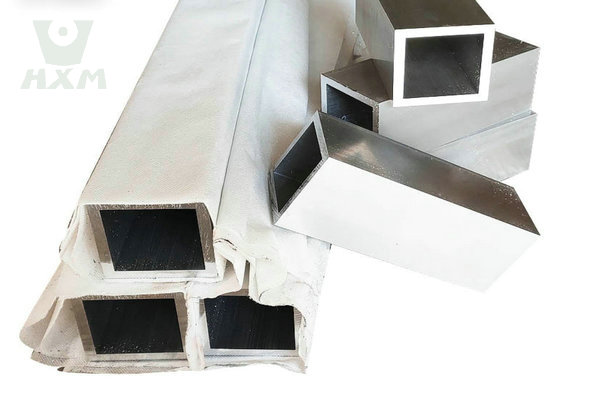

China 2011 Aluminum Tubes Suppliers & Manufacturers

2011 Aluminum tube is a widely used aluminum tube alloy material known for its excellent processing performance and high strength. It is especially suitable for applications requiring precision cutting. As a professional 2011 aluminum pipe supplier, we provide customers with 2011 aluminum pipes in various specifications to meet the needs of multiple industrial uses while offering competitive prices and flexible inventory options.

Contact us now to get the 2011 aluminum tube price and stock information.

2011 Aluminum Pipe & Tube Specifications

Standards: ASTM B210, ASTM B211, DIN 3.1056, QQ A-225/3, SAE J454, etc.

Thickness: 0.2-500mm, etc.

Width: 20-2650mm, etc.

Length: Customized

Shape: Round, Square, Rectangular, etc.

Material Temper: F, O, T3, T4, T6, T8, etc.

Delivery Time: 7-20 days.

2011 Aluminum Tube & Pipe Data Sheet

Equivalent Specifications of Aluminium 2011 Tube

here’s a table displaying the equivalent specifications of the Aluminum 2011 Tube:

| Specification | Standard/Organization | Details |

|---|---|---|

| EN | EN AW-2011 | European Norm equivalent for 2011 aluminum alloy |

| ASTM | ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| UNS | UNS A92011 | Unified Numbering System designation for 2011 aluminum |

| AA | AA2011 | Aluminum Association designation for 2011 alloy |

| ISO | ISO 6361 | International Organization for Standardization – Wrought aluminum and aluminum alloy sheets, strips, and plates |

| DIN | DIN 3.1655 | Deutsches Institut für Normung (German Institute for Standardization) equivalent for 2011 aluminum |

| JIS | JIS H 4000 | Japanese Industrial Standards for aluminum and aluminum alloys |

| GB | GB/T 3190 | National Standard of the People’s Republic of China for aluminum and aluminum alloy chemical composition |

| AMS | AMS 4027 | Aerospace Material Specification for 2011 aluminum alloy sheets and plates |

| SAE | SAE J454 | Society of Automotive Engineers – Wrought aluminum and aluminum alloy sheets and plates |

This table outlines the various standards and specifications that are equivalent to Aluminum 2011. If you would like more information, please contact us directly!

Chemical Composition of 2011 Aluminum Tube

Here is the chemical composition of the 2011 Aluminum Tube:

| Element | Composition (%) |

|---|---|

| Al | Balance |

| Cu | 5.0 – 6.0 |

| Fe | ≤ 0.7 |

| Si | ≤ 0.4 |

| Zn | ≤ 0.3 |

| Pb | 0.2 – 0.6 |

| Bi | 0.2 – 0.6 |

| Others | Each ≤ 0.05%, Total ≤ 0.15 |

This is the specific percentage range of various elements of the 2011 aluminum tube, which ensures its unique properties and performance characteristics. If you want to know more, please contact us directly!

Mechanical Properties of 2011 Aluminium Tube

| Property | Value |

|---|---|

| Ultimate Tensile Strength | 310 MPa (45 ksi) |

| Yield Strength | 276 MPa (40 ksi) |

| Elongation | Approximately 10% in 2 inches |

| Hardness | 95 HB |

| Modulus of Elasticity | 69 GPa (10,000 ksi) |

| Shear Strength | 207 MPa (30 ksi) |

The mechanical properties demonstrated above make the 2011 aluminum tube an excellent choice for applications that require high strength and precision machining. Its excellent machinability and ability to achieve a high-quality surface finish ensure its optimal performance in a variety of industrial uses.

