China 1350 Aluminum Sheet Suppliers

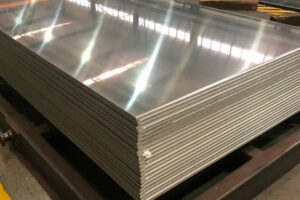

1350 Aluminum Sheet is the top choice for industries that require high electrical conductivity, lightweight material, and excellent formability. As one of the leading suppliers and manufacturers of aluminum products, we offer quality 1350 aluminum sheets at competitive prices and have a large inventory for quick delivery. Whether you need aluminum sheet for electrical wires, transformer windings, or industrial machinery, our 1350 Aluminum Sheet can meet your requirements.

1350 Aluminium Sheets Specifications

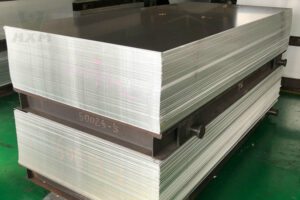

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: O, H14, H18, H19, H26, H112, etc.

Delivery Time: 7-20 days.

Standards: ASTM B209 / ASME SB209/DIN 1725/JIS H4000

As trusted aluminum sheet suppliers, we ensure that our 1350 Aluminum Sheets meet international standards, including ASTM B209 and AMS 4006. Our manufacturers use advanced production techniques to deliver sheets with consistent quality, precise dimensions, and excellent surface finishes.

Description of 1350 Aluminum Sheet & Plate

We are one of the best 1350 aluminum sheet suppliers in China. 1350 aluminum alloy is known for its excellent electrical conductivity, making it the material of choice for applications that require superior electrical performance. This alloy has high corrosion resistance and excellent ductility, ensuring that it meets the diverse needs of various industries.

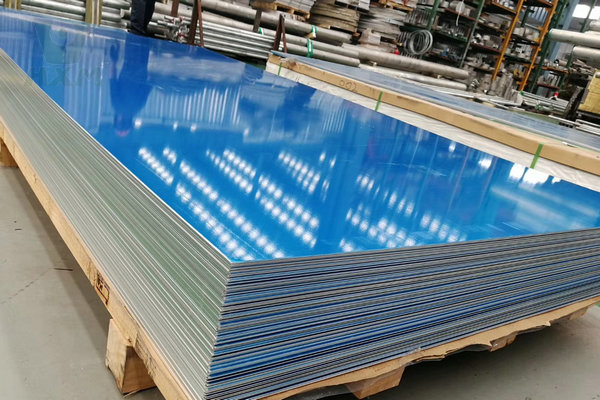

Our 1350 aluminum sheets and plates are ideal for use in power distribution systems, including busbars, transformers, and high-voltage wires. They are also well suited for the automotive, aerospace, and renewable energy sectors, providing reliable performance in electrical connectors, motor windings, and solar panel systems.

At HXM, we are committed to providing high-quality 1350 aluminum products that meet your specific needs. For detailed product information and pricing, please contact us today.

1350 Aluminum Sheets & Plates Data Sheet

Equivalent Specifications of Aluminium 1350 Sheet & Plate

Below is a table listing the equivalent specifications of the Aluminium 1350 Sheet & Plate:

| Standard | Specification/Designation |

|---|---|

| UNS | A91350 |

| ISO | Al 99.5 |

| ASTM | B209 |

| EN | AW-1350 |

| JIS | A1350P |

| GB/T (China) | 1350 |

| AA | 1350 |

| CSA | 1350 |

These specifications ensure that the 1350 aluminum sheet and plate you receive from HXM meet the necessary standards for quality and performance. For more information or to request a quote, please contact us today.

Chemical Composition of 1350 Aluminum Plates

The chemical composition of 1350 aluminum plates is primarily composed of aluminum with minimal alloying elements. Here is the detailed breakdown:

| Element | Percentage (% by weight) |

|---|---|

| Al | 99.50 min |

| Cu | 0.05 max |

| Fe | 0.40 max |

| Si | 0.10 max |

| Mn | 0.01 max |

| Zn | 0.05 max |

| Ti | 0.02 max |

| Others, each | 0.03 max |

| Others, total | 0.10 max |

The high purity of aluminum in 1350 alloy ensures excellent electrical conductivity and corrosion resistance, making it suitable for a variety of industrial and electrical applications. If you want to know more or need 1350 aluminum plate prices, please contact HXM, one of the reliable 1350 aluminum plate suppliers in China.

