HXM is your trusted source for 3004 Aluminum Wire, a high-strength, corrosion-resistant aluminum alloy wire. Widely used across industries, this alloy combines excellent durability, formability, and conductivity, making it a preferred choice for demanding applications.

Whether searching for 3004 Aluminum Wire suppliers, comparing 3004 Aluminum Wire prices, or evaluating stock availability, HXM provides the quality and service you need.

3004 Aluminum Wire Specifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: H14, H18, O, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: ISO9001, CE, SGS, etc

Delivery Time: 7-20 days.

3004 Aluminum Wire Data Sheet

Equivalent Of Aluminum 3004 Wire

| Region/Country | Standard | Equivalent Name |

|---|---|---|

| United States | ASTM | 3004 Aluminum Alloy |

| Europe | EN | 3.0517 |

| China | GB | 3004 Aluminum Alloy |

| Japan | JIS | A3004 |

| International | ISO | Aluminum Alloy 3004 |

| South Korea | KS | A3004 |

| Australia | AS | 3004 Aluminum Alloy |

| India | IS | IS 737 Grade 3004 |

Chemical Composition of 3004 Aluminum Wire

The chemical composition of the 3004 aluminum wire is designed to provide a balance of strength, formability, and corrosion resistance. Here’s a detailed breakdown of the typical composition:

| Element | Percentage Range |

|---|---|

| Al | Balance (typically around 95.0% – 98.0%) |

| Mn | 1.0% – 1.5% |

| Cu | 0.3% – 0.7% |

| Mg | 0.0% – 0.2% |

| Si | 0.0% – 0.3% |

| Fe | 0.7% max |

| Cr | 0.0% – 0.1% |

| Zn | 0.0% – 0.1% |

| Others | Each 0.05% max, Total 0.15% max |

Mechanical Properties of 3004 Aluminium Wires with Different Tempers

| Temper | Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|---|

| 3004-O (Annealed) | 165 – 210 MPa (24 – 30 ksi) | 110 – 150 MPa (16 – 22 ksi) | 20% – 30% | 45 – 55 HB |

| 3004-H12 (Work-Hardened) | 210 – 270 MPa (30 – 39 ksi) | 150 – 200 MPa (22 – 29 ksi) | 12% – 20% | 55 – 70 HB |

| 3004-H14 (Half Hard) | 235 – 285 MPa (34 – 41 ksi) | 170 – 220 MPa (25 – 32 ksi) | 10% – 18% | 60 – 75 HB |

| 3004-H16 (Hard) | 260 – 310 MPa (38 – 45 ksi) | 190 – 240 MPa (28 – 35 ksi) | 8% – 15% | 65 – 80 HB |

| 3004-H18 (Extra Hard) | 275 – 325 MPa (40 – 47 ksi) | 210 – 260 MPa (30 – 38 ksi) | 6% – 12% | 70 – 85 HB |

For high-quality 3004 aluminum wires and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 3004 Aluminum Wires

O (Annealed): Best for applications where flexibility and formability are required.

H12: Suitable for applications needing a balance between strength and formability.

H14: Ideal for parts that need moderate strength and formability.

H16: Chosen for applications needing higher strength with less flexibility.

H18: Used where high strength is critical and some reduction in formability is acceptable.

Are you looking for competitive 3004 Aluminum Wire prices? HXM offers transparent and affordable rates for bulk orders. Contact us today to get a personalized quote.

Applications of 3004 Aluminum Wire Metal

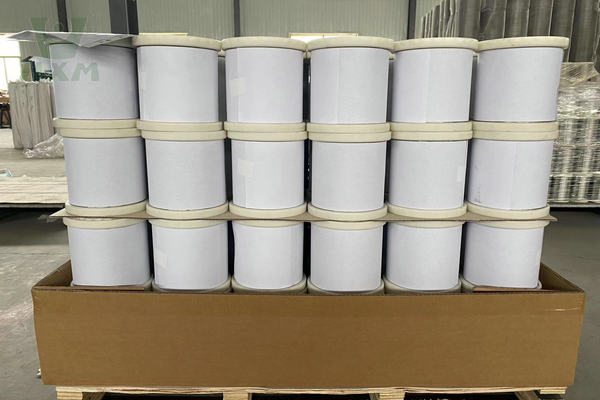

3004 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

Features of 3004 Aluminum Wire

Enhanced Corrosion Resistance: Performs well in harsh environments, including marine and industrial settings.

Superior Strength: Higher tensile strength compared to 3003 alloy.

Lightweight and Flexible: Ideal for lightweight structures and easy fabrication.

High Conductivity: Supports efficient electrical and thermal applications.

How does 3004 Aluminum Wire compare to 3003 alloy?

3004 has higher strength and similar corrosion resistance compared to 3003, making it suitable for more demanding applications.

Why Choose Us As Your 3004 Aluminum Wire Supplier?

Reliable Quality: Every batch meets industry standards for performance and safety.

Competitive Pricing: Get the best value for your investment.

Custom Options: Tailored specifications to suit your project needs.

Fast Delivery: Efficient shipping to ensure your projects stay on schedule.

Global Support: Assistance available wherever your business operates.