Are you looking for 7050 aluminum sheet manufacturers? As a leading 7050 aluminum plate supplier and manufacturer, we focus on providing high-quality aluminum alloy plates to meet various industrial needs. 7050 aluminum plate is widely used in aerospace and military fields due to its excellent strength and corrosion resistance. Our products will be your best choice if you are looking for top 7050 aluminum plate suppliers.

Whether it is 7050 aluminum plate price, specifications, or customized needs, we can provide solutions to meet your requirements. Please browse our product information for the most competitive 7050 aluminum plate prices and services.

7050 Aluminium Sheets Specifications

Standards: AMS 4050; AMS STD 2154; ASTM B594; BAMS 516-003; ASTM B209 / ASME SB209, etc.

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: O, T6, T76, T7651, T7451, etc.

Delivery Time: 7-20 days.

7050 Aluminum Sheet Data Sheet

Equivalent Grades Of Aluminum 7050 Plate

| Standard | 7050 Aluminum | Equivalent Grades | Notes |

|---|---|---|---|

| Aluminum Association (AA) | 7050 | – | Standard aluminum alloy designation |

| International Organization for Standardization (ISO) | 7050 | 3.4164 | Comparable performance to 7050 |

| Deutsches Institut für Normung (DIN) | – | EN AW-7050 | Standard corresponding designation |

| British Standards (BS) | – | 7075-T6 | 7075-T6 is often used interchangeably with 7050 in UK standards |

| Japanese Industrial Standards (JIS) | – | A7075-T6 | A7075-T6 is similar to 7050 under JIS standards |

| Chinese National Standards (GB) | – | 7075-T6 | 7075-T6 is commonly used as an equivalent in China |

Chemical Composition of 7050 Aluminum Sheet

Below is a typical chemical composition for 7050 aluminum sheets & plates:

| Element | Chemical Composition (%) |

|---|---|

| Al | Balance (approximately 90.7 – 94.7%) |

| Zn | 5.7 – 6.7% |

| Cu | 2.0 – 2.6% |

| Mg | 2.2 – 2.8% |

| Mn | 0.1 – 0.3% |

| Cr | 0.04 – 0.35% |

| Si | 0.1% max |

| Fe | 0.2% max |

| Ti | 0.05 – 0.15% |

| Other Elements | Each 0.05% max, Total 0.15% max |

Mechanical Properties and Tempers of 7050 Aluminium Sheet

| Property | 7050-T6 | 7050-T7451 | 7050-T651 | 7050-T76 |

|---|---|---|---|---|

| Yield Strength (MPa) | 503 – 572 | 483 – 540 | 483 – 552 | 483 – 552 |

| Ultimate Tensile Strength (MPa) | 572 – 641 | 552 – 620 | 552 – 621 | 552 – 621 |

| Elongation (%) | 8 – 10 | 10 – 12 | 10 – 12 | 10 – 12 |

| Shear Strength (MPa) | 431 – 517 | 414 – 482 | 414 – 482 | 414 – 482 |

| Hardness (Brinell) | 150 – 180 | 145 – 175 | 145 – 175 | 145 – 175 |

For high-quality 7050 aluminum sheets and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 7050 Aluminum Sheet Metal

7050 aluminum alloy is a high-strength aluminum alloy widely used in aerospace and other applications requiring high strength and corrosion resistance. 7050 aluminum plate can have a variety of different states according to its heat treatment process, and each state has its specific performance and applicable scenarios. The following are several common states (Tempers) of 7050 aluminum plate and their characteristics:

7050-T6

Features: the 7050-T6 state is the most commonly used heat treatment state in 7050 aluminum alloy. After T6 treatment, the 7050 aluminum plate has excellent strength, hardness, and corrosion resistance after dissolution treatment and artificial aging.

Application: Mainly used in structural parts, aircraft wings, and fuselage parts in the aerospace field.

7050-T7451

Features: The 7050-T7451 state has a higher resistance to stress corrosion cracking than the T6 state. Through a special heat treatment process and stabilization treatment, the T7451 state provides better comprehensive performance, especially tolerance to the environment.

Application: Suitable for applications with higher requirements for stress corrosion cracking resistance, such as aircraft structural parts and high-load components.

7050-T651

Features: The 7050-T651 state is a modified version of the T6 state with higher processability. By performing tensile stress release treatment after heat treatment, the internal stress is reduced, thereby improving the mechanical properties and processing performance.

