China 7005 Aluminum Coils Suppliers & Manufacturers

HXM is a leading 7005 aluminum coil supplier and manufacturer in China. We provide aluminum coils with excellent strength and durability, which are ideal for aerospace, sports equipment, and structural applications. Our 7005 aluminum coils are carefully designed to have excellent fatigue resistance and a high strength-to-weight ratio.

Are you looking for 7005 aluminum coil prices? We have a lot of 7005 aluminum coils in stock in our warehouse, and I believe we can give you a competitive price and fast delivery.

Contact us today to learn more about our 7005 aluminum coil products and get a custom quote.

7005 Aluminium Coil Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.2~300mm

Width: 500~2500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

7005 Aluminum Coil Data Sheet

Equivalent Grades Of Aluminum 7005 Coil

| Standard | Equivalent Grade | Description |

|---|---|---|

| International Standards | ||

| DIN | DIN 3.4365 | Similar properties but not a direct match |

| BS | BS L109 | Close equivalent in terms of properties |

| AFNOR | AFNOR 7020 T6 | 7020 alloy, though different, shares some characteristics with 7005 |

| U.S. Military Standards | ||

| MIL-DTL-5005 | MIL-DTL-5005 | Includes several alloys similar to 7005, used in military and aerospace applications |

| Chinese Standards | ||

| GB/T 3190-2008 | GB/T 3190-2008 | Includes equivalent grades for 7000 series alloys; specific equivalents may vary |

| Japanese Standards | ||

| JIS | JIS A7075 | Not a direct equivalent but similar in strength and applications |

| International Standards | ||

| ISO | ISO 209 | General specification for aluminum and its alloys; specific equivalents may be found based on alloy composition and mechanical properties |

Chemical Composition of 7005 Aluminum Coil

| Element | Typical Range (%) |

|---|---|

| Al | 90.7 – 94.7 |

| Zn | 4.2 – 4.7 |

| Mg | 1.2 – 1.8 |

| Cu | 0.7 – 1.0 |

| Mn | 0.3 – 0.6 |

| Cr | 0.18 – 0.28 |

| Si | 0.10 – 0.25 |

| Fe | 0.15 – 0.40 |

| Ti | 0.05 – 0.15 |

| Other Elements | Each ≤ 0.05 |

Mechanical Properties and Tempers of 7005 Aluminium Coil

| Temper | Ultimate Tensile Strength (UTS) | Yield Strength (YS) | Elongation | Hardness (HB) | Description |

|---|---|---|---|---|---|

| T6 | ~310 – 450 MPa (45 – 65 ksi) | ~250 – 380 MPa (36 – 55 ksi) | 8% – 12% | 85 – 95 HB | High strength and fatigue resistance, heat-treated for maximum hardness. |

| T651 | ~310 – 450 MPa (45 – 65 ksi) | ~250 – 380 MPa (36 – 55 ksi) | 8% – 12% | 85 – 95 HB | Similar to T6 but relieved by stretching for improved dimensional stability. |

| T73 | ~310 – 450 MPa (45 – 65 ksi) | ~250 – 380 MPa (36 – 55 ksi) | 8% – 12% | 85 – 95 HB | Good strength with enhanced resistance to stress-corrosion cracking, aged to stable condition. |

| T74 | ~310 – 450 MPa (45 – 65 ksi) | ~250 – 380 MPa (36 – 55 ksi) | 8% – 12% | 85 – 95 HB | Aged to a specific strength level for precise performance requirements. |

| O | ~150 – 250 MPa (22 – 36 ksi) | ~80 – 150 MPa (11 – 22 ksi) | 15% – 20% | 60 – 80 HB | Fully annealed with lower strength, offering enhanced formability and ductility. |

7005 aluminum coil is a high-strength aluminum alloy material, mainly composed of aluminum, zinc, and magnesium, with excellent mechanical properties and fatigue resistance. Its typical characteristics include high yield strength, good corrosion resistance, and excellent welding performance, suitable for applications in high-stress environments. Our 7005 aluminum coil meets international standards and provides a variety of thickness, width, and coil diameter options, and can provide customized surface treatments such as coating or polishing to meet the needs of different customers.

