HXM offers 3003 aluminum wire, a versatile and durable aluminum alloy wire with excellent corrosion resistance and formability. This product is widely used in various industries and is the first choice for applications that require reliable and lightweight materials.

Whether you are looking for a 3003 aluminum wire supplier, exploring 3003 aluminum wire prices, or looking for a trusted aluminum wire partner to provide a stable inventory, our company can meet your needs.

3003 Aluminum WireSpecifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: HO,H12,H14,H16,H18,H19,H22,H24,H26,H28,F,H112,T651,T3,T451, T4,T6, ect.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: ASTM B221, B211, B316, B565 / ASME SB221, SB211, SB316, SB565, etc

Delivery Time: 7-20 days.

3003 Aluminum Wire Data Sheet

Equivalent Of Aluminum 3003 Wire

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

|---|---|---|---|---|---|---|

| AW-AlCu4Mg1 | AU4G1 | 3.0517 | A93003 | AlCu4Mg | 3003 | AlCuMg2 |

Chemical Composition of 3003 Aluminum Wires

| Element | Al | Mn | Cu | Si | Fe | Zn | Other Elements (each) | Other Elements (total) |

|---|---|---|---|---|---|---|---|---|

| Composition (%) | Balance | 1.0 – 1.5 | 0.05 – 0.20 | ≤ 0.60 | ≤ 0.70 | ≤ 0.10 | ≤ 0.05 | ≤ 0.15 |

3003 aluminum alloy wire has excellent corrosion resistance and good mechanical properties, mainly due to its manganese content.

Mechanical Properties and Tempers of 3003 Aluminum Wires

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Applications |

|---|---|---|---|---|

| H14 (Half-Hard) | 140-170 | 115 | 10-12 | Roofing, siding, chemical handling equipment |

| H24 (Half-Hard, Annealed) | 120-160 | 100 | 14-18 | Similar to H14, but with improved ductility due to annealing, suitable for more complex forming operations |

| O (Annealed) | 90-130 | 35 | 20 | Offers highest ductility, ideal for deep drawing, spinning, and other processes requiring significant deformation |

| H18 (Full-Hard) | 185-200 | 145 | 4-6 | Provides the highest strength with limited ductility, suitable for applications where high strength is critical and minimal forming is required |

For high-quality 3003 aluminum wires and professional assistance, contact HXM, your reliable supplier of aluminum products.

Applications of 3003 Aluminum Wire Metal

Electrical Wiring: Used where conductivity and resistance to environmental factors are important.

Heat Exchangers: Ideal for heat transfer applications due to their good thermal conductivity.

Braided Conductors: Utilized in electrical and thermal conductivity applications.

Automotive and Aerospace Components: Employed in areas where lightweight, strength, and corrosion resistance are required.

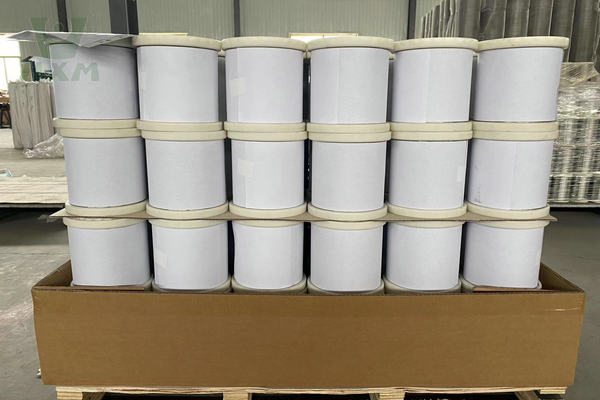

3003 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 3003 Aluminum Wire?

3003 aluminum wire is made from an aluminum-manganese alloy, specifically designated as 3003 in the Aluminum Association numbering system. This alloy is known for its excellent corrosion resistance, good machinability, and moderate strength, making it a popular choice for a variety of industrial and commercial applications.

Comparison Between 3003 Aluminum Wire and 5052 Aluminum Wire

Strength:

- 5052 Aluminum Wire: Has higher tensile and yield strength compared to 3003, making it more suitable for applications requiring greater mechanical strength.

- 3003 Aluminum Wire: While it has lower strength, it is sufficient for many applications and is easier to form.

Corrosion Resistance:

- Both 3003 and 5052 aluminum wires offer excellent corrosion resistance, but 5052 is particularly good in marine environments due to the presence of magnesium, which enhances its resistance to saltwater corrosion.

Formability:

- 3003 Aluminum Wire: Known for its excellent formability and is easier to work with, making it ideal for complex shapes and deep drawing applications.

- 5052 Aluminum Wire: While still good, its higher strength makes it slightly less formable compared to 3003.

Weldability:

- 3003 Aluminum Wire: Has excellent weldability, suitable for most welding techniques.

