Are you looking for a reliable 3005 aluminum strip supplier? We provide customers with high-quality 3005 aluminum strips, and our 3005 aluminum strips are in stock with a wide range of varieties to meet various application needs. If you want information on 3005 aluminum strips for sale or want to know the latest 3005 aluminum strip prices, our professional team is always here to help you.

We look forward to being your trusted 3005 aluminum strip supplier and manufacturer, providing competitive prices and excellent product quality. Contact us now to get more product information and prices for 3005 aluminum strips.

3005 Aluminium Strip Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, etc.

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

Ready to place an order or request a custom quote? Contact our team today to get pricing for your 3005 aluminum bar needs.

3005 Aluminum Strip Data Sheet

Equivalent Of Aluminum 3005 Strip

| Country/Region | Standards Organization | Standard | Description |

|---|---|---|---|

| USA | ASTM | ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| Europe | EN | EN 485-2 | Aluminum and Aluminum Alloys – Sheet, Strip and Plate – Mechanical Properties |

| Japan | JIS | JIS H4000 | Aluminum and Aluminum Alloy Sheets and Plates |

| China | GB | GB/T 3880 | Aluminum and Aluminum Alloy Plates, Sheets, and Strips |

| Germany | DIN | DIN 1725 | Aluminum and Aluminum Alloys – Sheets and Plates |

| International | ISO | ISO 6361-2 | Wrought Aluminum and Aluminum Alloy Sheets, Strips, and Plates – Mechanical Properties |

Chemical Composition of 3005 Aluminum Strip

| Element | Al | Mn | Mg | Cu | Fe | Si | Zn | Cr | Other, each | Other, total |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 96.8 – 98.6 | 1.0 – 1.5 | 0.2 – 0.6 | ≤ 0.30 | ≤ 0.7 | ≤ 0.6 | ≤ 0.25 | ≤ 0.1 | ≤ 0.05 | ≤ 0.15 |

Notes:

Al: The remainder of the composition is aluminum.

Mn: Added to increase strength and hardness.

Mg: Improves the strength and workability.

Cu, Fe, Si, Zn, Cr: Present in controlled amounts to enhance specific properties and performance characteristics.

Other elements: Trace amounts of other elements are present, each limited to 0.05%, and the total cannot exceed 0.15%.

Mechanical Properties and Tempers of 3005 Aluminium Strip

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

| H12 | 130 – 170 | 90 – 110 | 12 – 14 | ~45 HB |

| H14 | 140 – 185 | 100 – 125 | 10 – 12 | ~46 HB |

| H16 | 150 – 195 | 110 – 135 | 8 – 10 | ~47 HB |

| H18 | 160 – 205 | 120 – 145 | 8 – 9 | ~48 HB |

| H22 | 130 – 175 | 95 – 115 | 12 – 14 | ~45 HB |

| H24 | 140 – 185 | 105 – 130 | 10 – 12 | ~46 HB |

| H26 | 150 – 195 | 115 – 140 | 8 – 10 | ~47 HB |

| H28 | 160 – 205 | 125 – 150 | 8 – 9 | ~48 HB |

| H32 | 130 – 170 | 90 – 115 | 12 – 14 | ~45 HB |

| H34 | 140 – 185 | 100 – 125 | 10 – 12 | ~46 HB |

| H36 | 150 – 195 | 110 – 135 | 8 – 10 | ~47 HB |

| H38 | 160 – 205 | 120 – 145 | 8 – 9 | ~48 HB |

For high-quality 3005 aluminum strip and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 3005 Aluminum Strips

3005 aluminum strip has a variety of different hardness and states, depending on its annealing, hardening, and cold working process. The following are the common states (or hardness) of 3005 aluminum strip and their characteristics:

3005-O (Annealed State)

Features: Fully annealed state, with maximum ductility and minimum strength.

Application: Suitable for applications requiring high plasticity and formability, such as deep drawing, stretch forming, and other processes.

3005-H12/H22

Features: Partially cold-work hardened, with medium strength and good plasticity.

Application: Commonly used in structural parts that require a certain strength, such as building materials, automobile bodies, etc.

3005-H14/H24

Features: After more cold-work hardening treatment, it has higher strength and lower ductility.

Application: Suitable for applications that require high strength and good corrosion resistance, such as roofing materials, curtain wall panels, etc.

3005-H18

Features: Fully cold-work hardened state, with the highest strength and lowest ductility.