For high-quality 7005 aluminum sheets and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7005 Aluminum Coils Metal

Here is a table summarizing the different tempers of 7005 aluminum coils:

| Temper | Description | Properties | Applications |

|---|---|---|---|

| O | Fully annealed, softest state | High ductility, low strength | Applications requiring maximum formability |

| H12 | Slightly strain-hardened | Moderate strength, good formability | General-purpose applications needing a balance of strength and formability |

| H14 | Half-hard temper | Higher strength than H12, moderate formability | Applications requiring higher strength with some formability |

| H16 | Three-quarter hard temper | Higher strength than H14, lower formability | Structural applications needing higher strength |

| H18 | Fully strain-hardened | Maximum strength, minimal ductility | Applications requiring maximum strength and hardness |

| H32 | Strain-hardened and stabilized | Moderate strength, good formability, improved stability | Similar to H12 but with better dimensional stability |

| H34 | Strain-hardened and stabilized | Higher strength than H32, moderate formability, improved stability | Similar to H14 but with better dimensional stability |

| H36 | Strain-hardened and stabilized | Higher strength than H34, lower formability, improved stability | Similar to H16 but with better dimensional stability |

| H38 | Fully strain-hardened and stabilized | Maximum strength, minimal ductility, improved stability | Similar to H18 but with better dimensional stability |

| T6 | Solution heat-treated and artificially aged | High strength, good corrosion resistance | High-stress applications requiring maximum strength |

| T651 | Solution heat-treated, stress-relieved, and artificially aged | High strength, improved dimensional stability | Precision applications requiring dimensional stability |

| T73 | Solution heat-treated and overaged | Good strength, excellent stress corrosion resistance | Applications where stress corrosion resistance is critical |

| T7351 | Solution heat-treated, stress-relieved, and overaged | Good strength, excellent stress corrosion resistance, improved dimensional stability | Precision applications requiring stress corrosion resistance |

| T76 | Solution heat-treated and overaged | Good strength, excellent exfoliation corrosion resistance | Applications where exfoliation corrosion resistance is critical |

| T7651 | Solution heat-treated, stress-relieved, and overaged | Good strength, excellent exfoliation corrosion resistance, improved dimensional stability | Precision applications requiring exfoliation corrosion resistance |

Each temper of 7005 aluminum coils offers a unique combination of strength, ductility, and corrosion resistance, making them suitable for various industrial applications. The choice of temper depends on the specific requirements of the application, such as the need for formability, strength, or corrosion resistance.

Applications of 7005 Aluminum Coil Metal

Aerospace: Commonly used in aerospace components where strength and lightweight properties are crucial.

Sports Equipment: Employed in high-performance sports equipment such as bicycle frames and golf clubs due to its strength-to-weight ratio.

Structural Components: Used in various structural applications where high strength is required.

7005 aluminum coil is widely used in many fields due to its excellent strength and lightweight characteristics. In the aerospace industry, it is often used to manufacture aircraft structures and parts; in the transportation field, it is an ideal choice for manufacturing truck bodies and rail transit carriages; in mechanical manufacturing, 7005 aluminum coil is used to produce high-strength mechanical parts and molds; and in the field of sports equipment, its lightness and durability make it the preferred material for bicycle frames and mountaineering equipment.

No matter which industry your project belongs to, our 7005 aluminum coil can provide you with reliable solutions to help your project succeed.

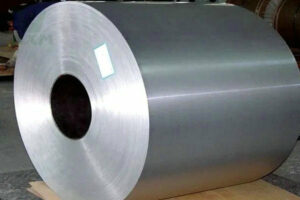

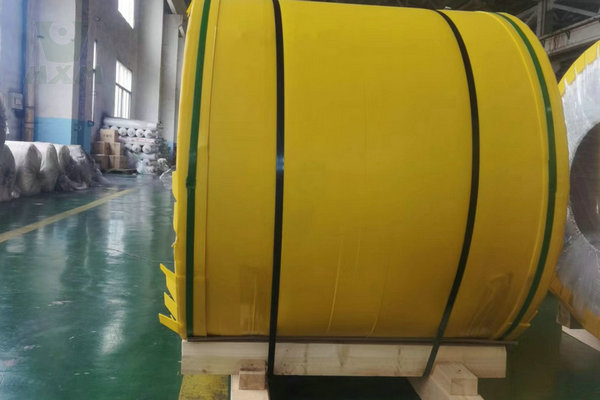

7005 Aluminum Coil Packages

The following is our company’s standard aluminum coil export packaging. If the customer has any packaging requirements, our company can meet them.

