China 2014 Aluminum Strip Suppliers & Manufacturers

As a professional aluminum alloy material supplier, Huaxiao Metal has a long-term spot supply of high-performance 2014 aluminum strips. This alloy belongs to the Al-Cu-Mg series of aluminum alloys, with excellent strength, good processability, and outstanding fatigue resistance. It is widely used in aerospace structural parts, precision molds, machinery manufacturing, and high-strength components. We provide a variety of specifications and customized processing services to meet your diverse needs, from raw material procurement to project application.

Contact us now to get 2014 aluminum strip prices and technical support. Huaxiao Metal is one of the most trusted aluminum metal suppliers and manufacturers in China!

2014 Aluminum Strip Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

2014 Aluminum Strip Data Sheet

Equivalent Specifications of Aluminum 2014 Strip

Here is a table displaying the equivalent specifications for the Aluminum 2014 strip:

| Region | Specification | Description |

|---|---|---|

| United States | ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| AMS 4029 | Aluminum Alloy, Sheet and Plate, Alclad 4.4Cu – 1.5Mg – 0.60Mn (Alclad 2014-T6) | |

| AMS 4035 | Aluminum Alloy, Sheet and Plate, 4.4Cu – 1.5Mg – 0.60Mn (2014-T6 Flat Sheet and Plate) | |

| SAE J454 | Aluminum Alloys in the Form of Castings | |

| European Union | EN 485-2 | Aluminium and Aluminium Alloys – Sheet, Strip and Plate – Mechanical Properties |

| EN 573-3 | Aluminium and Aluminium Alloys – Chemical Composition and Form of Wrought Products – Part 3: Chemical Composition and Form of Products | |

| EN 515 | Aluminium and Aluminium Alloys – Wrought Products – Temper Designations | |

| International | ISO 6361-2 | Wrought Aluminium and Aluminium Alloy Sheets, Strips, and Plates – Part 2: Mechanical Properties |

| ISO 209 | Wrought Aluminium and Aluminum Alloys – Chemical Composition | |

| Japan | JIS H 4000 | Aluminum and Aluminum Alloy Sheets, Strips and Plates |

This table shows the various standards and specifications equivalent to Aluminum 2014 strips. If you want to know more news, you can contact us directly!

Chemical Composition of 2014 Aluminum Strips

| Element | Al | Cu | Mg | Mn | Si | Fe | Zn | Ti | Others |

|---|---|---|---|---|---|---|---|---|---|

| Percentage (%) | 90.7 – 94.7 | 3.9 – 5.0 | 0.2 – 0.8 | 0.4 – 1.2 | 0.5 – 1.2 | 0.7 max | 0.25 max | 0.15 max | 0.15 max each, 0.05 max total |

There are some differences in the chemical composition of aluminum products from different aluminum manufacturers, but they are all within a certain range. If you want to know more, please contact us directly!

Mechanical Properties of 2014 Aluminium Strips

Here is a table displaying the mechanical properties of 2014 aluminum strips in different tempers:

| Property | 2014-T3 | 2014-T4 | 2014-T6 | 2014-T651 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 415 | 400 | 485 | 485 |

| Yield Strength (MPa) | 275 | 275 | 415 | 415 |

| Elongation (%) | 13 | 15 | 10 | 10 |

| Hardness (Brinell) | 120 | 120 | 150 | 150 |

Notes:

- Tensile Strength: The maximum amount of tensile (pulling) stress that a material can withstand before failure.

- Yield Strength: The amount of stress at which a material begins to deform plastically.

- Elongation: A measure of how much a material can be stretched before breaking, expressed as a percentage of its original length.

- Hardness: A measure of a material’s resistance to deformation and wear, often assessed using the Brinell hardness test.

Physical Properties of 2014 Aluminum Strips

| Property | Value |

|---|---|

| Density | 2.80 g/cm³ |

| Melting Point | 502 – 638 °C |

| Thermal Conductivity | 138 W/m·K |

| Electrical Conductivity | 34% IACS (International Annealed Copper Standard) |

| Coefficient of Thermal Expansion | 23.2 µm/m·K |

| Modulus of Elasticity | 73.1 GPa |

| Specific Heat Capacity | 0.875 J/g·K |

| Poisson’s Ratio | 0.33 |

Tempers of 2014 Aluminum Strips

2014-O (Annealed): The material is fully annealed to achieve the lowest strength but highest ductility. This temper is suitable for deep drawing and complex forming operations.

2014-T3: The material is solution heat-treated and then cold worked. This process increases the material’s strength compared to the annealed temper while maintaining reasonable ductility and formability.

2014-T4: The material is solution heat-treated and then naturally aged. This temper balances strength and formability, making it suitable for applications that require moderate strength and good machinability.

2014-T6: The material is solution heat-treated and then artificially aged. This temper provides the highest strength among the common tempers, but it comes with reduced ductility. It is used in applications where high strength is critical.

