5052 aluminum wire is a high-quality aluminum alloy product known for its superior strength, corrosion resistance, and versatility. Widely used in automotive, marine, construction, and electrical industries, 5052 aluminum wire stands out for its durability and adaptability in harsh environments.

Are you looking for a reliable 5052 aluminum wire supplier, manufacturer, or price? Please get in touch with us directly to give you the best service and product price, etc.

5052 Aluminum Wire Specifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: O, H32, H34, H36, H38, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: ASTM B221, B211, B316, B565 / ASME SB221, SB211, SB316, SB565, etc

Delivery Time: 7-20 days.

5052 Aluminum Wire Data Sheet

Equivalent Grades Of 5052 Aluminum Wire

Here’s a concise table showing the equivalent grades and standards for 5052 aluminum wires:

| Standard/Grade | Equivalent Grade | Key Features | Applications |

|---|---|---|---|

| 5052 (US Standard) | 5052 | Excellent corrosion resistance, good strength, and workability | Marine, automotive, construction |

| EN AW-5052 (European Standard) | EN AW-5052 | Same properties as 5052 | Same as 5052 |

| JIS A5052 (Japanese Standard) | JIS A5052 | Same properties as 5052 | Same as 5052 |

| GB 5052 (Chinese Standard) | GB 5052 | Same properties as 5052 | Same as 5052 |

Chemical Composition of 5052 Aluminum Wire

Here’s the chemical composition of the 5052 aluminum wire displayed in a horizontal table format using element symbols:

| Element | Al | Mg | Cr | Mn | Cu | Si | Fe | Zn | Other Elements |

|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | Balance | 2.2 – 2.8 | 0.15 – 0.35 | 0.10 – 0.50 | ≤ 0.10 | ≤ 0.25 | ≤ 0.40 | ≤ 0.10 | Each ≤ 0.05 |

Mechanical Properties of 5052 Aluminium Wires with Different Tempers

Temper | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

5052-O (Annealed) | 65 – 115 | 130 – 185 | 25 – 40 | 30 – 50 |

5052-H32 | 210 – 250 | 260 – 300 | 12 – 20 | 60 – 80 |

5052-H34 | 230 – 260 | 270 – 310 | 10 – 18 | 65 – 85 |

5052-H36 | 240 – 270 | 280 – 320 | 8 – 16 | 70 – 90 |

5052-H38 | 250 – 280 | 290 – 330 | 6 – 14 | 75 – 95 |

For high-quality 5052 aluminum wires and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 5052 Aluminum Wire Metal

O (Annealed): This temper provides the highest ductility and lowest strength. It is used in applications requiring good formability and minimal strength.

H32: Offers a balance between strength and ductility. It is used in applications where moderate strength and good formability are required.

H34: Provides higher strength compared to H32 with slightly lower ductility. Suitable for applications requiring increased strength.

H36: Further increased strength and reduced ductility compared to H34. Used in applications needing high strength and some degree of formability.

H38: The highest strength temper, with reduced elongation. It is used in applications where maximum strength is critical.

5052 Aluminum Coil Application

Automotive Industry

- Used in electrical wiring, connectors, and lightweight components to improve fuel efficiency.

Marine Industry

- Perfect for saltwater-exposed components like cables and rigging.

Construction

- Utilized in architectural frameworks and tensioned wire structures.

Electrical and Electronics

- Applied in conductors, coils, and cable shielding.

Industrial Manufacturing

- Common in machinery and equipment requiring high strength and corrosion resistance.

Looking for reliable 5052 aluminum wire manufacturers or suppliers? Contact HXM today for premium-quality aluminum wire at the best prices.

- Get a free quote for your project.

- Inquire about stock availability and customization options.

- Enhance your applications with durable, high-performance aluminum wire.

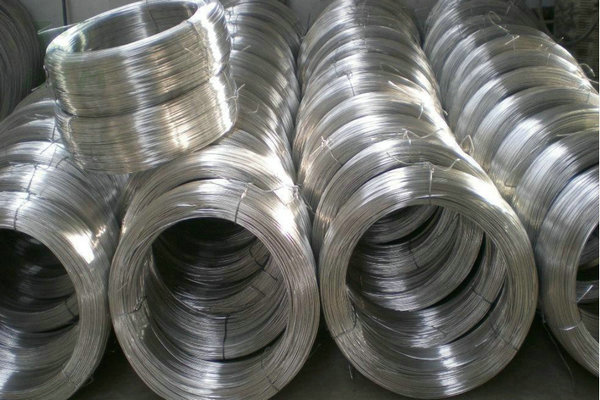

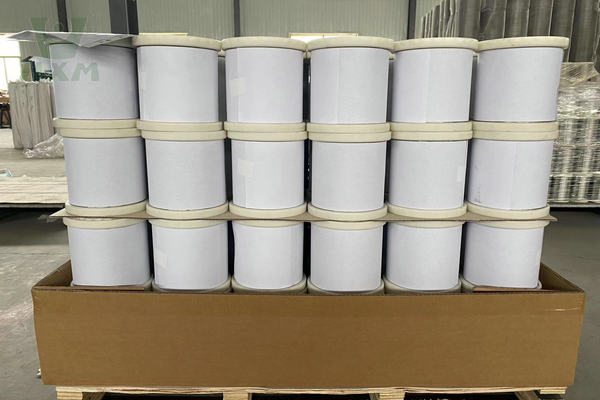

5052 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 5052 Aluminum Wire?

5052 aluminum wire is an alloy composed primarily of aluminum, with small amounts of magnesium and chromium to enhance its corrosion resistance and strength. It is highly valued for its light weight and excellent performance in harsh conditions, such as exposure to salt water or industrial chemicals.

5052 Aluminum Wire vs Other Alloys:

| Property | 5052 Aluminum Wire | 6061 Aluminum Wire | 1350 Aluminum Wire |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Moderate |

| Strength | High | Very High | Low |

| Weldability | Excellent | Good | Moderate |

Features of 5052 Aluminum Wire:

Superior Corrosion Resistance

- Performs exceptionally well in marine and industrial environments.

High Strength-to-Weight Ratio

- Ideal for applications requiring lightweight yet durable materials.

Excellent Formability

- Suitable for complex shaping and forming processes.

Outstanding Weldability

- Compatible with various welding techniques for seamless integration into assemblies.

Electrical Conductivity

- Offers good conductivity, making it a popular choice for electrical applications.

Why Choose Us As Your 5052 Aluminum Wire Supplier?

At HXM, we are dedicated to providing high-quality 5052 aluminum wire. As one of the leading manufacturers and suppliers, we ensure:

Competitive Prices: Cost-effective solutions for bulk and small orders.

Extensive Inventory: Immediate availability to meet project timelines.

Customization Options: Tailored sizes, tempers, and finishes to suit your application.

Reliability in Harsh Environments

Designed to withstand extreme weather and chemical exposure.

Cost-Effectiveness

Offers long-term durability, reducing replacement and maintenance costs.

Sustainability

Fully recyclable, aligning with eco-friendly manufacturing practices.