Mechanical Properties of 1350 Aluminium Sheets

| Property | Value |

|---|---|

| Tensile Strength | 90 – 125 MPa (13 – 18 ksi) |

| Yield Strength | 34 – 41 MPa (5 – 6 ksi) |

| Elongation | 25% – 30% |

| Hardness (Brinell) | 20 – 25 HB |

| Modulus of Elasticity | 69 GPa (10,000 ksi) |

| Density | 2.70 g/cm³ (0.0975 lb/in³) |

These properties make 1350 aluminum sheets suitable for applications that require good formability and electrical conductivity, such as electrical components and power distribution systems. Contact China 1350 aluminum sheet supplier HXM to get 1350 aluminum sheet prices!

Physical Properties of 1350 Aluminum Plates

The physical properties of 1350 aluminum plates are essential for understanding its behavior in various applications. Here are the key physical properties:

| Property | Value |

|---|---|

| Density | 2.70 g/cm³ (0.0975 lb/in³) |

| Melting Point | 646 – 657°C (1195 – 1215°F) |

| Thermal Conductivity | 235 W/m·K (1360 BTU in/ft²·hr·°F) |

| Coefficient of Thermal Expansion | 23.1 µm/m·°C (12.8 µin/in·°F) |

| Electrical Conductivity | 61% IACS |

| Specific Heat Capacity | 0.897 J/g·°C (0.214 BTU/lb·°F) |

| Modulus of Elasticity | 69 GPa (10,000 ksi) |

| Poisson’s Ratio | 0.33 |

1350 Aluminum Sheet is ideal for applications requiring excellent electrical and thermal conductivity along with good formability. Contact HXM for 1350 Aluminum Sheet pricing!

Tempers of 1350 Aluminum Plates

Below is a table summarizing the different tempers of 1350 aluminum sheets and their brief descriptions:

| Temper | Description | Applications |

|---|---|---|

| O | Annealed, softest temper, maximum ductility, and workability | Deep drawing, bending, forming |

| H12 | Strain-Hardened, Half-Hard, increased strength, good ductility | Moderate strength applications, structural components, electrical parts |

| H14 | Strain-Hardened, 1/2 Hard, balance of strength and formability | Automotive, construction components |

| H18 | Strain-Hardened, Full Hard, high strength, reduced ductility | Electrical conductors, structural applications |

| H19 | Extra Hard, maximum achievable strength through significant cold working | High-strength requirements with minimal deformation |

| F | As Fabricated, no special control over thermal or mechanical treatment | General-purpose applications |

HXM offers a wide range of 1350 aluminum sheets in different conditions to suit your specific needs. Contact us today to discuss your requirements and get a quote from the best 1350 aluminum sheet suppliers in China.

1350 Aluminum Sheet & Plate Application

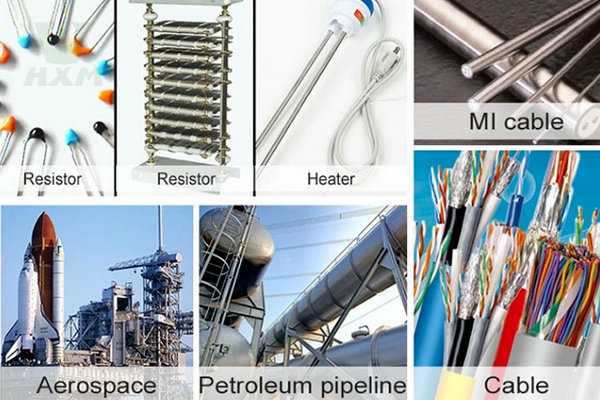

The 1350 aluminum alloy is notable for its high electrical conductivity, making it ideal for applications where electrical performance is crucial. Here are some common applications for 1350 aluminum sheets and plates:

Electrical and Electronics:

- Bus Bars: Due to its excellent conductivity, 1350 aluminum is commonly used in bus bars for electrical distribution systems.

- Transformers: The alloy is used in transformer windings and cores, where efficient electrical performance is essential.

- Power Grids: High-voltage power lines and electrical grid components benefit from the alloy’s properties.

Transportation:

- Rail Transport: Components like electrical connectors and conductors in rail transport systems.

- Automotive: Used in certain electrical components and connectors within vehicles.

Industrial:

- Electrical Enclosures: Used for making protective enclosures for electrical systems.

- Motor Windings: Utilized in the windings of electric motors.

Aerospace:

- Aircraft Electrical Systems: Incorporated in electrical wiring and components in aircraft.

Renewable Energy:

- Solar Panels: Electrical connectors and components in solar panel systems.

- Wind Turbines: Used in electrical systems within wind turbines.

Other Applications:

- Heat Exchangers: Leveraged in applications requiring good thermal conductivity

We have a large inventory so we can fulfill orders quickly, reducing lead times and keeping your project on track.

Whether you need a small batch prototype or a large industrial production order, we can meet your needs. Contact us today to get a quote for 1350 aluminum sheet and check stock availability.