As a leading 5052 aluminum sheet supplier, we are committed to providing you with the best quality 5052 aluminum sheet on the market to meet your needs in different application fields. Whether you are looking for cost-effective 5052 aluminum sheet prices or want to understand the latest market trends of 5052 aluminum sheets, we can provide detailed information and professional advice.

Our 5052 aluminum sheet is widely used in industries such as shipbuilding, automobiles, and construction due to its excellent corrosion resistance, strength, and processing performance. Browse our 5052 aluminum sheet supply information now, find the 5052 aluminum sheet sales options you need, and enjoy the most competitive prices in the industry.

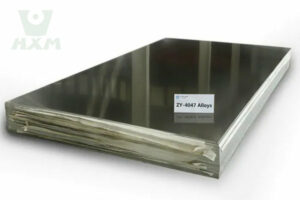

5052 Aluminium Sheets Specifications

Standards: ASTM, ASME, AMS, GB/T, JIS

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: O, H32, H34, H36, H38, etc.

Delivery Time: 7-20 days.

5052 aluminum plate is a typical Al-Mn alloy with low plasticity, good corrosion resistance, good formability, weldability, corrosion resistance, and good weldability.

5052 Aluminum Sheet Data Sheet

Equivalent Grades Of 5052 Aluminum Plates

Here’s a concise table showing the equivalent grades and standards for 5052 aluminum plates:

| Standard/Grade | Equivalent Grade | Key Features | Applications |

|---|---|---|---|

| 5052 (US Standard) | 5052 | Excellent corrosion resistance, good strength, and workability | Marine, automotive, construction |

| EN AW-5052 (European Standard) | EN AW-5052 | Same properties as 5052 | Same as 5052 |

| JIS A5052 (Japanese Standard) | JIS A5052 | Same properties as 5052 | Same as 5052 |

| GB 5052 (Chinese Standard) | GB 5052 | Same properties as 5052 | Same as 5052 |

Chemical Composition of 5052 Aluminum Plate

Here’s the chemical composition of the 5052 aluminum sheet displayed in a horizontal table format using element symbols:

| Element | Al | Mg | Cr | Mn | Cu | Si | Fe | Zn | Other Elements |

|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | Balance | 2.2 – 2.8 | 0.15 – 0.35 | 0.10 – 0.50 | ≤ 0.10 | ≤ 0.25 | ≤ 0.40 | ≤ 0.10 | Each ≤ 0.05 |

Mechanical Properties of 5052 Aluminium Sheets with Different Tempers

Temper | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

5052-O (Annealed) | 65 – 115 | 130 – 185 | 25 – 40 | 30 – 50 |

5052-H32 | 210 – 250 | 260 – 300 | 12 – 20 | 60 – 80 |

5052-H34 | 230 – 260 | 270 – 310 | 10 – 18 | 65 – 85 |

5052-H36 | 240 – 270 | 280 – 320 | 8 – 16 | 70 – 90 |

5052-H38 | 250 – 280 | 290 – 330 | 6 – 14 | 75 – 95 |

For high-quality 5052 aluminum sheets and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 5052 Aluminum Sheet Metal

O (Annealed): This temper provides the highest ductility and lowest strength. It is used in applications requiring good formability and minimal strength.

H32: Offers a balance between strength and ductility. It is used in applications where moderate strength and good formability are required.

H34: Provides higher strength compared to H32 with slightly lower ductility. Suitable for applications requiring increased strength.

H36: Further increased strength and reduced ductility compared to H34. Used in applications needing high strength and some degree of formability.

H38: The highest strength temper, with reduced elongation. It is used in applications where maximum strength is critical.

Applications of 5052 Aluminum Sheet Metal

Construction:

Automotive Industry:

Marine Industry: 5052 aluminum is commonly used for boat hulls and decks due to its superior resistance to saltwater corrosion. It’s also used for marine hardware such as fittings and fasteners.

