Looking for a reliable 3004 Aluminum Strip Supplier and Manufacturer? We are one of the outstanding aluminum strip manufacturers and suppliers in China, providing high-quality 3004 Aluminum Strips at competitive prices. We have an extensive stock of 3004 Aluminum strips to ensure timely delivery for all your needs. Whether you are in the construction, packaging, or automotive industries, our 3004 Aluminum Strip can meet your requirements.

Contact us for more detailed information about 3004 aluminum strips, the services we provide, and our stocks.

3004 Aluminium Strip Specifications

Standards : EN 541, EN 573-3, YS/T435-2009, GB/T 3190, GB/T3880.1-2006

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

3004 Aluminum Strip Data Sheet

Equivalent Of Aluminum 3004 Strip

| Region/Country | Standard | Equivalent Name |

|---|---|---|

| United States | ASTM | 3004 Aluminum Alloy |

| Europe | EN | 3.0517 |

| China | GB | 3004 Aluminum Alloy |

| Japan | JIS | A3004 |

| International | ISO | Aluminum Alloy 3004 |

| South Korea | KS | A3004 |

| Australia | AS | 3004 Aluminum Alloy |

| India | IS | IS 737 Grade 3004 |

Chemical Composition of 3004 Aluminum Strip

The chemical composition of the 3004 aluminum strip is designed to provide a balance of strength, formability, and corrosion resistance. Here’s a detailed breakdown of the typical composition:

| Element | Percentage Range |

|---|---|

| Al | Balance (typically around 95.0% – 98.0%) |

| Mn | 1.0% – 1.5% |

| Cu | 0.3% – 0.7% |

| Mg | 0.0% – 0.2% |

| Si | 0.0% – 0.3% |

| Fe | 0.7% max |

| Cr | 0.0% – 0.1% |

| Zn | 0.0% – 0.1% |

| Others | Each 0.05% max, Total 0.15% max |

Mechanical Properties of 3004 Aluminium Strips with Different Tempers

| Temper | Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|---|

| 3004-O (Annealed) | 165 – 210 MPa (24 – 30 ksi) | 110 – 150 MPa (16 – 22 ksi) | 20% – 30% | 45 – 55 HB |

| 3004-H12 (Work-Hardened) | 210 – 270 MPa (30 – 39 ksi) | 150 – 200 MPa (22 – 29 ksi) | 12% – 20% | 55 – 70 HB |

| 3004-H14 (Half Hard) | 235 – 285 MPa (34 – 41 ksi) | 170 – 220 MPa (25 – 32 ksi) | 10% – 18% | 60 – 75 HB |

| 3004-H16 (Hard) | 260 – 310 MPa (38 – 45 ksi) | 190 – 240 MPa (28 – 35 ksi) | 8% – 15% | 65 – 80 HB |

| 3004-H18 (Extra Hard) | 275 – 325 MPa (40 – 47 ksi) | 210 – 260 MPa (30 – 38 ksi) | 6% – 12% | 70 – 85 HB |

For high-quality 3004 aluminum coils and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 3004 Aluminum Strips

3004 aluminum strip is available in various tempers, each offering distinct mechanical properties and suitability for different applications. Here’s an overview of the most common tempers for 3004 aluminum strips:

3004-H14: Medium strength, good machinability, suitable for applications such as roof panels and curtain walls that require a balance between strength and formability.

3004-H18: High strength, lower machinability, suitable for rigid applications such as structural parts that require high strength.

3004-H24: Slightly stronger than H14, good machinability, suitable for applications such as automotive panels and storage tanks.

3004-O state: The softest state, excellent machinability, suitable for deep-drawn parts with complex shapes such as beverage cans and kitchenware.

3004-H32: Balanced strength and formability, suitable for various parts in the automotive industry.

Applications of 3004 Aluminum Strip Metal

3004 aluminum strip is widely used in industries such as automotive, packaging, construction, and manufacturing. Typical applications include:

Automotive Panels: Due to its combination of strength and formability.

Beverage Cans: Often used in the production of cans and lids.

Roofing and Siding: Utilized in building materials for its corrosion resistance.

Cooking Utensils: Found in cookware due to its ability to withstand high temperatures and resist corrosion.