Application: Widely used in aluminum alloy parts with complex structures, such as aircraft fuselage structural parts.

7050-T76

Features: The 7050-T76 state is an aged state that provides good mechanical properties and higher stress corrosion resistance. It is mainly solution treated and naturally aged to provide balanced performance characteristics.

Application: Suitable for structural parts and aviation components that require higher corrosion resistance and stability.

Applications of 7050 Aluminum Sheet Metal

- Aerospace

- Military and defense

- Marine industry

- Automotive industry

- Sports equipment

- Industrial applications

- Tools and machinery

- High-load applications

7050 aluminum sheet is widely used in aerospace, automotive, and structural applications due to its excellent strength-to-weight ratio, high corrosion resistance, and exceptional machinability. This aluminum alloy is particularly valued in environments that require superior performance under high stress and fatigue conditions.

Leading 7050 aluminum plate suppliers offer this material in a variety of sizes and thicknesses, ensuring it meets the needs of industries such as aircraft manufacturing, military equipment, and high-performance automobiles. Contact a reliable 7050 aluminum plate supplier to learn more about pricing, availability, and customization options for your project.

Benefits of 7050 Aluminum Sheet Alloy:

-

High Strength: Provides superior strength compared to many other aluminum alloys, making it suitable for heavy-duty applications.

-

Fatigue Resistance: Excellent fatigue resistance, which is crucial for parts subject to cyclic loads.

-

Stress Corrosion Cracking Resistance: Good resistance to stress corrosion cracking, enhancing durability in challenging environments.

-

Lightweight: Offers a high strength-to-weight ratio, which is beneficial for applications where weight is a critical factor.

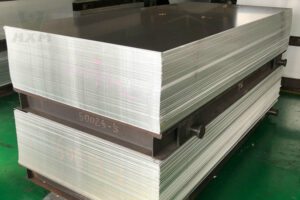

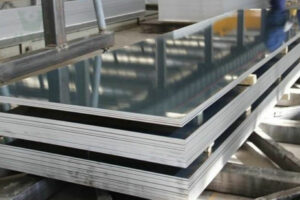

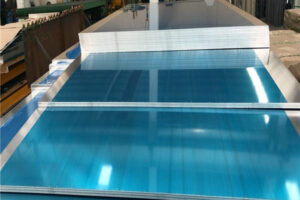

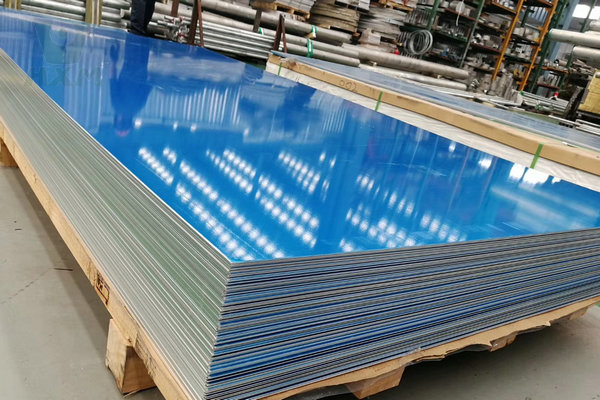

7050 Aluminum Sheet Packages

The following is our company’s conventional export packaging for aluminum plates. If you have special packaging requirements, our company can meet them. We very much hope to become one of your aluminum plate suppliers!

FAQ

What Is 7050 Aluminum Sheet?

7050 aluminum plate is a high-strength, heat-treatable aluminum alloy that is often used in aerospace and other demanding applications. Known for its excellent mechanical properties, especially its strength and resistance to stress corrosion cracking, 7050 aluminum is often used in applications that require high performance.

Comparison of 7050 Aluminum Sheet with Other Aluminum Sheets

Strength:

-

- 7050 and 7075 offer high tensile and yield strengths, making them suitable for high-stress applications. 7050 is particularly known for its stress-corrosion resistance, while 7075 is renowned for its overall strength.

- 2024 has slightly lower strength than 7050 and 7075 but still offers high strength and is often used in aerospace applications.

- 6061 is lower in strength compared to the other three alloys but provides good strength for structural components and is easier to work with.

Corrosion Resistance:

-

- 6061 has the best corrosion resistance among the alloys listed, making it ideal for marine and other corrosive environments.

