5083 Aluminum Strip Suppliers and Manufacturers in China

We are a leading domestic supplier and manufacturer of 5083 aluminum strips, committed to providing customers with high-performance aluminum products. 5083 aluminum strips are widely used in the fields of ships, automobiles, and chemical equipment due to their excellent corrosion resistance, strength, and good weldability. We not only have advanced production technology and equipment but also ensure the stability and reliability of our products through a strict quality management system.

We have a large inventory of aluminum strips and fast delivery. Please feel free to consult us for the latest quotes and supply information on our products.

5083 Aluminium Strip Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

5083 Aluminum Strip Data Sheet

Equivalent Grades Of Aluminum Strip 5083

| Standard | Equivalent Grade |

|---|---|

| ASTM (American) | ASTM B209 5083 |

| EN (European) | EN AW-5083 |

| DIN (German) | DIN 3.3547 |

| JIS (Japanese) | JIS A5052 (similar) |

| ISO (International) | ISO 209-1 (similar) |

Chemical Composition of Aluminum Strip 5083

| Al | Mg | Mn | Cr | Cu | Zn | Si | Fe |

|---|---|---|---|---|---|---|---|

| Balance | 4.0% – 4.9% | 0.40% – 0.70% | 0.05% – 0.25% | ≤ 0.10% | ≤ 0.10% | ≤ 0.10% | ≤ 0.40% |

Mechanical Properties of 5083 Aluminium Strip with Different Tempers

| Temper | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

5083 O (Soft) | 110 – 140 | 250 – 290 | 18 – 25 | 60 – 80 |

| 5083-H111 (H1) | 140 – 180 | 290 – 320 | 15 – 20 | 80 – 100 |

| 5083-H112 (H2) | 150 – 190 | 320 – 350 | 15 – 20 | 80 – 100 |

| 5083-H116 | 170 – 220 | 330 – 350 | 12 – 15 | 90 – 110 |

| 5083-H321 | 170 – 220 | 330 – 350 | 12 – 15 | 90 – 110 |

For high-quality 5083 aluminum strip and professional assistance, contact HXM, your reliable supplier of aluminum products.

Physical Properties of 5083 Aluminum Strip Metal

| Property | Value |

|---|---|

| Density | Approximately 2.66 g/cm³ (2660 kg/m³) |

| Melting Point | 650 – 660°C (1202 – 1220°F) |

| Thermal Conductivity | About 120 W/m·K |

| Electrical Conductivity | Approximately 30% IACS (International Annealed Copper Standard) |

| Specific Heat Capacity | About 900 J/kg·K (0.215 BTU/lb·°F) |

| Young’s Modulus | 70 – 72 GPa (10,000 – 10,500 ksi) |

| Thermal Expansion Coefficient | Approximately 23 x 10⁻⁶ /K |

| Sound Velocity | Approximately 6400 m/s (21,000 ft/s) |

Huaxiao Metal is a professional 5083 Aluminum Strip supplier and manufacturer. We are committed to providing high-quality aluminum alloy products to customers around the world. Contact us now to get 5083 Aluminum Narrow Strip prices, stock, and more!

Different Tempers of 5083 Aluminum Strips Metal

| Temper | Properties | Applications |

|---|---|---|

| O | Softest form with maximum ductility and lowest strength | Used for applications requiring high formability, such as deep drawing and bending; minimal residual stress applications |

| H111 | Solution heat-treated and partially strain-hardened, offering a balance of strength and ductility | Suitable for general-purpose applications requiring moderate strength and good formability, such as marine and automotive parts |

| H32 | Strain-hardened and solution heat-treated, providing high strength with good ductility | It is ideal for structural applications needing high strength and good formability, such as marine structures and pressure vessels |

| H34 | Further strain-hardened compared to H32, offering higher strength with reduced ductility | Used in applications requiring high strength and reduced formability, such as heavy-duty marine and structural components |

| H116 | Specially treated for superior resistance to stress-corrosion cracking, with good strength and ductility | Specifically used in marine environments where stress-corrosion resistance is critical, such as in shipbuilding and offshore structures |

Huaxiao Metal – Your Trusted 5083 Aluminum Strip Supplier and Manufacturer!

You can choose from many tempers, such as H111, H112, H116, H321, etc., to ensure the best performance of the material in different application scenarios. As a reliable 5083 aluminum strip supplier, we have a complete inventory management system and can deliver quickly. Inquire now to get the latest 5083 aluminum strip stock information!

Applications of 5083 Aluminum Strip Metal

Marine Industry: Commonly used in shipbuilding and marine applications due to its superior corrosion resistance in saltwater environments. Applications include boat hulls, decks, and other marine structures.

Aerospace: Utilized in aircraft structures where high strength and corrosion resistance are required.

Automotive: Used in high-performance automotive parts where strength and durability are important.

Pressure Vessels: Employed in pressure vessel manufacturing due to its ability to withstand high pressure and harsh conditions.