2014-T651: Similar to the T6 temper, but includes a stress-relief process by stretching. This additional step helps improve dimensional stability and reduce residual stresses, making it ideal for precision components.

Choosing the appropriate temper depends on the specific requirements of the application, including the need for strength, ductility, machinability, and stress resistance.

Applications of 2014 Aluminum Strip Metal

Electrical Applications

Construction

Automotive Industry

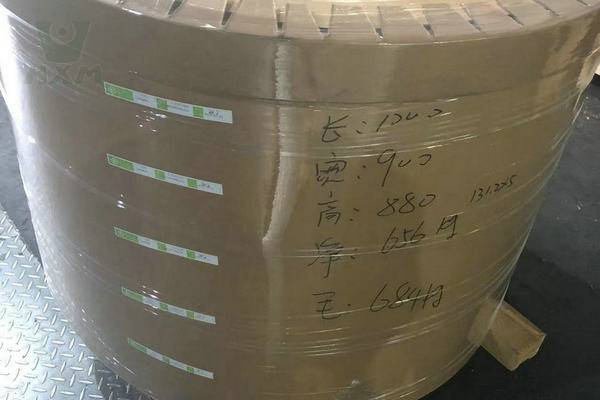

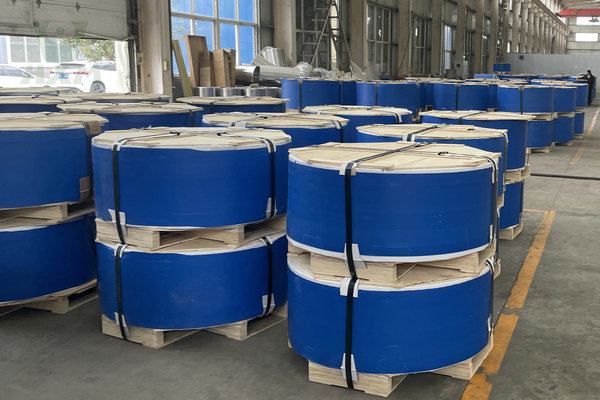

2014 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 2014 Aluminum Strip?

2014 Aluminum Strip is a flat, thin sheet of 2014 aluminum alloy that is rolled and cut from larger plates or sheets. This alloy is known for its high strength and excellent machinability, making it suitable for a variety of demanding applications, particularly in the aerospace and military industries.

2014 Aluminum Strip Compared with Other Materials:

Strength: 7075 aluminum alloy offers the highest strength, followed by 2024 and 2014, 6061 is lower in strength but offers better workability and corrosion resistance.

Ductility: 6061 offers the best ductility, while 2014 and 2024 have lower ductility.

Corrosion resistance: 6061 offers the best corrosion resistance, followed by 7075, 2014 and 2024 require additional coating protection.

Weldability: 6061 aluminum alloy has the best weldability, while 2014 and 2024 have poor weldability.

How Can I Get A Sample Of 2014 Aluminum Strips?

Yes, we can provide samples of 2014 aluminum strips for your testing. We can also provide samples of other materials. If you are not sure whether 2014 or other materials of aluminum strips meet your project requirements, you can contact us to get a sample.

2014 Aluminum Strip Characteristics:

High Strength: One of the highest-strength alloys available.

Machinability: Excellent, making it a preferred choice for complex parts.

Heat Treatable: Can be heat-treated to achieve various mechanical properties.

Corrosion Resistance: Moderate, often requiring a protective coating in corrosive environments.

Weldability: Fair, with some challenges in welding due to cracking.

Density: Approximately 2.80 g/cm³.

Thermal and Electrical Conductivity: Lower than that of pure aluminum but still significant.

2014 Aluminum Strip Considerations:

Heat Treatment: Various tempers can significantly change the properties of 2014 aluminum.

Corrosion Protection: Often needs an anodizing or other coating for improved corrosion resistance.

Working with 2014 Aluminum: Special considerations in terms of tooling and welding techniques may be necessary due to its properties.

Why Choose Us As Your 2014 Aluminum Strip Supplier?

If you are looking for a manufacturer and exporter of 2014 Aluminum Strip, I think we can be one of your Aluminum Narrow Strip suppliers! Here are some reasons why we think you can choose us:

Industry Time: We have been engaged in the metal industry for more than 10 years, with a professional manufacturing and export service team, advanced machinery and equipment, etc.

Competitive Product Prices: Due to our long history in this industry, we have long-term cooperation projects with many steel mills, so the quality and price of our products can be guaranteed. Our internal manufacturing efficiency has been improved, and we can produce more and better aluminum products in the same amount of time, thereby reducing our cost prices.

Excellent Customer Service: For first-time customers, we provide videos and on-site factory visits to increase customer trust. We accept payment methods such as TT, L/C, etc. Product warranty period is 5 years, etc.

Why not give us a chance to serve your project? I believe we can become one of your best and most trusted aluminum strip suppliers!