Aerospace Industry: In aerospace applications, 5052 aluminum is used for various parts including fuel tanks, due to its high strength and resistance to corrosive environments.

Chemical Processing: 5052 aluminum is used in chemical storage tanks and pipes due to its resistance to corrosion from chemicals and acids, ensuring durability and safety.

Marine Transportation: The alloy is used for marine enclosures and sea containers, where high durability and resistance to harsh environmental conditions are necessary.

Industrial Equipment: It is utilized in manufacturing covers and enclosures for machinery, as well as heat exchangers, thanks to its resistance to harsh conditions and excellent durability.

Recreational Vehicles: In RVs, 5052 aluminum is used for body panels and structural parts, benefiting from its lightweight nature and resistance to corrosion.

Consumer Goods: The alloy is used in appliances and furniture due to its appearance and durability. It’s also found in various household and kitchen items.

Defense: 5052 aluminum is used in military vehicles for armor plating and structural parts, where strength and resistance to environmental factors are critical.

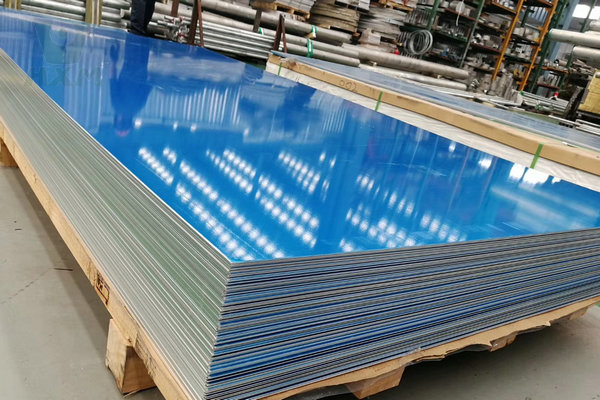

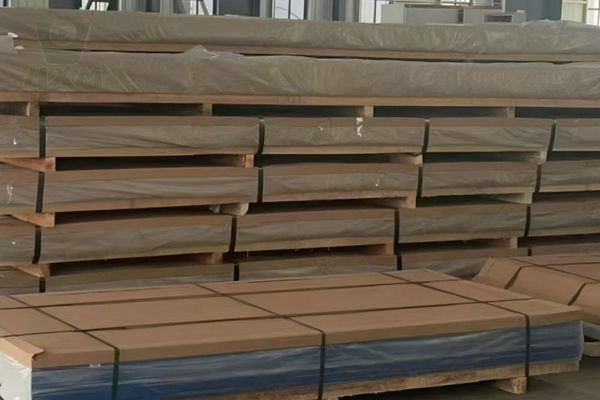

5052 Aluminum Sheet Packages

The following is our company’s conventional export packaging for aluminum plates. If you have special packaging requirements, our company can meet them. We very much hope to become one of your aluminum plate suppliers!

FAQ

What Is 5052 Aluminum Sheet?

5052 aluminum plate is an aluminum alloy known for its excellent corrosion resistance, high strength and good machinability. It is mainly composed of aluminum, magnesium is its main alloying element, and there are small amounts of chromium and other elements.

How Does 5052 Aluminum Compare To Other Aluminum Alloy?

5052 vs. 6061 Aluminum

-

Corrosion Resistance: 5052 has superior corrosion resistance compared to 6061, particularly in marine environments.

-

Strength: 6061 typically has higher tensile strength and yield strength compared to 5052, making it suitable for structural applications where higher strength is required.

-

Workability: 5052 is generally easier to form and weld compared to 6061, which can be more challenging to work with due to its higher strength.

-

Applications: 6061 is often used in aerospace, automotive, and structural applications, while 5052 is favored for marine, chemical, and automotive parts requiring excellent corrosion resistance.

5052 vs. 3003 Aluminum

-

Corrosion Resistance: 5052 offers much better corrosion resistance than 3003, making it more suitable for harsh environments.