Application: Suitable for applications that require high strength but not high plasticity, such as electronic product housings, building decoration materials, etc.

3005-H32/H34

Features: Provide moderate strength and good ductility by regulating cold working and low-temperature tempering.

Application: Commonly used in aerospace, transportation and storage equipment, and other fields that require balanced strength and ductility.

3005-H38

Features: Extreme cold working hardening, with very high strength.

Application: Used in applications with very high strength requirements, such as industrial components and structural materials.

3005 aluminum strips in different states have different performances in strength, ductility, and machinability. If you need to buy 3005 aluminum strips, you should choose the appropriate state according to the actual application requirements to ensure the best performance of the material during use. If you have any questions, you can contact us directly.

Applications of 3005 Aluminum Strip Metal

3005 aluminum strip is highly versatile and finds applications across various industries due to its specific properties and size advantages. Here are the primary industries where the 3005 strip is commonly used:

1. Electronics and Electrical Industry

- Electronic Components Manufacturing: The 3005 aluminum strip is used in making small electronic parts like connectors, lead frames, and grounding strips due to its excellent conductivity and formability.

- Transformer Windings: In power electronics, it is used in transformer windings to enhance efficiency and reduce energy losses.

2. Automotive Industry

- Body Trim: Due to its corrosion resistance and aesthetic appeal, the aluminum 3005 strip is widely used in automotive exterior trim, sealing strips, and window frames.

- Wiring Harness Protection: The strip is also employed to protect internal wiring harnesses, providing mechanical protection and electromagnetic shielding.

3. Building and Decorative Materials

- Decorative Strips and Edge Protection: In construction, 3005 strips are utilized for making decorative strips, edge protection strips, and window frame materials, ensuring durability and visual appeal.

- Curtain Wall Components: The strip is also used in curtain wall systems of high-rise buildings for small structural components and connectors.

4. Packaging Industry

- Food Packaging Strips: The 3005 aluminum strip is used to produce sealing strips, zipper tapes, and other packaging components in the food industry, valued for its non-toxicity, corrosion resistance, and easy formability.

- Flexible Packaging Material: It is also used as an inner layer in aluminum-plastic composite packaging, offering excellent barrier properties and mechanical strength.

5. Communications Equipment

- Antenna Components: The strip is used in making antennas and their components in communication devices, offering good conductivity and interference protection.

- Signal Shielding: The 3005 aluminum strip is also employed in creating signal shielding layers to prevent electromagnetic interference due to its excellent conductivity.

6. HVAC and Refrigeration Equipment

- Radiator and Condenser Fins: The 3005 strip is widely used in air conditioning and refrigeration equipment for radiator and condenser fins, thanks to its good thermal conductivity and corrosion resistance.

- Flexible Joints: It is also used in making flexible joints in refrigeration equipment, ensuring flexibility and sealing performance.

7. Consumer Electronics

- Battery Casings: The strip is used in manufacturing lithium battery casings for laptops, smartphones, and other consumer electronics, providing lightweight yet strong protection.

- Decorative Trim: The 3005 aluminum strip is often used as decorative trim and frame material in consumer electronics, enhancing the product’s appearance.

8. Pharmaceutical Industry

- Pharmaceutical Packaging: In the pharmaceutical industry, the 3005 aluminum strip is used in creating sealing materials for drug packaging, offering good sealing and moisture resistance to ensure the safety of medications.

The 3005 narrow aluminum strip is an ideal material for producing small structural components and precision parts across various industries, particularly where high corrosion resistance and good formability are required.

