5056 aluminum wire is a high-strength, corrosion-resistant aluminum alloy used in a wide range of industries that require durability and excellent mechanical properties. The alloy is primarily composed of aluminum and magnesium and has excellent resistance to marine and chemical environments, among other properties.

If you have questions about 5056 aluminum wire prices, specifications, or bulk orders, contact us today!

5056 Aluminum Wire Specifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: O, T1, T3, T4, T5, T7, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: BS 3 L58 Alloy 5056, AMS 4182 5056-O Wire, QQ-A-430 5056-O Rivet wire, etc.

Delivery Time: 7-20 days.

5056 Aluminum Wire Data Sheet

Chemical Composition of 5056 Aluminum Wire

| Element | Range (%) |

|---|---|

| Al | Balance |

| Mg | 4.5 – 5.5 |

| Cr | 0.05 – 0.20 |

| Fe | ≤ 0.7 |

| Cu | ≤ 0.10 |

| Mn | ≤ 0.10 |

| Si | ≤ 0.30 |

| Zn | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

There are some differences in the chemical composition of aluminum products from different aluminum manufacturers, but they are all within a certain range. If you want to know more, please contact us directly!

Mechanical Properties of 5056 Aluminum Wire

| Property | Temper O | Temper H12 | Temper H14 | Temper H16 | Temper H18 |

|---|---|---|---|---|---|

| Tensile Strength | 310 MPa (45 ksi) | 345 MPa (50 ksi) | 379 MPa (55 ksi) | 414 MPa (60 ksi) | 450 MPa (65 ksi) |

| Yield Strength | 275 MPa (40 ksi) | 310 MPa (45 ksi) | 345 MPa (50 ksi) | 379 MPa (55 ksi) | 414 MPa (60 ksi) |

| Elongation | 12% | 10% | 8% | 7% | 6% |

| Brinell Hardness | 90 | 100 | 110 | 115 | 120 |

Choose us for reliable 5056 Aluminum Wire solutions that meet your specific needs with precision and quality.

Physical Properties of 5056 Aluminum Wire

| Property | Temper O | Temper H12 | Temper H14 | Temper H16 | Temper H18 |

|---|---|---|---|---|---|

| Density | 2.65 g/cm³ | 2.65 g/cm³ | 2.65 g/cm³ | 2.65 g/cm³ | 2.65 g/cm³ |

| Melting Point | 610°C – 650°C | 610°C – 650°C | 610°C – 650°C | 610°C – 650°C | 610°C – 650°C |

| Thermal Conductivity | 122 W/m·K | 122 W/m·K | 122 W/m·K | 122 W/m·K | 122 W/m·K |

| Electrical Conductivity | 30% IACS | 30% IACS | 30% IACS | 30% IACS | 30% IACS |

| Modulus of Elasticity | 70 GPa | 70 GPa | 70 GPa | 70 GPa | 70 GPa |

| Coefficient of Thermal Expansion | 22.8 µm/m·°C | 22.8 µm/m·°C | 22.8 µm/m·°C | 22.8 µm/m·°C | 22.8 µm/m·°C |

Features of 5056 Aluminum Wire

Corrosion Resistance: Exceptional resistance to salt water and chemical exposure.

High Strength-to-Weight Ratio: Ensures durability while maintaining lightweight properties.

Excellent Weldability: Easily welded using conventional techniques.

Versatility: Adaptable for various industrial, marine, and electrical applications.

Applications of 5056 Wires

5056 wire is commonly used in:

Cable Manufacturing: This is for electrical wiring and communication cables due to its excellent conductivity.

Aerospace and Automotive: Structural components requiring lightweight and corrosion resistance.

Marine Industry: Ideal for rigging, fishing nets, and other maritime equipment.

Industrial Applications: Used in rivets, fasteners, and hardware exposed to harsh conditions.

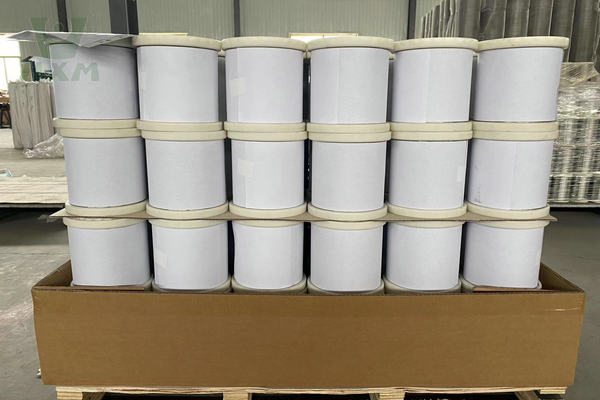

5056 Aluminium Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.