant. T3 is solution heat-treated and cold worked, offering good strength and formability. T4 is similar but requires additional aging for increased strength.

- Applications: Aerospace and military applications, where high strength and corrosion resistance are necessary.

Applications of 7075 Aluminum Coil Metal

Aerospace: Commonly used in aircraft structures, including wing and fuselage components, where high strength and lightweight properties are crucial.

Military: Utilized in military equipment and vehicles due to its strength and durability.

Automotive: Employed in high-performance racing and automotive applications where weight and strength are critical.

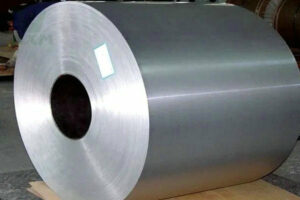

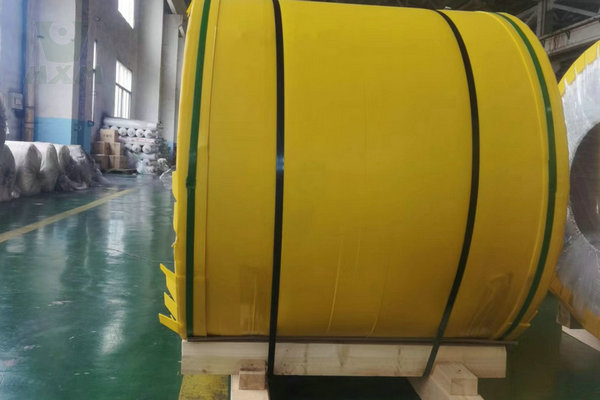

7075 Aluminum Coil Packages

The following is our company’s standard aluminum coil export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 7075 Aluminum Coil?

7075 aluminum coil is a high-strength alloy that excels in applications requiring superior strength, durability, and resistance to fatigue. It is widely used in aerospace, military, and high-performance automotive industries, making it a top choice for demanding applications.

7000 Series Aluminum

7075 Aluminum Coil VS Other Aluminum Coil:

| Property | 7075 Aluminum Coil | 2024 Aluminum Coil | 7050 Aluminum Coil | 6061 Aluminum Coil | 5052 Aluminum Coil |

|---|---|---|---|---|---|

| Tensile Strength | 505 – 570 MPa (73 – 83 ksi) | 420 – 500 MPa (61 – 73 ksi) | 505 – 570 MPa (73 – 83 ksi) | 240 – 310 MPa (35 – 45 ksi) | 210 – 260 MPa (30 – 38 ksi) |

| Yield Strength | 435 – 505 MPa (63 – 73 ksi) | 345 – 415 MPa (50 – 60 ksi) | 435 – 505 MPa (63 – 73 ksi) | 155 – 270 MPa (22 – 39 ksi) | 105 – 135 MPa (15 – 20 ksi) |

| Corrosion Resistance | Good (Stress corrosion resistant) | Fair (Prone to stress corrosion cracking) | Good (Stress corrosion resistant) | Good (General use) | Excellent (Marine environments) |

| Fatigue Resistance | Excellent | Good | Excellent | Good | Good |

| Heat Treatability | High | High | High | High | Limited |

| Workability | Moderate | Moderate | Moderate | Excellent | Good |

| Weldability | Moderate | Fair | Moderate | Excellent | Good |

| Applications | Aerospace, military, high-stress automotive | Aerospace, structural components | Aerospace, military, high-stress automotive | Aerospace, structural, automotive | Marine, automotive, tanks |

- 7075 Aluminum Coil: Known for its high strength and excellent fatigue resistance, making it suitable for aerospace, military, and high-stress automotive applications. It is heat-treatable and has good stress corrosion resistance but is less formable and weldable compared to some other alloys.

2024 Aluminum Coil: Provides high strength and is commonly used in aerospace applications. It has good fatigue resistance but is more prone to stress corrosion cracking compared to 7075.

7050 Aluminum Coil: Similar to 7075 in strength and stress corrosion resistance, this alloy is used in aerospace and military applications where high strength and durability are crucial.

6061 Aluminum Coil: Offers a good balance of strength, workability, and corrosion resistance, making it suitable for a wide range of applications, including structural and automotive. It is highly weldable and versatile.

5052 Aluminum Coil: Known for its excellent corrosion resistance, particularly in marine environments. It has lower strength compared to 7075 and is suitable for applications requiring high corrosion resistance and moderate strength.

How Can I Get A Sample Of 7075 Aluminum Coils?

Please contact us directly and send us the material, specification, quantity, and delivery address of the samples you need.

Features of 7075 Aluminum Coil:

Alloy Series: 7000 Series

High Strength: 7075 aluminum is one of the strongest aluminum alloys available, offering high tensile and yield strength, which makes it ideal for structural applications requiring maximum strength.

Heat Treatability: This alloy can be heat-treated to achieve its peak strength, making it suitable for aerospace and other high-stress environments.

Fatigue Resistance: The alloy has excellent fatigue resistance, making it ideal for components subject to cyclic loading and high-stress conditions.

Stress Corrosion Resistance: While it has good resistance to stress corrosion cracking, it is typically less resistant than some other aluminum alloys such as 5052 or 6061.