-

Strength: 5052 is significantly stronger than 3003. 3003 is a lower-strength alloy, often used where high strength is not critical.

-

Workability: Both alloys are good in terms of formability and machinability, but 5052 offers higher strength and better performance in applications where strength is more important.

-

Applications: 3003 is commonly used in cooking utensils, chemical tanks, and residential siding, whereas 5052 is used in marine applications, automotive fuel tanks, and other parts requiring greater strength and corrosion resistance.

5052 vs. 7075 Aluminum

-

Corrosion Resistance: 5052 has better corrosion resistance compared to 7075, which is more prone to corrosion and typically requires protective coatings.

-

Strength: 7075 is significantly stronger than 5052, offering high strength-to-weight ratios, which is why it’s often used in aerospace and military applications.

-

Workability: 7075 can be more difficult to machine and weld compared to 5052, which is easier to work with.

-

Applications: 7075 is used in aerospace, military, and high-stress applications due to its strength, while 5052 is preferred for applications requiring good corrosion resistance and moderate strength.

5052 vs. 2024 Aluminum

-

Corrosion Resistance: 5052 excels in corrosion resistance compared to 2024, which is more susceptible to corrosion and often requires coating or anodizing.

-

Strength: 2024 generally offers higher tensile and yield strength compared to 5052, making it suitable for applications requiring high strength.

-

Workability: 2024 can be more difficult to machine and weld than 5052, which has better workability.

-

Applications: 2024 is commonly used in aerospace structures and high-stress applications, while 5052 is used in marine environments, automotive applications, and other areas where corrosion resistance is crucial.

How Can I Get A Sample Of 5052 Aluminum Sheets?

Yes, we can provide free samples.

You can leave a message online or send me an email directly. Please send me the sample material specifications and address you need, and I will arrange for my colleagues to provide you with samples.

What Are the Key Considerations When Choosing 5052 Aluminum Sheet Suppliers?

-

Reputation and Experience: Choose suppliers with a solid track record in providing high-quality 5052 aluminum sheets and reliable customer service.

-

Product Range: Ensure the supplier offers a variety of 5052 aluminum sheet sizes and tempers to meet your specific needs.

-

Certifications: Verify if the supplier provides certification for their products, indicating they meet industry standards and specifications.

-

Pricing and Availability: Compare 5052 aluminum sheet prices from different suppliers to ensure competitive rates without compromising on quality.

-

Delivery and Support: Evaluate their delivery times and customer support services to ensure timely and efficient fulfillment of your orders.

How Can I Find the Best 5052 Aluminum Sheet Prices?

5052 aluminum sheet prices can vary based on several factors:

-

Thickness and Size: Prices can differ based on the sheet thickness and dimensions. Larger and thicker sheets generally cost more.

-

Quantity: Bulk orders might qualify for discounts, so consider ordering larger quantities if feasible.

-

Supplier and Location: Prices can vary between suppliers and geographic locations due to shipping and handling costs.

-

Market Conditions: Fluctuations in aluminum prices on the global market can impact the cost of 5052 aluminum sheets.

To find the best 5052 aluminum sheet prices:

-

Request Quotes: Obtain quotes from multiple aluminum metal suppliers to compare prices.

-

Check for Promotions: Look for any ongoing promotions or discounts that suppliers may offer.

-

Negotiate: Don’t hesitate to negotiate with suppliers, especially for large orders.

Where Can I Buy 5052 Aluminum Sheets For Sale?

To buy 5052 aluminum sheets for sale, follow these steps:

-

Online Retailers: Explore online marketplaces and aluminum suppliers that offer 5052 aluminum sheets. Many sites provide detailed product specifications and pricing.

-

Local Distributors: Contact local metal distributors and suppliers who stock 5052 aluminum sheets. They can offer immediate availability and personalized service.

-

Direct Manufacturers: Purchasing directly from manufacturers can sometimes offer better pricing and custom options for 5052 aluminum sheets.