- 5052 Aluminum Wire: Also weldable, but requires more care and may need special procedures to avoid cracking due to its higher magnesium content.

Applications:

- 3003 Aluminum Wire: Commonly used in applications where moderate strength and high formability are required, such as in chemical equipment, storage tanks, and cookware.

- 5052 Aluminum Wire: Preferred for applications needing higher strength and better corrosion resistance, such as in marine environments, pressure vessels, and aerospace components.

Comparison Between 3003 Aluminum Wire and 6061 Aluminum Wire

Strength:

- 6061 Aluminum Wire: Significantly higher tensile and yield strength compared to 3003, making it suitable for more demanding structural applications.

- 3003 Aluminum Wire: Lower strength but sufficient for many general-purpose applications, with excellent formability.

Corrosion Resistance:

- 3003 Aluminum Wire: Excellent corrosion resistance, particularly in environments exposed to moisture and chemicals.

- 6061 Aluminum Wire: Good corrosion resistance, but not as high as 3003, especially in marine environments.

Formability:

- 3003 Aluminum Wire: Known for its excellent formability, easy to shape into complex geometries.

- 6061 Aluminum Wire: Good formability but not as high as 3003 due to its higher strength.

Weldability:

- Both 3003 and 6061 aluminum wires have excellent weldability, but the techniques and filler materials used may vary to prevent issues like cracking in 6061 due to their higher strength and silicon content.

Applications:

- 3003 Aluminum Wire: Often used in applications where moderate strength and high formability are required, such as in chemical equipment, storage tanks, and cookware.

- 6061 Aluminum Wire: Preferred for applications requiring higher strength and good machinability, such as in structural components, automotive parts, and aerospace applications.

How Can I Get A Sample Of 3003 Aluminum Wires?

You can contact us directly and tell us the size and quantity of the 3003 aluminum wire samples you need, and we will send you the samples.

Environmental Protection and Sustainability:

Our production process strictly adheres to environmental protection standards and is committed to reducing environmental impact. Our 3003 aluminum wire is 100% recyclable and meets the requirements of sustainable development.

Common Tempers of 3003 Aluminum Wire

O (Annealed): Maximum ductility, used for deep drawing and forming applications.

H14 (Half-Hard): Good balance of strength and formability, suitable for general-purpose applications.

H24 (Half-Hard, Annealed): Improved ductility due to partial annealing, used in more complex forming operations.

H18 (Full-Hard): Maximum strength with limited ductility, used where high strength is critical.

Why Choose Us As Your 3003 Aluminum Wire Supplier?

There are many manufacturers and suppliers of aluminum metal in China, so why choose us as your aluminum wire supplier? Here are some of the advantages we recommend you to choose us as your 3003 aluminum wire supplier:

Quality Assurance

- Stringent Quality Control: Our 3003 aluminum wire undergoes rigorous quality checks at every stage of production to ensure it meets the highest industry standards.

- Certified Materials: We source our aluminum from reputable suppliers and provide certification and traceability for all materials used.

Extensive Experience

- Industry Expertise: With years of experience in the aluminum industry, we have developed deep knowledge and expertise in manufacturing and supplying high-quality aluminum wire.

- Technical Support: Our team of experts is available to provide technical support and guidance on selecting the right aluminum wire for your specific application.

Custom Solutions

- Tailored Specifications: We offer customizable options for our 3003 aluminum wire, including various diameters, lengths, and surface treatments to meet your unique requirements.

- Special Orders: Whether you need specific temper conditions or custom packaging, we can accommodate special orders to suit your needs.

Competitive Pricing

- Cost-Effective Solutions: We strive to offer competitive pricing without compromising on quality, ensuring you receive the best value for your investment.

- Bulk Discounts: We provide attractive discounts for bulk orders, helping you save on large-scale projects.

Fast and Reliable Delivery

- Efficient Logistics: Our efficient logistics network ensures timely delivery of your orders, minimizing downtime and keeping your projects on schedule.

- Global Reach: We can supply 3003 aluminum wire to customers worldwide, ensuring you receive your products wherever you are.

Sustainability Commitment

- Eco-Friendly Practices: We are committed to sustainable manufacturing practices, including recycling and reducing waste, to minimize our environmental impact.

- Compliance: Our products comply with environmental regulations and standards, ensuring responsible sourcing and production.

Excellent Customer Service

- Responsive Support: Our dedicated customer service team is available to assist you with any inquiries, from product selection to after-sales support.

- Customer Satisfaction: We prioritize customer satisfaction and strive to build long-term relationships based on trust and reliability.

By choosing us as your 3003 Aluminum Wire Supplier, you will be working with a reliable, experienced, customer-focused company that is committed to providing high-quality aluminum metal products and exceptional service.