If you are looking for high-quality 7005 aluminum coil suppliers, please contact us now! Our sales team will provide you with detailed product information, competitive prices and fast delivery services. Click the button below to get a free quote.

FAQ

What Is 7005 Aluminum Coil?

7005 Aluminum Coil is part of the 7000 series of aluminum alloys, which are primarily alloyed with zinc.

7000 Series Aluminum

7005 Aluminum Coil VS Other Aluminum Coil:

| Property | 7005 Aluminum Coil | 6061 Aluminum Coil | 7075 Aluminum Coil | 2024 Aluminum Coil | 5052 Aluminum Coil |

|---|---|---|---|---|---|

| Tensile Strength | 345 – 430 MPa (50 – 62 ksi) | 240 – 310 MPa (35 – 45 ksi) | 505 – 570 MPa (73 – 83 ksi) | 420 – 500 MPa (61 – 73 ksi) | 210 – 260 MPa (30 – 38 ksi) |

| Yield Strength | 275 – 345 MPa (40 – 50 ksi) | 155 – 270 MPa (22 – 39 ksi) | 435 – 505 MPa (63 – 73 ksi) | 345 – 415 MPa (50 – 60 ksi) | 105 – 135 MPa (15 – 20 ksi) |

| Corrosion Resistance | Good (General use) | Good (General use) | Good (Stress corrosion resistant) | Fair (Prone to stress corrosion cracking) | Excellent (Marine environments) |

| Fatigue Resistance | Good | Good | Excellent | Good | Good |

| Heat Treatability | High | High | High | High | Limited |

| Workability | Moderate | Excellent | Moderate | Moderate | Good |

| Weldability | Moderate | Excellent | Moderate | Fair | Good |

| Applications | Aerospace, sports equipment, structural components | Aerospace, structural, automotive | Aerospace, military, high-stress automotive | Aerospace, structural components | Marine, automotive, tanks |

- 7005 Aluminum Coil: Known for its high strength and good fatigue resistance, making it suitable for aerospace, sports equipment, and structural applications. It has moderate workability and weldability and is heat-treatable to enhance its properties.

6061 Aluminum Coil: Offers a good balance of strength, workability, and corrosion resistance, making it versatile for a wide range of applications including aerospace, automotive, and structural components. Highly weldable and easy to work with.

7075 Aluminum Coil: Provides superior strength and fatigue resistance, ideal for high-performance applications such as aerospace and military. It is heat-treatable and has good stress corrosion resistance, but less formable and weldable than some other alloys.

2024 Aluminum Coil: Offers high strength and good fatigue resistance, commonly used in aerospace. However, it is more prone to stress corrosion cracking compared to 7005 and 7075.

5052 Aluminum Coil: Known for its excellent corrosion resistance, especially in marine environments, but has lower strength compared to 7005 and 7075. It is suitable for applications requiring high corrosion resistance and moderate strength.

How Can I Get A Sample Of 7005 Aluminum Coils?

Please contact us directly and send us the material, specification, quantity, and delivery address of the samples you need.

Features of 7005 Aluminum Coil:

Alloy Series: 7000 Series

High Strength: 7005 aluminum is renowned for its excellent tensile and yield strength, making it ideal for applications where high strength is essential.

Heat Treatability: This alloy can be heat-treated to enhance its mechanical properties, which is valuable for high-performance applications.

Fatigue Resistance: It offers good fatigue resistance, which is crucial for components subjected to cyclic loading and stress.

Corrosion Resistance: While it has good general corrosion resistance, it is not as resistant to stress corrosion cracking as some other alloys like 5052 or 6061.

As a professional 7005 aluminum coil supplier and manufacturer in China, we focus on providing customers with high-strength and lightweight aluminum solutions. 7005 aluminum coil has become an ideal choice for industries such as aerospace, transportation, and machinery manufacturing due to its excellent strength, corrosion resistance, and welding performance. Whether you need standard specifications or customized requirements, our team can provide you with high-quality products and efficient services to ensure the smooth completion of your project.