Construction: Applied in architectural elements and structural components where both strength and weather resistance are needed.

As a professional 5083 Aluminum Strip supplier and manufacturer, Huaxiao Metal offers a variety of specifications and stock options to meet the needs of manufacturers in different industries.

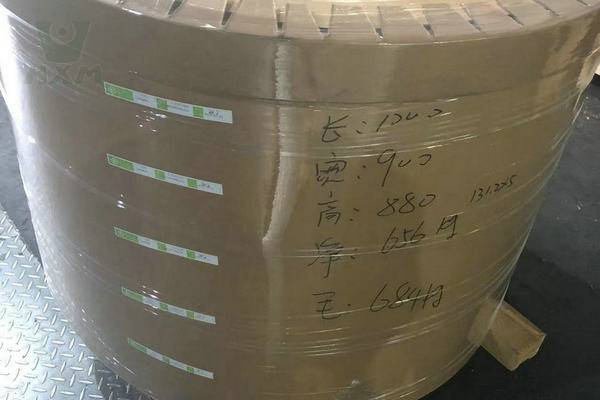

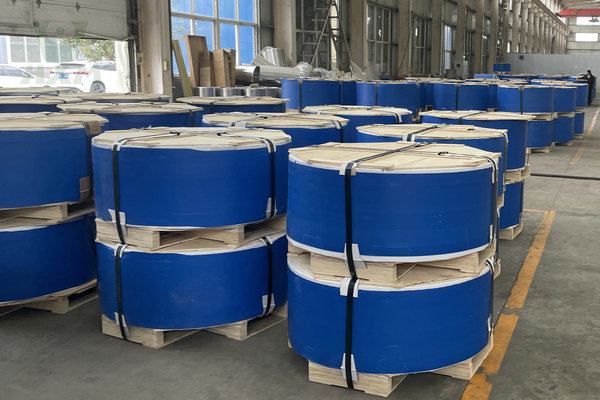

5083 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 5083 Aluminum Strip?

5083 aluminum strip is a type of aluminum alloy strip primarily known for its excellent corrosion resistance, high strength, and good weldability. It falls under the 5000 series of aluminum alloys, which are characterized by their high magnesium content.

5000 Series Aluminum

5083 Aluminum Strip Compare To Other Aluminum Strip?

| Property | 5083 Aluminum Strip | 6061 Aluminum Strip | 3003 Aluminum Strip | 5052 Aluminum Strip |

|---|---|---|---|---|

| Composition | Primarily aluminum with 4.0-4.9% magnesium, and small amounts of chromium | Aluminum alloyed with 0.8-1.2% magnesium and 0.4-0.8% silicon | Aluminum alloyed with 1.2-1.5% manganese | Aluminum alloyed with 2.2-2.8% magnesium and small amounts of chromium |

| Strength | High strength, especially in marine environments | High strength, can be heat-treated for enhanced properties | Lower strength compared to 5083, good for general applications | Good strength, higher than 3003 but lower than 5083 and 6061 |

| Corrosion Resistance | Excellent, especially in marine environments | Good, but not as high as 5083 or 5052 | Good, but less resistant than 5083 and 5052 | Excellent, particularly in marine environments |

| Weldability | Good weldability | Excellent weldability, often used in welded structures | Good weldability, used in applications that require high formability | Good weldability, suitable for welding and forming |

| Ductility | Good ductility, suitable for forming and shaping | Good ductility, can be heat-treated for various properties | Excellent ductility, highly formable | Good ductility, but less so than 3003 |

| Applications | Marine structures, aerospace, automotive, pressure vessels, construction | Aerospace, structural components, automotive, general engineering | Kitchenware, chemical equipment, general-purpose items | Marine applications, automotive fuel tanks, pressure vessels |

How Can I Get A Sample Of 5083 Aluminum Strips?

Yes, we can provide samples of 5083 aluminum strips for your testing. We can also provide samples of other materials. If you are unsure whether 5083 or other materials of aluminum strips meet your project requirements, you can contact us to get a sample.

Why Choose Us As Your 5083 Aluminum Strip Supplier?

If you are looking for a manufacturer and exporter of 5083 Aluminum Strip, I think we can be one of your Aluminum Strip suppliers! Here are some reasons why we think you can choose us:

Industry Time: We have been engaged in the metal industry for more than 10 years, with a professional manufacturing and export service team, advanced machinery and equipment, etc.

Competitive Product Prices: Due to our long history in this industry, we have long-term cooperation projects with many steel mills, so the quality and price of our products can be guaranteed. Our internal manufacturing efficiency has been improved, and we can produce more and better aluminum products in the same amount of time, thereby reducing our cost prices.

Excellent Customer Service: For first-time customers, we provide videos and on-site factory visits to increase customer trust. We accept payment methods such as TT, L/C, etc. The product warranty period is 5 years, etc.

Why not give us a chance to serve your project? I believe we can become one of your best and most trusted aluminum strip suppliers!