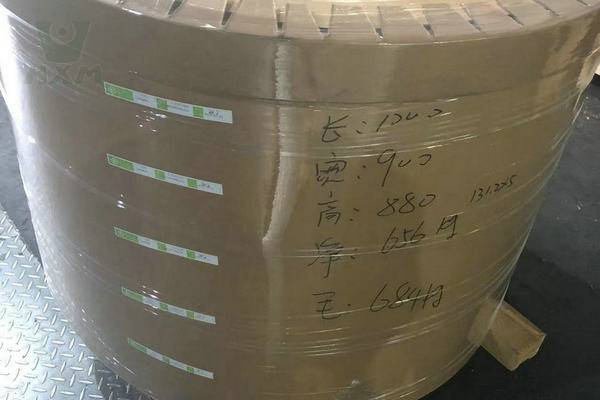

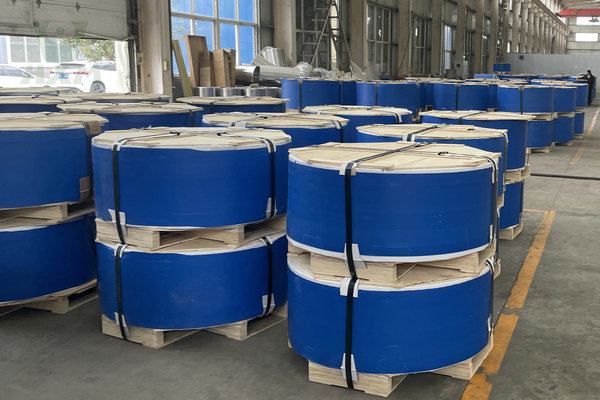

3005 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 3005 Aluminum Strip?

The 3005 aluminum strip is a specific type of aluminum alloy strip that belongs to the 3000 series of aluminum alloys. This series is primarily characterized by its moderate strength, excellent corrosion resistance, and good formability. The 3005 alloy, in particular, is an alloy of aluminum, manganese, and small amounts of magnesium, which enhances its properties for various industrial applications.

3000 Series Aluminum

Features of 3005 Aluminum Strip:

Alloy Series: 3000 Series Aluminum

Corrosion Resistance: 3005 aluminum strip is known for its excellent corrosion resistance, especially in marine environments. This makes it suitable for applications where the material is exposed to moisture or other corrosive agents.

Strength: The addition of manganese and magnesium provides a moderate increase in strength compared to pure aluminum. Although it is not as strong as 5000 or 6000 series alloys, it offers a good balance between strength and ductility.

Formability: The alloy has good formability, which means it can be easily shaped, bent, and fabricated into different forms without cracking. This makes it ideal for complex forming operations, including deep drawing and bending.

Weldability: 3005 aluminum strip can be welded using most standard welding techniques. However, proper care must be taken to avoid cracking and other welding defects.

Surface Finish: This alloy has a smooth surface finish, which can be further enhanced through various treatments such as anodizing, painting, or coating.

At Huaxiao Metal, we are committed to providing high-quality aluminum products and excellent customer service. With years of industry experience and a strong supply chain, we have become a trusted aluminum metal supplier for customers in North America, South America, and Europe. Our team is ready to answer any questions you may have about 3005 aluminum strip pricing or bulk orders.

For the best aluminum strip quality, competitive pricing, and exceptional service, choose Huaxiao Metal today!

3005 Aluminum Strip Price & Availability

At Huaxiao Metal, we offer competitive prices for 3005 aluminum strips. Our pricing is flexible depending on order volume, and we provide discounts for bulk purchases. Whether you’re sourcing material for a small project or a large-scale industrial operation, we ensure that you get the best deal.

For more 3005 strip details on prices and availability, please contact us or request a quote

3005 Aluminum Strip VS Other Aluminum Strip:

| Attribute | 3005 Aluminum Strip | 1050 Aluminum Strip | 5052 Aluminum Strip | 6061 Aluminum Strip | 7075 Aluminum Strip | 3105 Aluminum Strip |

|---|---|---|---|---|---|---|

| Composition | Al, Mn (1.0-1.5%), Mg (0.2-0.6%) | Al (99.5%) | Al, Mg (2.2-2.8%), Cr | Al, Mg, Si | Al, Zn, Mg, Cu | Al, Mn (0.3-0.8%) |

| Strength | Moderate | Low | Medium to High | High | Very High | Moderate to Low |

| Corrosion Resistance | Excellent | Excellent | Excellent (especially in marine environments) | Good (better with anodizing) | Moderate (usually requires coating) | Excellent |

| Formability | Good, easy-to-shape | Excellent, very formable | Good, suitable for welding and forming | Good, suitable for machining and welding | Good, suitable for machining, welding can be difficult | Good, suitable for forming |

| Typical Applications | Building materials, automotive parts, packaging | Electrical applications, chemical processing | Marine applications, fuel tanks, pressure vessels | Aerospace, automotive structural parts, construction | Aerospace, military, high-performance components | Residential siding, mobile homes, rain-carrying goods |

| Price Comparison | Moderate | Lowest | Medium to High | High | Highest | Moderate to Low |

How Can I Get A Sample Of 3005 Aluminum Strips?

Please contact us directly and send us the material, specification, quantity and delivery address of the samples you need.