For more information on the 2011 aluminum tube or to request a quote, please contact HXM. Our sales team will respond to you within 24 hours!

Physical Properties of 2011 Aluminum Tube

| Property | Value |

|---|---|

| Density | 2.85 g/cm³ (0.103 lb/in³) |

| Melting Point | 502 – 638°C (936 – 1180°F) |

| Thermal Conductivity | 121 W/m·K |

| Electrical Conductivity | 32% IACS |

| Coefficient of Thermal Expansion | 23.6 x 10⁻⁶ /°C (13.1 x 10⁻⁶ /°F) |

| Specific Heat Capacity | 0.87 J/g-°C |

These physical properties highlight the excellent thermal and electrical conductivity of the 2011 aluminum tube, as well as its suitability for high-temperature applications due to its melting point range and thermal expansion coefficient. Specific heat capacity and density further highlight the efficiency and reliability of this material.

For more details on 2011 aluminum tube, please contact HXM, our team will respond to you within 24 hours!

Tempers of 2011 Aluminum Tube

| Temper Designation | Description | Typical Applications |

|---|---|---|

| 2011-T3 | Solution heat-treated, cold-worked, and naturally aged. | Suitable for applications requiring high strength and good machinability. |

| 2011-T4 | Solution heat-treated and naturally aged. | General-purpose applications with a good balance of strength and ductility. |

| 2011-T6 | Solution heat-treated and artificially aged. | Offers the highest strength and is used in critical components where high performance is required. |

| 2011-T8 | Solution heat-treated, cold-worked, and artificially aged. | Provides excellent machinability and good strength, often used in complex, precision machined parts. |

| 2011-O | Annealed (softened). | Ideal for applications requiring maximum ductility and formability. |

These tempering treatments allow 2011 aluminum tube to be customized to specific application requirements, ensuring optimal performance in a variety of industrial and engineering environments.

For more information or pricing on 2011 aluminum tube, please contact HXM and our team will respond to your message within 24 hours!

Applications of 2011 Aluminum Pipe Metal

Electronics industry: used to manufacture connectors, conductive parts, electronic parts, etc.

Machining: suitable for the manufacture of high-precision parts, such as screws, nuts, washers, etc.

Automobile and transportation industry: 2011 aluminum tubes have a wide range of applications in automotive parts that require precision parts.

Instruments: These are widely used to manufacture precision instrument components that require multiple processing.

2011 aluminum tubes are widely used in precision parts processing, automation equipment, aerospace, automotive parts, the electronics industry, and fastener manufacturing due to their excellent cutting performance and good mechanical strength. Their good corrosion resistance and high conductivity also make them an ideal material for the production of electrical accessories and connectors. Whether it is mass production or customized needs, we can provide a variety of inventory and processing service specifications to meet the diverse needs of customers in different industries.

Contact us now to inquire about the price of 2011 aluminum tubes!

2011 Aluminum Pipe & Tube Packages

The following is our company’s standard aluminum pipe & tube export packaging. If the customer has any packaging requirements, our company can meet them.

As a professional 2011 aluminum tube supplier, we are committed to providing customers with the highest quality products and excellent customer service. If you are interested in purchasing 2011 aluminum tubes, please contact us immediately to get the latest quotation and stock status to help your project go smoothly.

Looking for easy-to-cut, high-strength aluminum tube materials? 2011 aluminum tubes are ideal for the automotive, aerospace, electronic equipment, precision machinery and other industries due to their excellent processing performance and excellent mechanical strength. Its excellent corrosion resistance and excellent electrical conductivity make it more suitable for high-demand applications such as electrical connectors and fasteners.

We offer a variety of specifications in stock and support custom processing! Contact us now to get a quote and solution!

FAQ

Is 2011 aluminum tube suitable for automatic lathe processing?

Yes, 2011 aluminum alloy is specially designed for automatic lathe processing and has extremely high cutting performance, making it an ideal lathe processing material.

Can 2011 aluminum tube provide certification that meets specific standards?

Yes, our 2011 aluminum tube products meet a variety of international quality standards and can provide certification documents.

Can 2011 aluminum tubes with different diameters be customized?

Yes, we support customization of different specifications and sizes to meet the specific needs of customers.