- 7050 and 7075 have good corrosion resistance but can be prone to stress-corrosion cracking in certain conditions.

- 2024 has moderate corrosion resistance, often requiring protective coatings.

Machinability:

-

- 6061 is known for its excellent machinability, making it easier to work with compared to the other alloys.

- 7050 and 7075 are more challenging to machine, especially in heat-treated conditions.

- 2024 has good machinability, particularly when heat-treated.

Applications:

-

- 7050 is extensively used in aerospace and military applications due to its high strength and resistance to stress-corrosion cracking.

- 6061 is versatile and used in a variety of structural and marine applications due to its good corrosion resistance and machinability.

- 7075 is commonly used in high-performance aerospace and sports equipment applications where maximum strength is required.

- 2024 is used in aerospace structures and high-strength applications, benefiting from its high strength and durability.

How Can I Get A Sample Of 7050 Aluminum Sheets?

To obtain our 7050 aluminum sheet metal samples, please contact HXM directly. We provide free samples for testing, customers only need to bear the shipping costs. Our team is always ready to assist you with any specific requirements and provide necessary technical support.

What are the Typical Tempers for 7050 Aluminum?

-

T6: Solution heat-treated and artificially aged for high strength and good fatigue resistance.

-

T651: Solution heat-treated, stress-relieved by stretching, and artificially aged for improved dimensional stability.

-

T73: Solution heat-treated, stress-relieved by stretching, and artificially aged for enhanced stress-corrosion resistance.

Is 7050 Aluminum Resistant to Corrosion?

7050 aluminum has good corrosion resistance but is not as corrosion-resistant as some other alloys like 6061. It is particularly susceptible to stress-corrosion cracking in certain environments. Proper coatings and maintenance can help improve its resistance.

Can 7050 Aluminum be Welded?

7050 aluminum can be welded, but it is more challenging compared to other alloys. Special techniques and precautions are necessary to avoid issues like heat-affected zone (HAZ) cracking. TIG welding is commonly used for welding 7050 aluminum.

Why Choose Us As Your 7050 Aluminum Plate Suppliers?

When selecting 7050 aluminum plate suppliers, it’s crucial to choose a partner that offers quality, reliability, and expertise. Here are compelling reasons why you should choose us as your 7050 aluminum sheet supplier:

High-Quality Products

- Certified Material: We provide 7050 aluminum sheets that meet stringent industry standards and specifications, ensuring high performance and durability.

- Rigorous Testing: Our products undergo comprehensive testing for mechanical properties, chemical composition, and surface quality to guarantee they meet or exceed your requirements.

Extensive Expertise and Experience

- Industry Knowledge: With years of experience in the aluminum industry, our team has the expertise to guide you in selecting the right product for your specific application.

- Technical Support: Our knowledgeable staff can provide technical support and advice on the processing, machining, and application of 7050 aluminum.

Competitive Pricing

- Cost-Effective Solutions: We offer competitive pricing without compromising on quality, providing you with value for your investment.

- Transparent Quotes: Receive clear and detailed quotes with no hidden costs, helping you manage your budget effectively.

Custom Solutions and Flexibility

- Custom Sizes and Tempers: We offer a range of sizes and tempers, including custom specifications, to meet your precise needs.

- Flexible Orders: Whether you need large quantities or small orders, we can accommodate your requirements and adjust to your schedule.

Reliable Delivery and Logistics

- Timely Delivery: We ensure prompt delivery of your orders, with reliable logistics and supply chain management to minimize downtime.

- Global Shipping: Our efficient shipping processes and international logistics capabilities enable us to serve customers worldwide.

Commitment to Customer Satisfaction

- Exceptional Service: We prioritize customer satisfaction by offering responsive support, addressing any concerns promptly, and ensuring a seamless ordering experience.

- After-Sales Support: Our commitment extends beyond the sale, providing ongoing support and assistance to ensure your needs are met even after delivery.

Sustainability and Compliance

- Environmental Responsibility: We adhere to sustainable practices and ensure that our products comply with environmental regulations.

- Quality Certifications: Our facilities and processes are certified to meet industry standards, reflecting our dedication to quality and compliance.

Innovative Solutions

- Advanced Technology: We utilize state-of-the-art technology and machinery to produce high-quality 7050 aluminum sheets that meet modern industry demands.

- Continuous Improvement: We invest in research and development to continuously enhance our products and services.