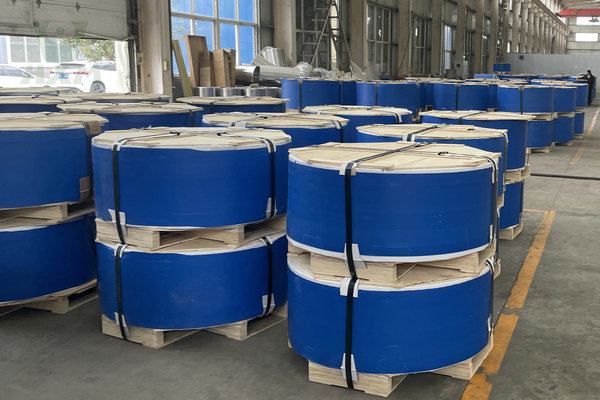

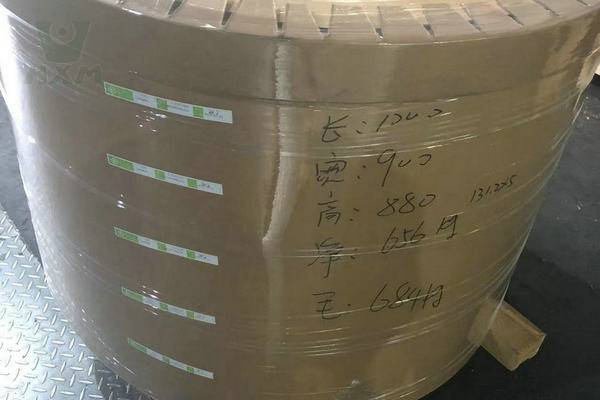

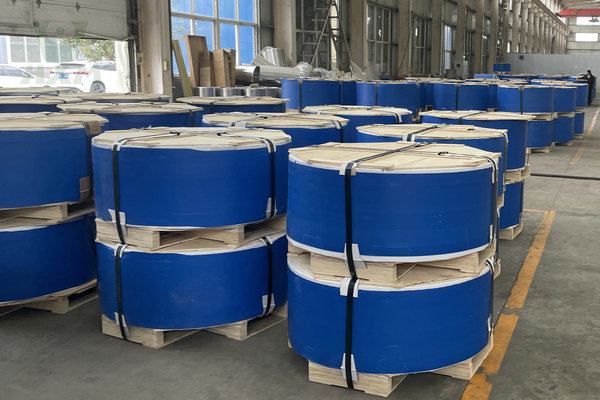

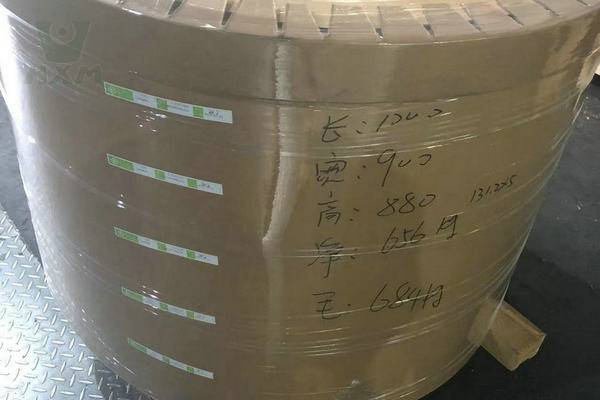

3004 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 3004 Aluminum Strip?

3004 Aluminum Strip is a versatile and durable aluminum alloy that belongs to the 3000 series and is known for its excellent corrosion resistance, moderate strength, and good formability. 3004 Aluminum Strip is composed primarily of aluminum, with manganese as the main alloying element and a small amount of magnesium. This combination enhances its strength compared to the more commonly used 3003 alloys while maintaining good machinability.

3000 Series Aluminum

Features of 3004 Aluminum Strip:

Alloy Series: 3000 Series

- Corrosion Resistance: Offers excellent corrosion resistance, making it suitable for outdoor and marine applications.

Strength: Provides higher strength than 3003 aluminum, making it suitable for applications requiring moderate strength.

Formability: Can be easily formed, bent, and shaped, making it ideal for complex shapes and deep-drawing processes.

Weldability: 3004 aluminum strip can be welded using common welding methods, which adds to its versatility in various fabrication processes.

How to Choose the Right 3004 Aluminum Strip?

Application Requirements: Choose the appropriate thickness, width, and mechanical properties according to your specific application scenarios (such as cans, bottle caps, building materials, etc.).

Specifications: The common 3004 aluminum narrow strip thickness range is 0.15mm-10.0mm, and the width can be customized according to demand. Make sure the selected specifications meet your processing requirements.

Surface Treatment: Choose whether to use coating, anodizing, and other surface treatments according to the use environment to improve corrosion resistance or aesthetics.

Quality Standards: Confirm whether the product meets international standards (such as ASTM, GB/T, etc.), and check the quality certification documents provided by the aluminum narrow strip supplier.

Supplier Reputation: Choose a 3004 aluminum narrow strip supplier with a good reputation and after-sales service guarantee to ensure product quality and delivery cycle.

If you are not sure how to choose, you can contact our professional team and we will provide customized suggestions based on your needs.

3004 Aluminum Strip VS Other Aluminum Strip:

| Attribute | 3004 Aluminum Strip | 1050 Aluminum Strip | 5052 Aluminum Strip | 6061 Aluminum Strip | 7075 Aluminum Strip |

|---|---|---|---|---|---|

| Composition | Al, Mn (1.0-1.5%), Mg (0.8-1.3%) | Al (99.5%) | Al, Mg (2.2-2.8%), Cr | Al, Mg, Si | Al, Zn, Mg, Cu |

| Strength | Moderate | Low | Medium to High | High | Very High |

| Corrosion Resistance | Excellent | Excellent | Excellent (especially in marine environments) | Good (better with anodizing) | Moderate (usually requires coating) |

| Formability | Good, easy to form | Excellent, very easy to form | Good, suitable for welding and forming | Good, suitable for machining and welding | Good, but limited for complex shapes |

| Weldability | Good | Excellent | Excellent | Good | Poor |

| Typical Applications | Beverage cans, automotive panels, roofing | Chemical and food processing, electrical applications | Marine components, pressure vessels | Structural applications, aerospace | High-performance parts, aerospace |

| Price Comparison | Moderate | Low | Medium to High | High | Very High |

How Can I Get A Sample Of 3004 Aluminum Strips?

Please contact us directly and send us the material, specification, quantity and delivery address of the samples you need.

Where can I Buy High-Quality 3004 Aluminum Strip?

To buy high-quality 3004 aluminum strips, it is recommended to choose the following channels:

Use Google Chrome to find professional aluminum suppliers: Choose companies that focus on aluminum production and sales to ensure that the products meet international standards (such as ASTM, GB/T, etc.).

Brand manufacturers: Well-known brands usually have a strict quality control system and can provide stable and high-quality products.

Online platforms: Find certified suppliers through reliable B2B platforms (such as Alibaba, and Global Sources), and check customer reviews and transaction records.

Local dealers: Contact local aluminum dealers to conduct on-site inspections of product quality and inventory.

Recommended to choose our company: We focus on the production and sales of 3004 aluminum strips, with advanced production equipment and strict quality inspection processes to ensure that each roll of aluminum strips meets customer needs. We also provide customized services to meet the special requirements of different industries. Welcome to contact us for more information and free samples!

What are the Advantages of Using 3004 Aluminum Strip in Can Manufacturing?

High Strength: The 3004 aluminum strip has excellent mechanical strength and can withstand the pressure of cans during filling, transportation, and use.

Good Formability: easy to stamp and stretch, suitable for manufacturing complex can structures such as can bodies and pull rings.

Excellent Corrosion Resistance: The 3004 aluminum strip has good corrosion resistance to acidic or alkaline components in beverages, ensuring that cans are stored for a long time without deterioration.

Lightweight: Aluminum has low density, and cans made of 3004 aluminum strips are light in weight, and easy to transport and carry, while reducing carbon emissions.

Recyclability: 3004 aluminum strip is 100% recyclable, meets environmental protection requirements, and promotes sustainable development.

Therefore, the 3004 aluminum strip is widely used in industries such as beer, carbonated beverages, and food packaging. If you have any other questions, you can contact us directly.

Arabic

Arabic Bulgarian

Bulgarian Dutch

Dutch English

English French

French German

German Indonesian

Indonesian Italian

Italian Japanese

Japanese Korean

Korean Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovenian

Slovenian Spanish

Spanish Thai

Thai